Rotation driving docking mechanism with fault tolerance characteristic

A technology of rotating drive and docking mechanism, applied in the direction of connecting components, mechanical equipment, etc., can solve the problems of strict accuracy requirements and docking failure, and achieve the effect of improving accuracy, not easy to exit, and easy to enter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

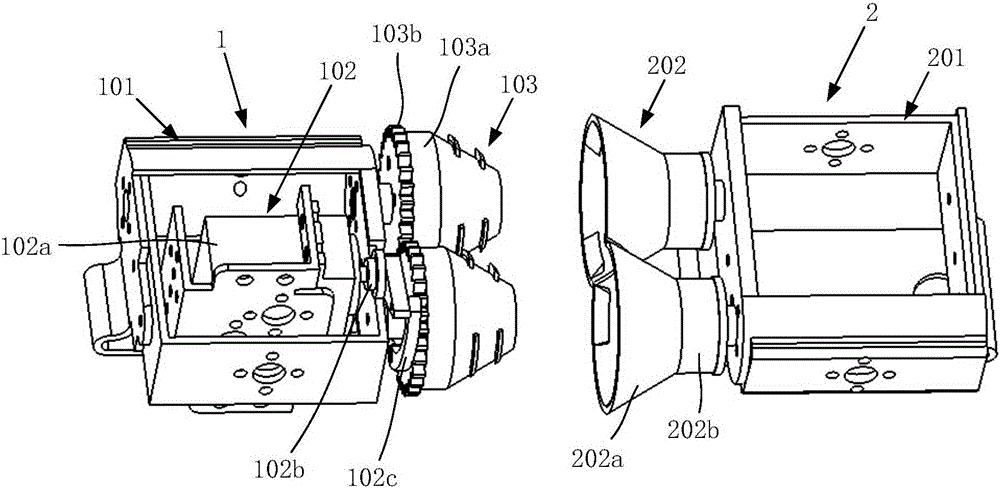

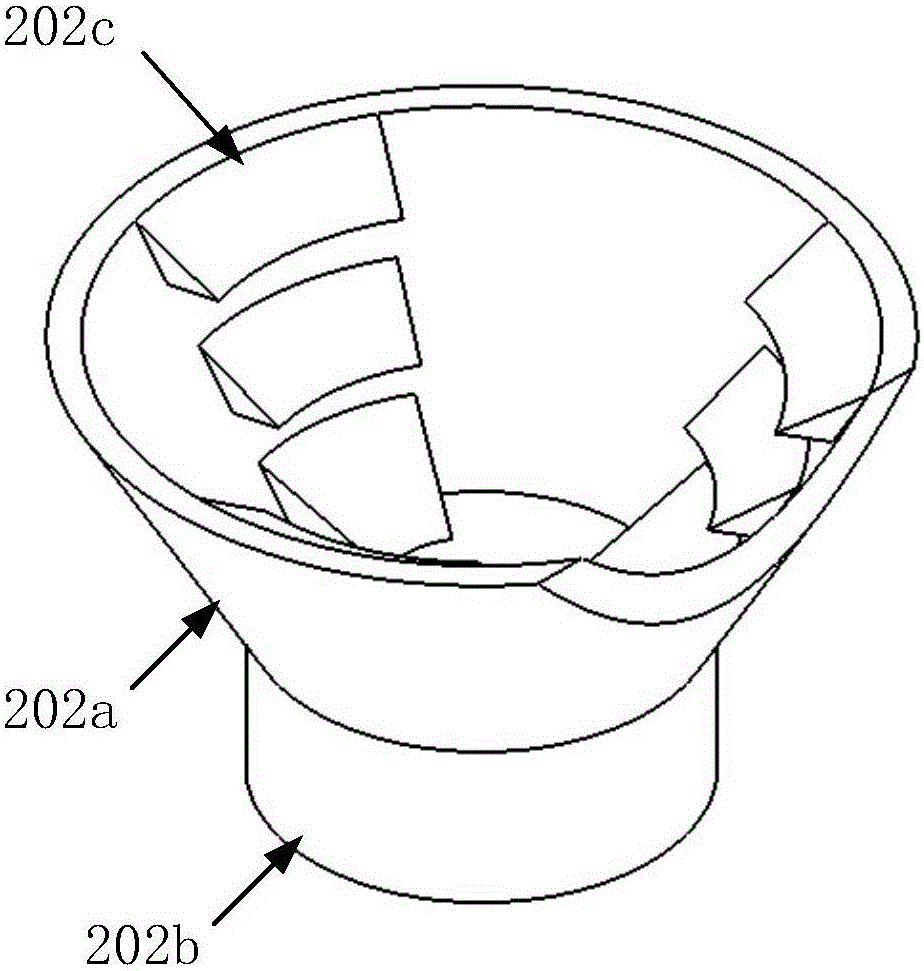

[0025] The rotary drive docking mechanism with fault-tolerant characteristics of the present invention includes a docking actuator 1 and a docking positioning mechanism 2, such as figure 1 shown.

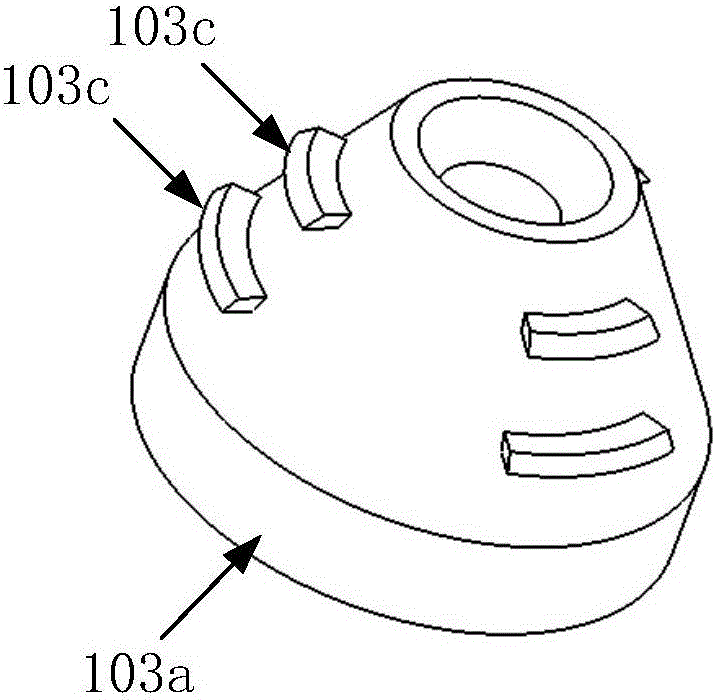

[0026] The docking actuator 1 includes an actuator frame 101, a driving mechanism 102 and a docking rotary head 103; two actuator connecting shafts are designed at the end of the actuator; the connecting axes of the two actuators are parallel and located on the same horizontal plane. There are two docking rotary heads 103, which are respectively installed on the connecting shafts of the two actuators. The two docking rotary heads 103 have the same structure, including a rotary head 103a and a transmission gear 103b; wherein, the rotary head 103a adopts a truncated conical structure, and the bottom end is coaxially fixed to the end of the connecting shaft of the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com