Point location accuracy evaluation method for gantry drilling machine tool

A precision evaluation and machine tool technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of difficult analysis of factors affecting the accuracy of machine tools, cumbersome operations, and difficulty in guaranteeing machining accuracy, and meet the requirements of point accuracy appraisal and measurement. And the calculation method is simple and the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The point accuracy evaluation method of the gantry hole making machine tool according to the present invention will be described in detail below with reference to the accompanying drawings.

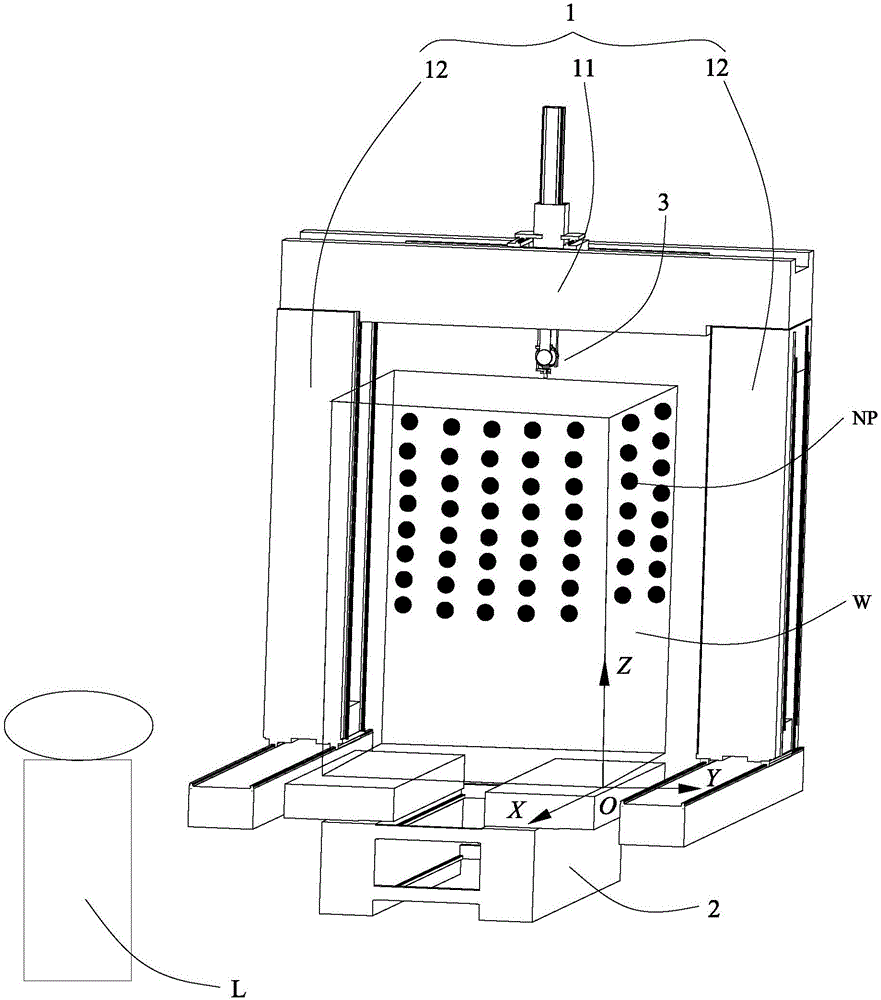

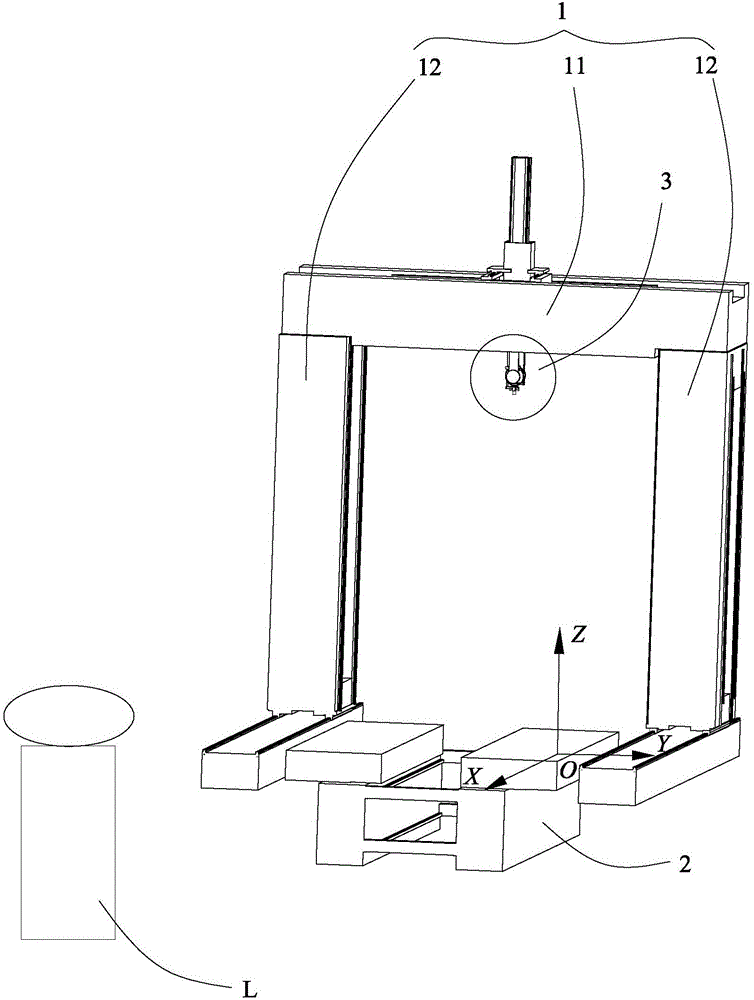

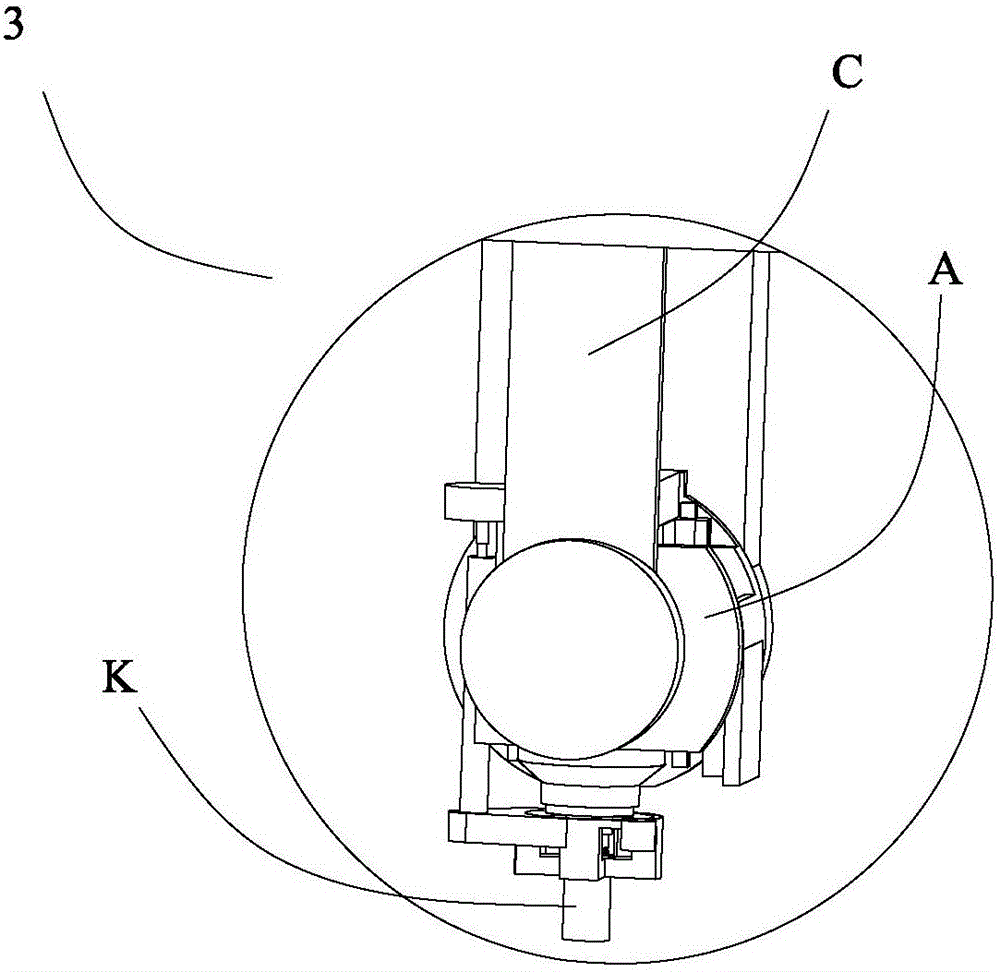

[0031] refer to Figure 1 to Figure 6 , the point accuracy evaluation method of the gantry hole making machine tool is used to evaluate the point accuracy of the gantry hole making machine tool including the tool K, the first rotation axis A and the second rotation axis C, including steps S1, S2, S3 and S4.

[0032] S1, construct the theoretical processing point NP of the tool K under the global coordinate system O-XYZ of the gantry hole making machine tool, and obtain the position coordinate NP of the theoretical processing point NP i =[x i ,y i ,z i ] T and the unit tool axis vector V when the tool K is at this position i =[I i ,J i , K i ] T , where I i , J i and K i are the vectors of the tool axis of the tool K on the X-axis, Y-axis, and Z-axis of the gantry hole-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com