Method for testing three-dimensional ground stress by aid of acoustic emission processes

A test method, the technology of acoustic emission method, applied in the direction of applying stable tension/pressure to test material strength, measuring force, measuring device, etc., can solve problems affecting popularization and application, difficult identification of Kaiser effect points, fixed sampling angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be further described below in conjunction with the drawings and embodiments:

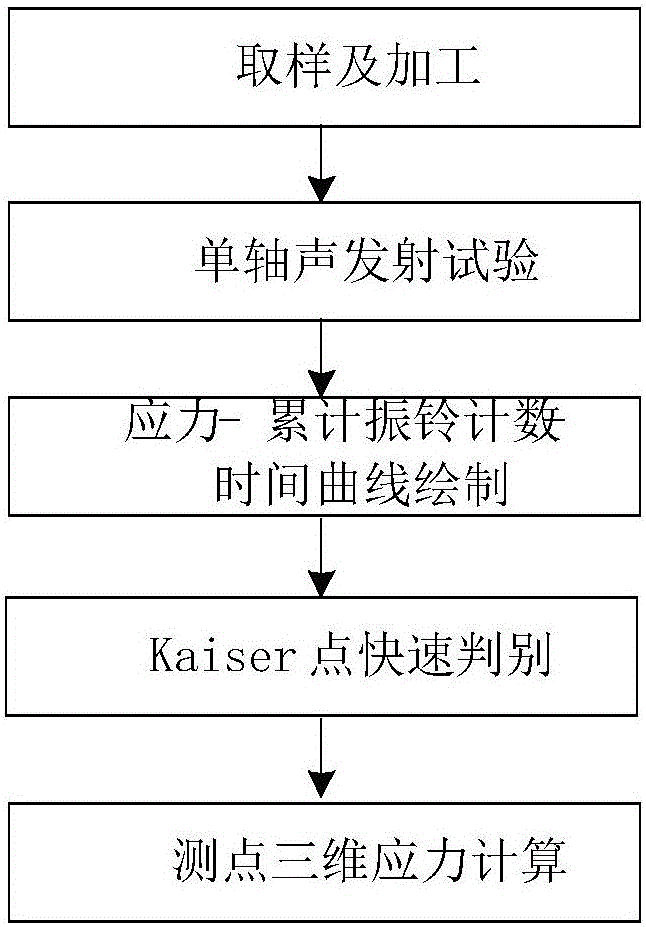

[0075] Such as figure 1 As shown, an acoustic emission method for three-dimensional in-situ stress testing is characterized by the following steps:

[0076] 1) Sampling and processing

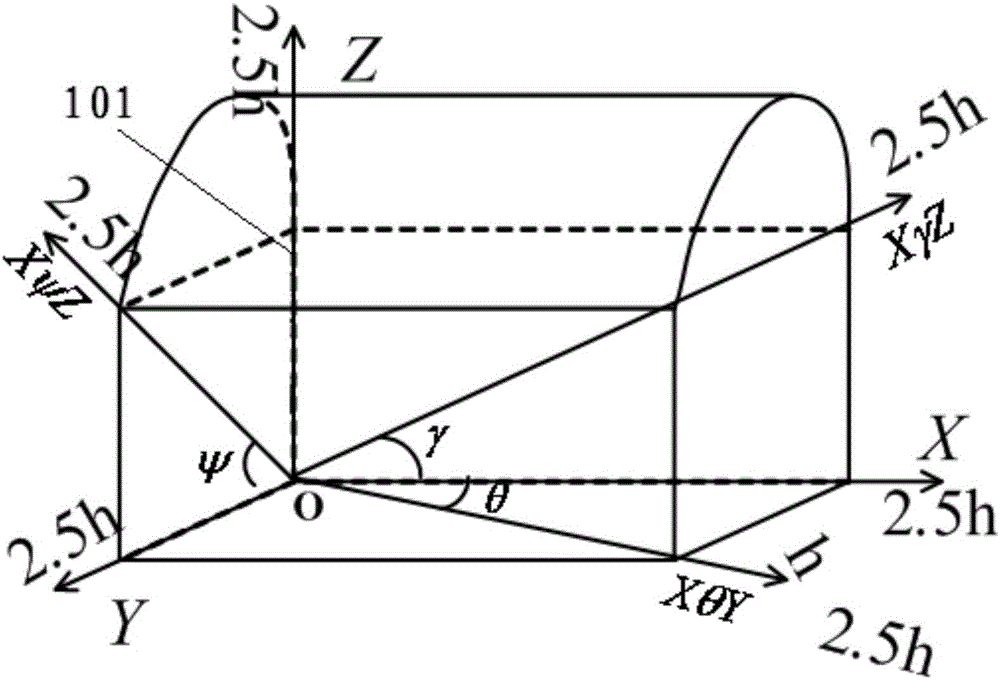

[0077] Establish an oxyz coordinate system near the underground roadway or tunnel face 101, such as figure 2 As shown, the geological compass is used to measure its direction; in the x-direction, y-direction, z-direction, xy-plane, xz-plane, and yz-plane, several cores are drilled into the rock formation; the geological compass is used for each sampling point The direction is measured and recorded.

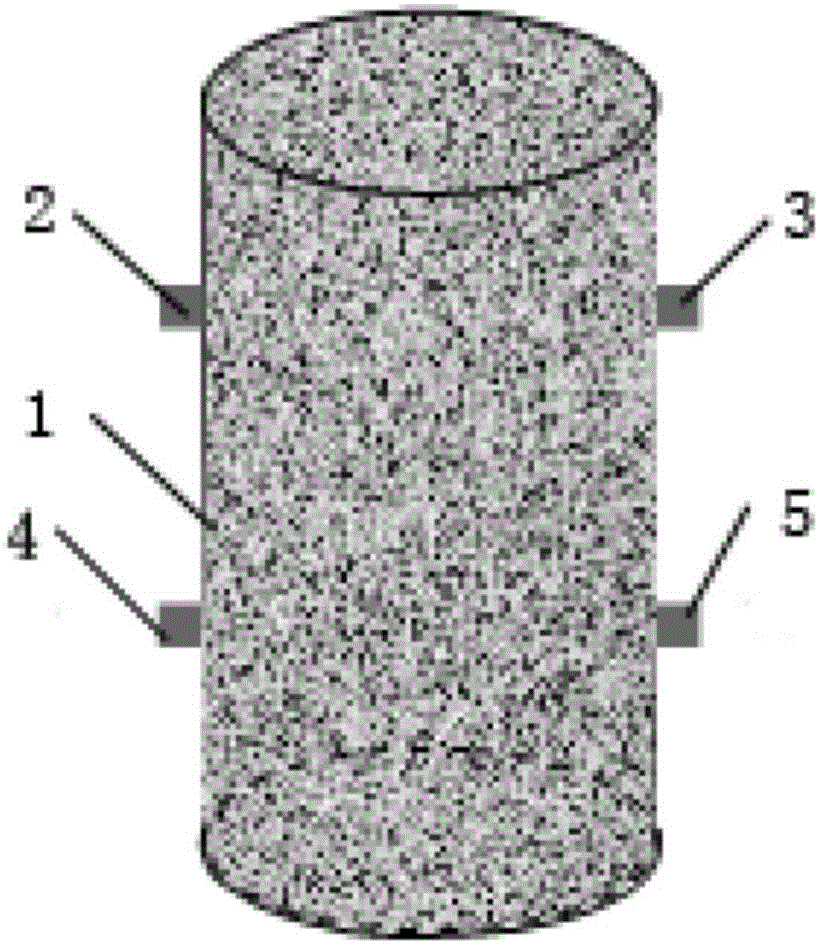

[0078] The sampling depth is required to be more than 2.5 times the width of the roadway or tunnel, the core diameter is at least 50mm, and the length is at least 100mm. Number the direction of the test piece, package it and transport it back to the laboratory, use a rock cutter, end grinder,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com