Propeller thrust measuring device

A technology of measuring devices and propellers, which is applied in the direction of measuring devices, outboard propulsion devices, propulsion device engines, etc., can solve the problems of insufficient balance integration, time-consuming and laborious, and inaccurate data, and achieve high practical value, accurate measurement, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

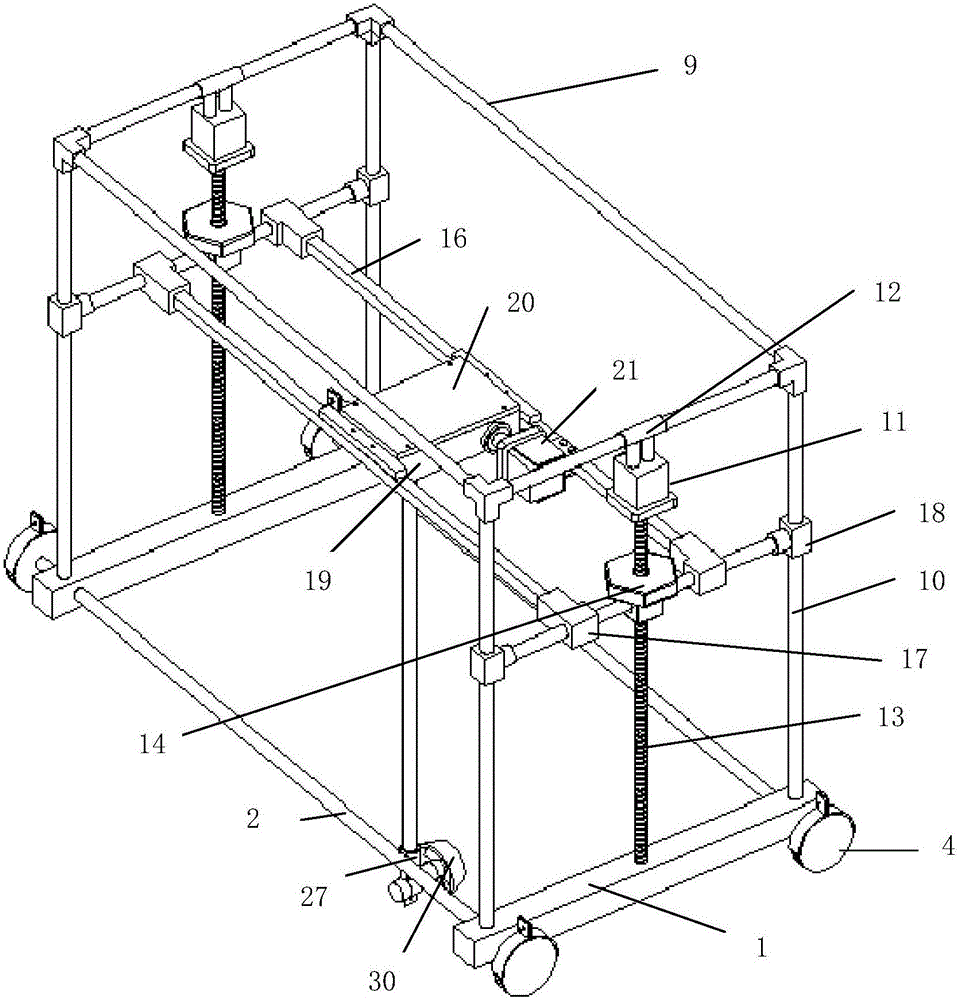

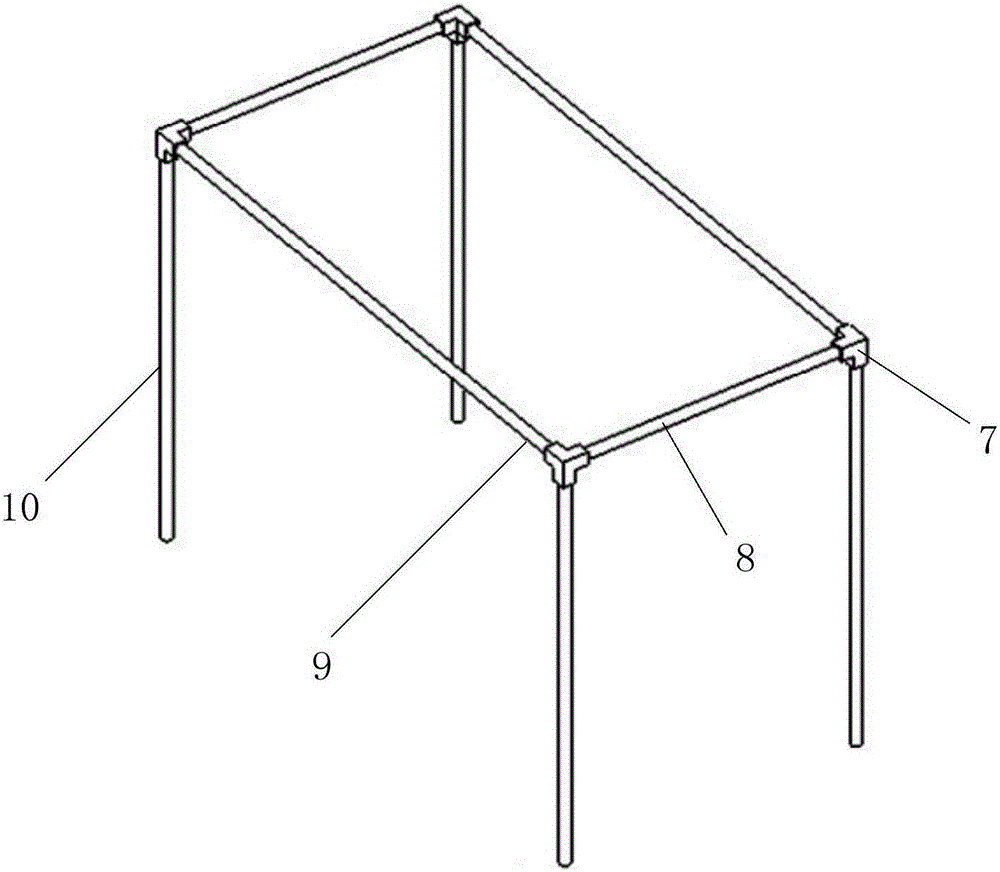

[0019] combine Figure 1 to Figure 7 , the present invention includes a base, an upper frame, two screw systems, a worm gear system and a measuring system. Sliding on the rod, the worm system and the measuring system are fixed on the screw system to control the rotation.

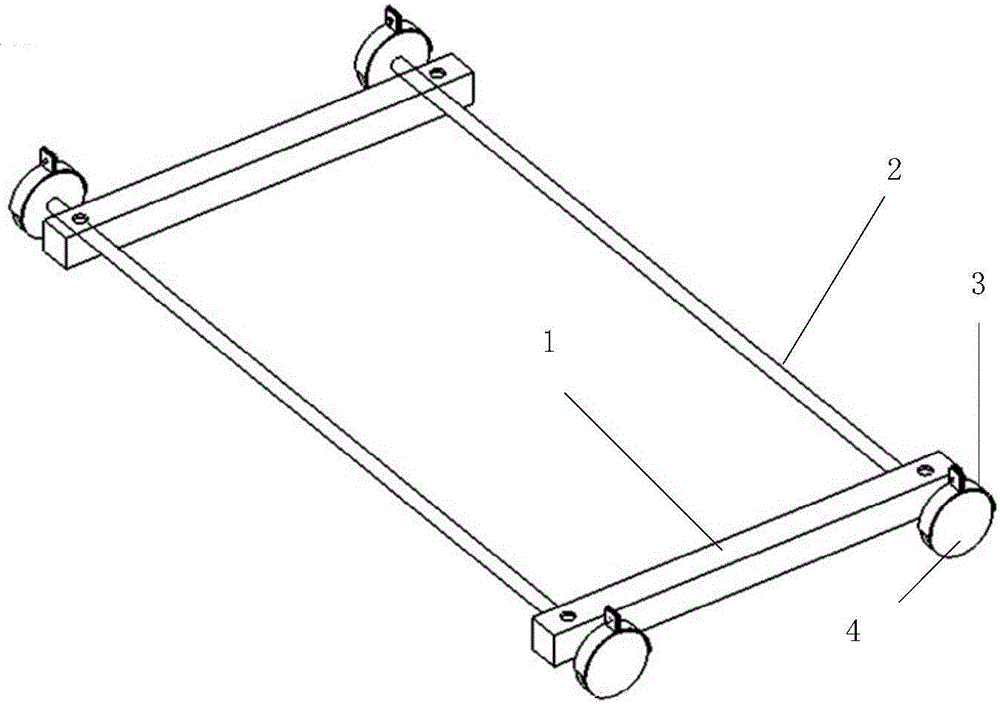

[0020] The base is composed of two support rods 1, two shafts 2, a locking device 3 and four bearing wheels 4. The structure is similar to the chassis part of a four-wheeled automobile. The four load-bearing wheels are divided into two groups, which are respectively connected to the shafts. The two groups are arranged symmetrically. Both shafts pass through the bracket and can rotate freely in the bracket. figure 2 shown. Fastening devices such as image 3 As shown, it consists of locking device 3, locking device 5 and locking screw 6. The load-bearing wheels ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com