Rolling bearing fault diagnosis method based on variational mode decomposition

A technology of variable mode decomposition and variational mode decomposition, applied in mechanical bearing testing, character and pattern recognition, testing of mechanical components, etc., can solve problems such as lack of theoretical basis, mode mixing, and inability to correctly separate components , to achieve the effect of suppressing spectrum noise and highlighting fault information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

[0050] The hardware environment used for implementation is an ordinary computer, and the software environment is: Matlab R12 and Windows 8. We have realized the method that the present invention proposes with Matlab software. The analyzed signal comes from the bearing fault test bench. The original vibration signal is measured with a sampling frequency of 32768Hz through the acceleration sensor installed on the bearing seat. The rolling bearing model is MB ER-10K, and the speed is 2100 rpm (f r =35Hz).

[0051] refer to figure 1 , figure 1 It is an algorithm flowchart of the method of the present invention, and the specific implementation also needs to include the following steps:

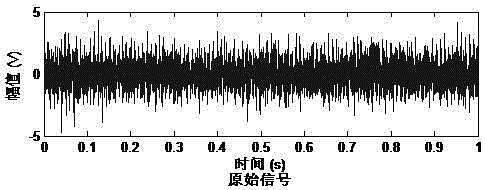

[0052] (1) Obtain the vibration signal of the tested bearing through the acceleration sensor. Such as figure 2 shown;

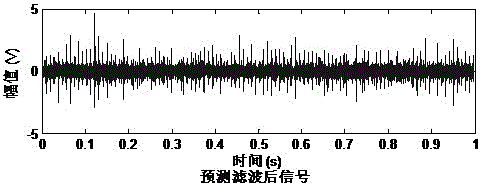

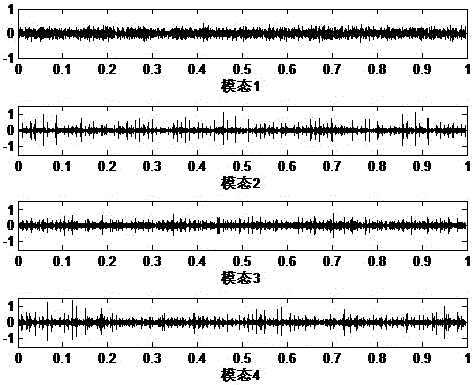

[0053] (2) Use the predictiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com