Firmly fixed screw group

A screw group, firm technology, applied in the directions of screws, nuts, bolts, etc., can solve the problems of easy loosening and insufficient firmness, and achieve the effect of not easy to loosen, fixed firmly, and avoid shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

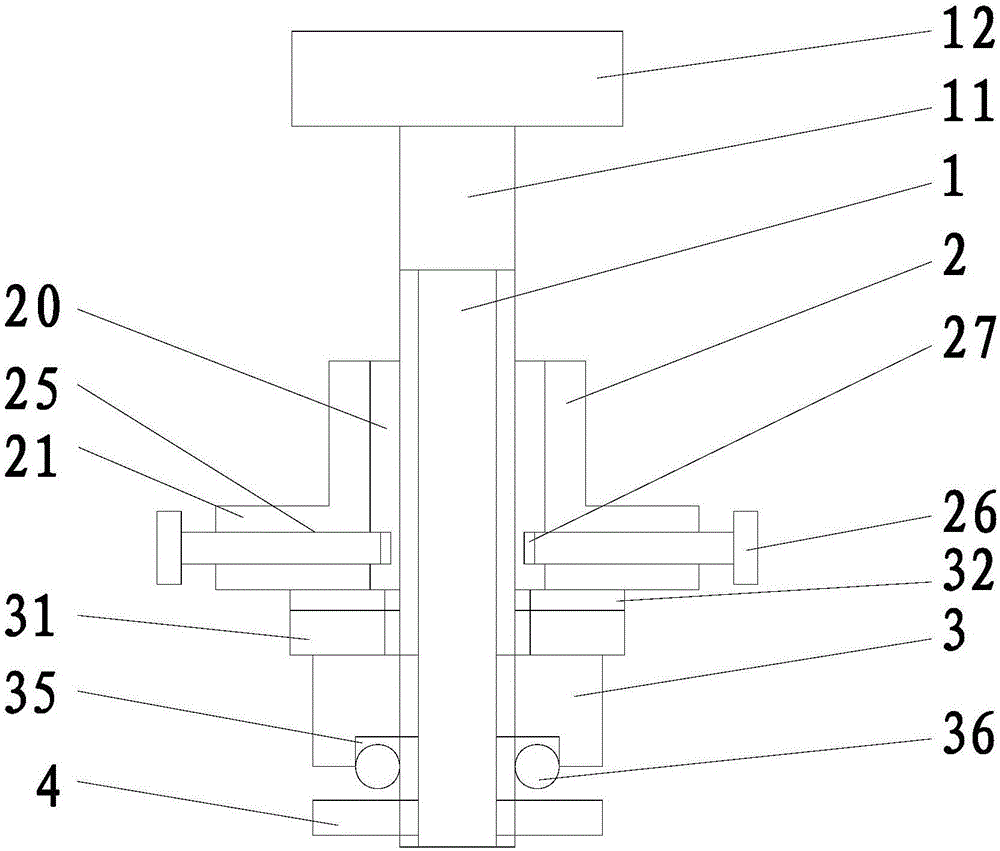

[0015] refer to figure 1 , a firmly fixed screw set of the present invention includes a screw 1, a polished rod 11, a first cross bar 12, a sleeve 2, a second cross bar 21, and a nut 3. One end of the screw 1 is fixed with a polished rod 11, and the polished rod 11 The end portion is fixed with a first cross bar 12, a nut 3 is screwed on the screw rod 1, an anti-slip sheet 31 is provided on the side of the nut 3 near the polished rod 11, and the end of the anti-slip sheet 31 is provided with a self-locking rib 32. A circular groove 35 is provided on the side away from the polished rod 11, and an annular elastic ring 36 is placed in the groove 35. A pressing plate 4 is screwed on the screw rod 1, and the pressing plate 4 is located on the side of the nut 3 away from the polished rod 11. The nut 3 and the second A sleeve 2 is arranged between a cross bar 12, and the sleeve 2 is sleeved on the screw rod 1, and a second cross bar 21 is fixed at one end of the sleeve 2, and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com