Double-arm robot system in plug-in mounting production and intelligent control method of double-arm robot system

A robot system and intelligent control technology, applied in computer control, program control, general control system, etc., can solve the problem of not being able to avoid joint angle limit, avoiding obstacles, self-correcting ability, poor reliability, and unable to meet real-time requirements and other problems to achieve the effect of simple structure, high operating efficiency and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof:

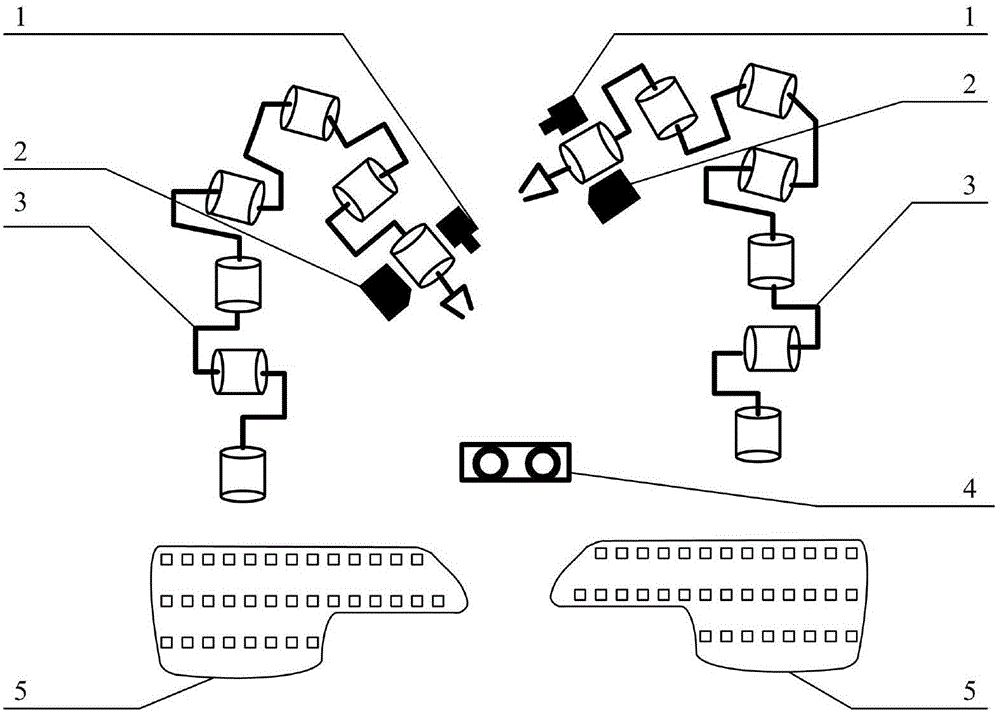

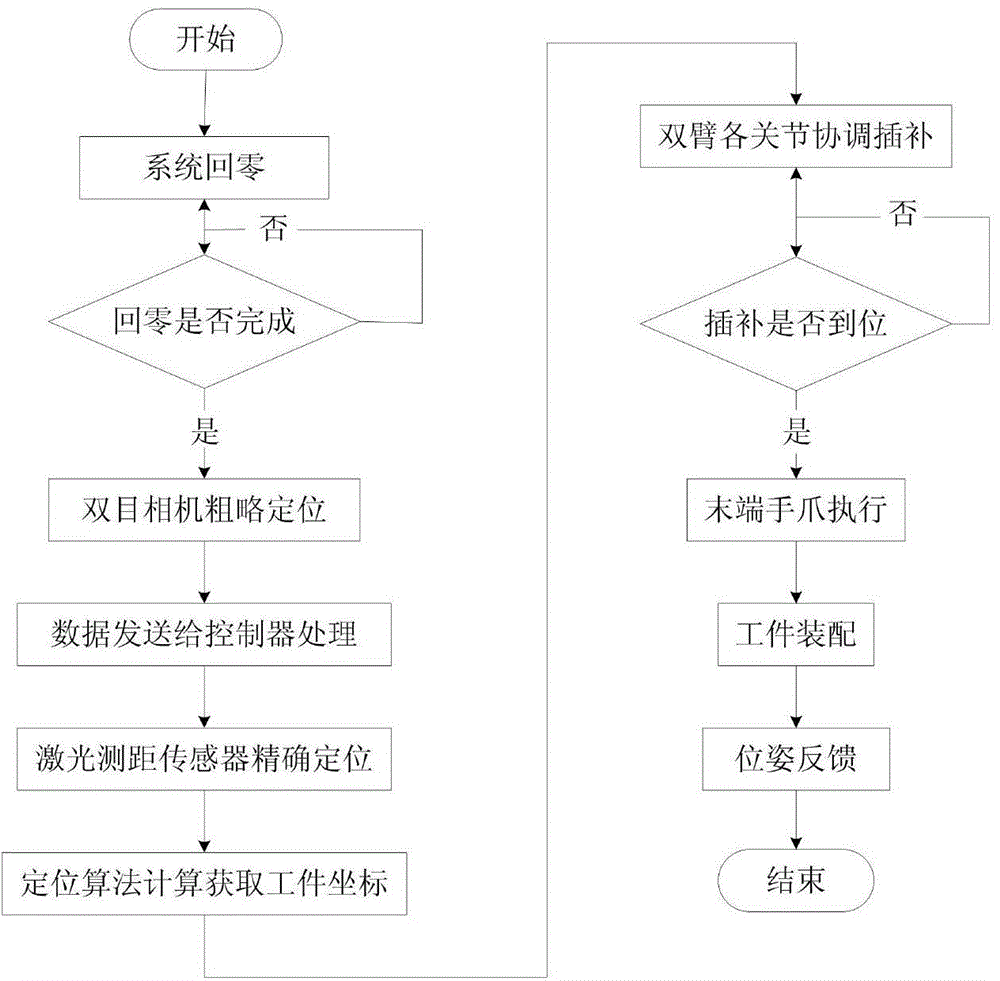

[0017] Such as Figure 1 to Figure 2 As shown, the dual-arm robot system in the plug-in production of the present invention includes two industrial cameras 1, two laser ranging displacement sensors 2, two robot arms 3, binocular vision 4 and two LED plug-in boards 5, the The control layer of the system is composed of industrial computer and high-speed Ethercat bus.

[0018] The dual-arm industrial robot system includes three aspects of movement, one is the movement of the waist pitch axis; the other is the coordinated movement of the two arms; the third is the movement of the terminal underactuated gripper. The waist is pitched, and the two arms are coordinated to complete the precise positioning of the end position; the end pose is adjusted in real time through the camera, and the movement of the end claw is adjusted to realize the grasping and insertion of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com