Pipeline device for car air conditioning system

A technology for automotive air-conditioning systems and pipelines, applied in the direction of pipes/pipe joints/fittings, sockets/sockets, passing components, etc., can solve problems such as easy damage, hidden environmental hazards, and difficult operation, and reduce manpower , Avoid uneven glue application and reduce failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation of the pipeline device for the automobile air-conditioning system provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

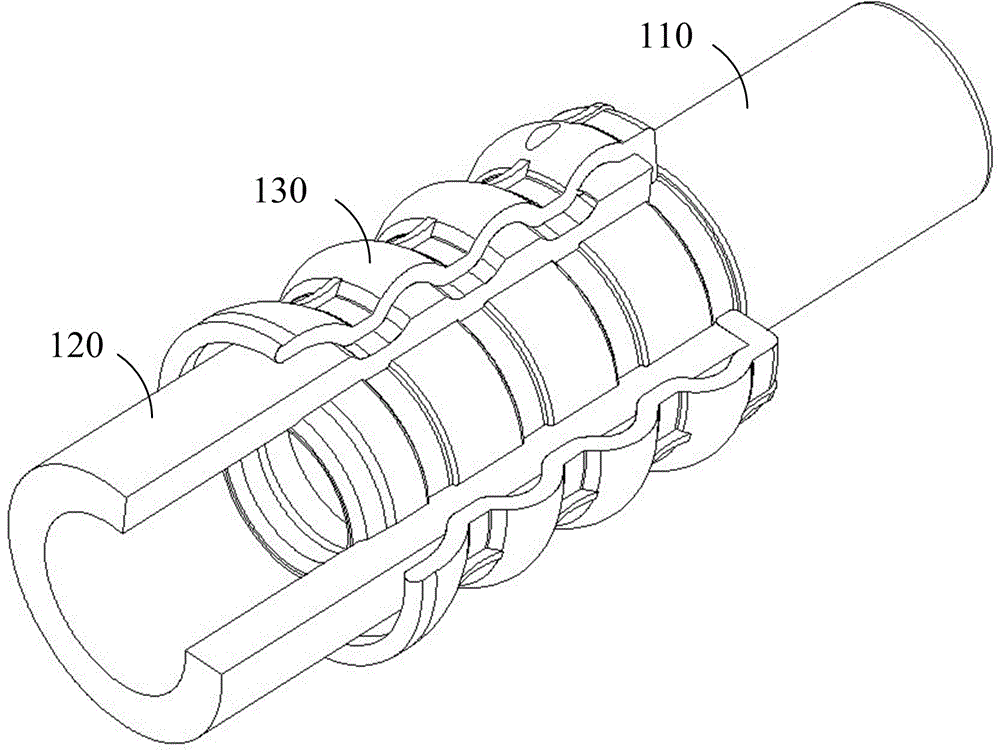

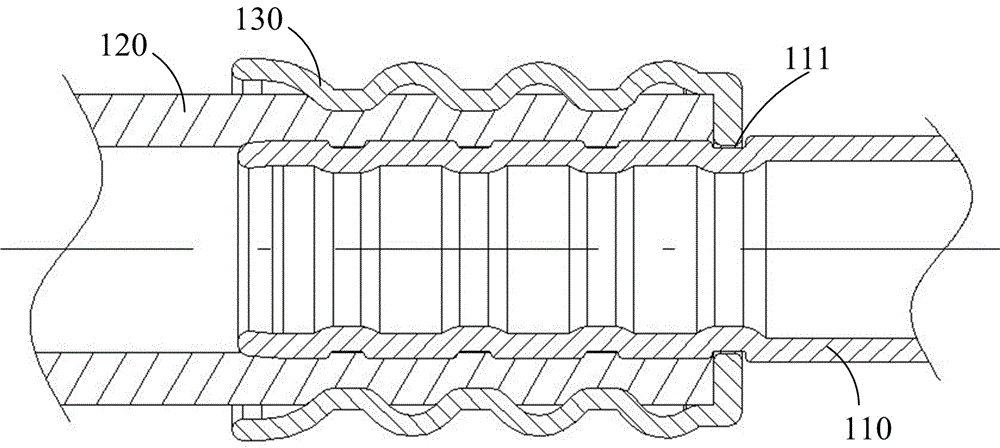

[0031] see figure 2 and image 3 , In one embodiment of the present invention, a pipeline device for an automobile air-conditioning system is provided, which includes: a metal tube 210 , a rubber tube 220 and a metal buckle sleeve 230 . The metal tube 210 , the rubber tube 220 and the metal buckle sleeve 230 are generally in the shape of a circular tube.

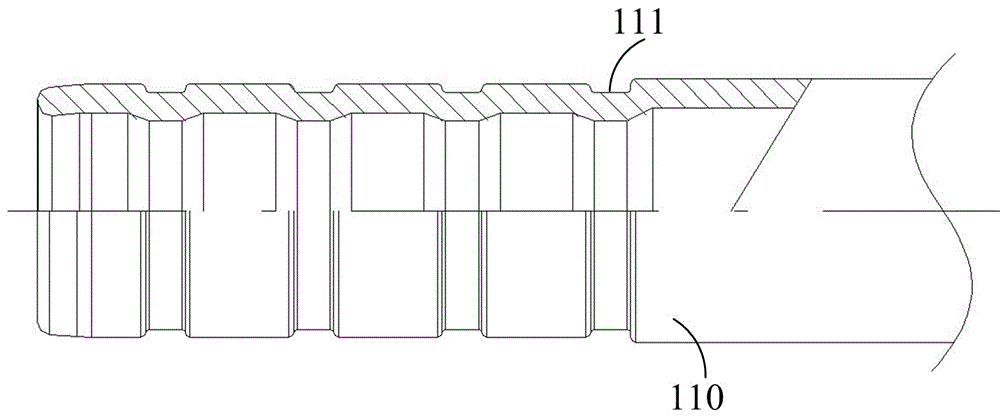

[0032] The metal tube 210 includes a metal tube body 211 and an extension 212 connected to the metal tube body 211 . The extension part 212 extends along the axial direction of the metal pipe body 211, and the intersection of the metal pipe body 211 and the extension part 212 forms a stepped surface 215, and the outer diameter D1 of the extension part 212 is smaller than the The outer diameter D2 of the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com