Stirring, heating and heat preserving device for heat treatment medium cooling speed detection

A technology of heating and heat preservation and temperature measuring device, applied in the field of metal heat treatment, can solve problems that are not conducive to enterprises to correctly select the type of heat treatment medium, formulate accurate and effective monitoring of production processes, cannot guarantee the accurate and reasonable use of heat treatment medium, and the cooling performance of heat treatment medium. Inconsistency and other problems, to achieve stable heat treatment quality, prevent unnecessary losses, and facilitate the use of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

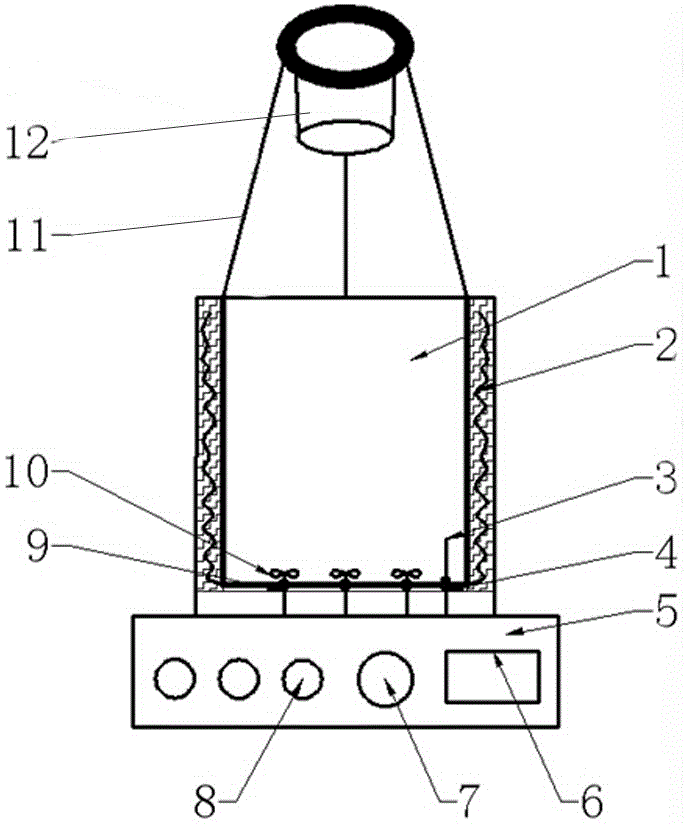

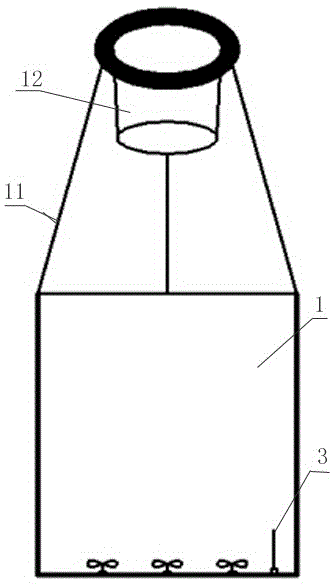

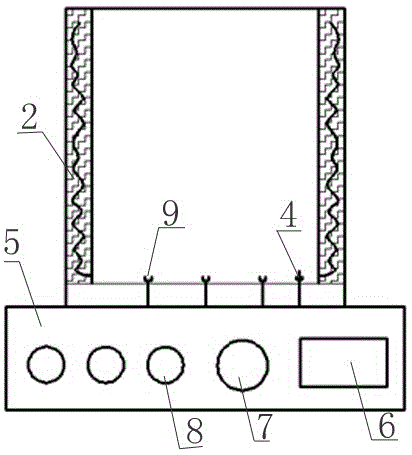

[0023] The present invention as figure 1 shown.

[0024] A heat treatment medium cooling speed detection stirring, heating and heat preservation device, including a heat treatment medium container 1, the heat treatment medium container 1 is erected on the control box, the bottom of the heat treatment medium container 1 is provided with a plurality of spiral stirring devices 10 and a temperature measuring Device 3; Correspondingly, a plurality of spiral stirring device interfaces 9 and a temperature measuring device interface 4 are provided on the base 1 of the control box, and a heating and heat preservation device that cooperates with the outer periphery of the heat treatment medium container 1 is provided on the base of the control box 1 2; The side of the control box 5 is also equipped with a temperature display 6, a heating switch 7, and a stirring switch 8.

[0025] The upper part of the heat treatment medium container 1 is also provided with a bracket 11, and the bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com