A gearbox oil level observation device and its assembly method

A technology of observation device and assembly method, which is applied to transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problems of inconvenient observation of oil level and low accuracy, and achieve convenient observation, high accuracy, and improved The effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

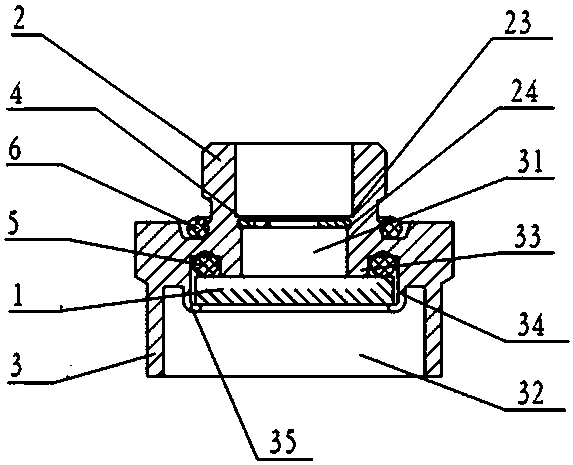

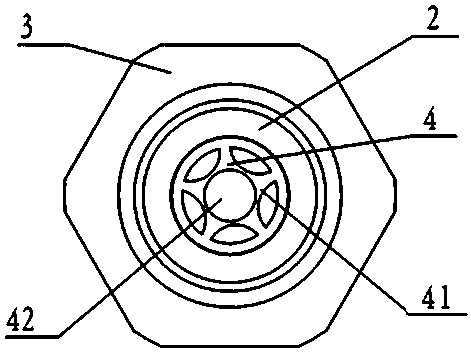

[0047] See Figure 1 to Figure 7 , A gearbox oil level observation device, comprising an inner plug 2, an outer plug 3 and a star metal bracket 4, the star metal bracket 4 includes a plurality of interconnected sub-frames 41, the bottom of the plurality of sub-frames 41 Are connected to each other to enclose a central hole 42, the tops of the multiple sub-frames 41 are evenly distributed along the same circle, and the circle where the tops of the multiple sub-frames 41 are located is concentrically arranged with the central hole 42;

[0048] The inner plug 2 is provided with an inner front cavity 21 and an inner rear cavity 22 coaxial with the inner plug 2 and an outer front cavity 31 and an outer front cavity 31 coaxial with the outer plug 3 are opened inside the outer plug 3 The posterior cavity 32, the inner anterior cavity 21 communicate with the outer posterior cavity 32 through the inner posterior cavity 22 and the outer anterior cavity 31 in turn. The junction of the outer...

Embodiment 2

[0050] The basic content is the same as Example 1, the difference is:

[0051] The outer plug 3 is provided with a No. 1 extension end 33 and a No. 2 extension end 34 inside, the top of the No. 1 extension end 33 is connected to the bottom wall of the inner plug 2, and the side of the No. 1 extension end 33 is provided There is an outer ring groove 51 to install the outer O-ring 5, the top of the outer O-ring 5 is in contact with the top wall of the outer ring groove 51, and the bottom of the outer O-ring 5 is connected to the transparent sheet 1 (can be a transparent tempered glass plate) The transparent sheet 1 is located in the sheet cavity 11 formed by the first extension end 33, the side wall of the outer plug 3, and the second extension end 34. The bottom of the transparent sheet 1 is in contact with the top of the inner end of the inner leg 35. The outer end of the leg 35 is connected with the bottom of the No. 2 extension end 34, and the top of the No. 2 extension end 34 ...

Embodiment 3

[0053] The basic content is the same as Example 1, the difference is:

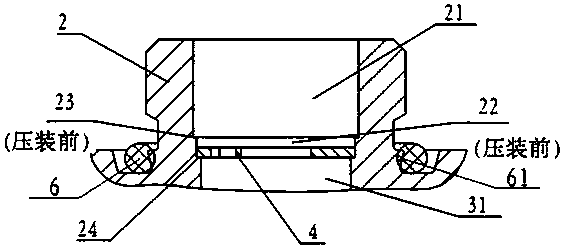

[0054] In an assembling method of the aforementioned gearbox oil level observation device, the star-shaped metal bracket 4 is installed according to the following steps:

[0055] First take a star-shaped metal bracket 4 to be installed. When assembling, first install the lower end surface of the star-shaped metal bracket 4 on the positioning step of the star-shaped metal bracket 4 between the inner rear cavity 22 and the outer front cavity 31, that is, the outer step 24 Then use a press tool to press the inner step 23 between the inner front cavity 21 and the inner rear cavity 22. Under the action of the pressure, the body material at the inner step 23 is subjected to squeezing force, and the body material is destroyed, deformed, Stacked on the star-shaped metal bracket 4, thereby fixing the star-shaped metal bracket 4 on the outer step 24, and the assembly can be completed at this time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com