Array substrate, preparation method thereof, and touch screen

A technology for array substrates and touch wires, applied in the fields of array substrates and their preparation, and touch screens, can solve problems such as poor touch and display, difficult removal, and increased contact resistance between the common electrode layer 1 and the connection layer 2, so as to avoid touch Control and display poor, reduce the effect of contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

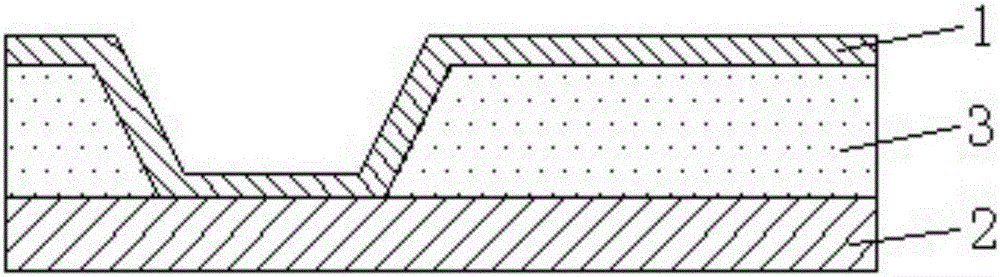

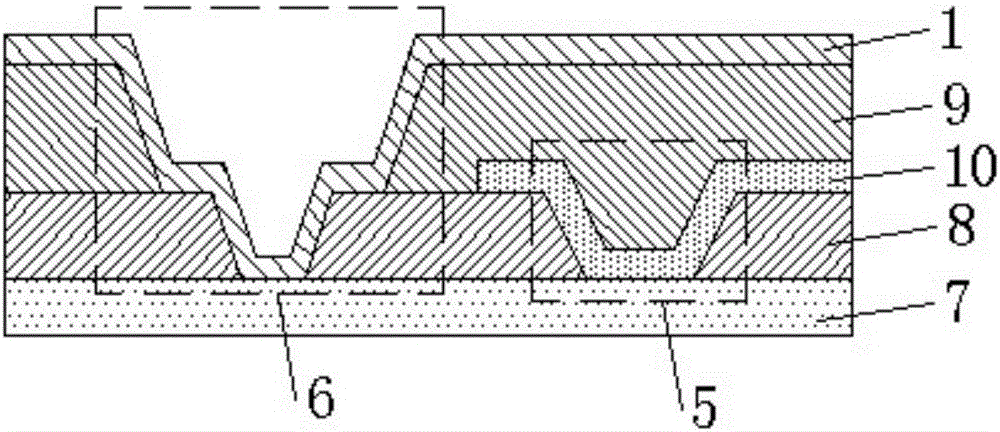

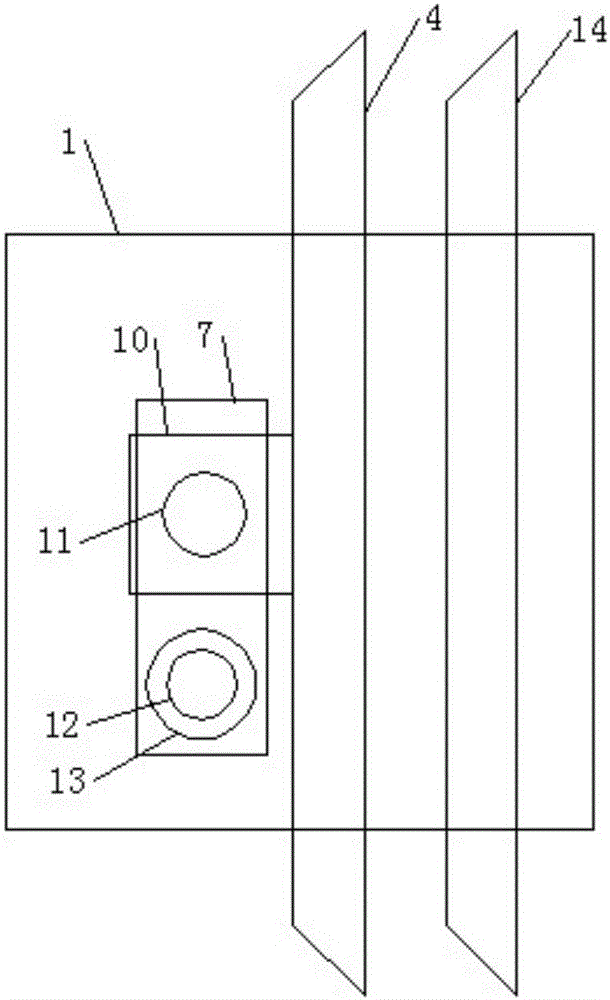

[0038] This embodiment provides an array substrate, figure 2 is a partial cross-sectional view of the array substrate of this embodiment, image 3 It is a perspective view of the partial structure of the array substrate of this embodiment, such as figure 2 , image 3 As shown, the array substrate includes a thin film transistor, a common electrode layer 1 located above the thin film transistor, a touch line 4, and a touch connection terminal 7. The touch connection terminal 7 is arranged in a different layer from the touch line 4 without overlapping. The touch line 4 is connected to the common electrode layer 1 through connection electrodes, wherein the connection electrodes include a first connection electrode 5 and a second connection electrode 6, the touch line 4 is connected to the touch connection terminal 7 through the first connection electrode 5, and the common The electrode layer 1 is connected to the touch connection terminal 7 through the second connection elect...

Embodiment 2

[0046] This embodiment provides a method for preparing an array substrate, which is used to form the array substrate in Embodiment 1. Figure 4 It is a flow chart of the method for preparing the array substrate of this embodiment, as Figure 4 As shown, the method includes the following steps:

[0047] Step S1: forming a figure including a touch connection terminal.

[0048] In this step, it also includes using the same patterning process to form the pattern including the gate on the same layer, that is to say, the pattern of the gate of the thin film transistor and the pattern of the touch connection terminal 7 are formed on the same layer using the same patterning process. In some manufacturing processes of the array substrate, although the touch connection terminal 7 is added in this step, the number of times of the patterning process is not increased. The shape of the touch connection end 7 can be rectangle, circle, ellipse, etc., as long as the touch connection end 7 ha...

Embodiment 3

[0061] This embodiment provides a touch screen, which includes the array substrate in Embodiment 1.

[0062] The touch screen can be specifically a FIC capacitive touch screen, and it can be used in any product or component with display and touch functions, such as liquid crystal display panels, mobile phones, tablet computers, digital cameras, navigators, etc., not only can avoid bad touch and display It appears, and compared with the existing touch screen, it does not increase the number of patterning processes, nor does it increase the manufacturing cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com