Double-layer-board sonic black hole vibration and noise reduction structure

A technology of vibration reduction and noise reduction, double-layer board, applied in the direction of sound-generating equipment, instruments, etc., can solve the problems of not being able to be used as a trap, the influence of black hole effect, and the reduction of structural strength, so as to reduce weight, avoid external features, and improve strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

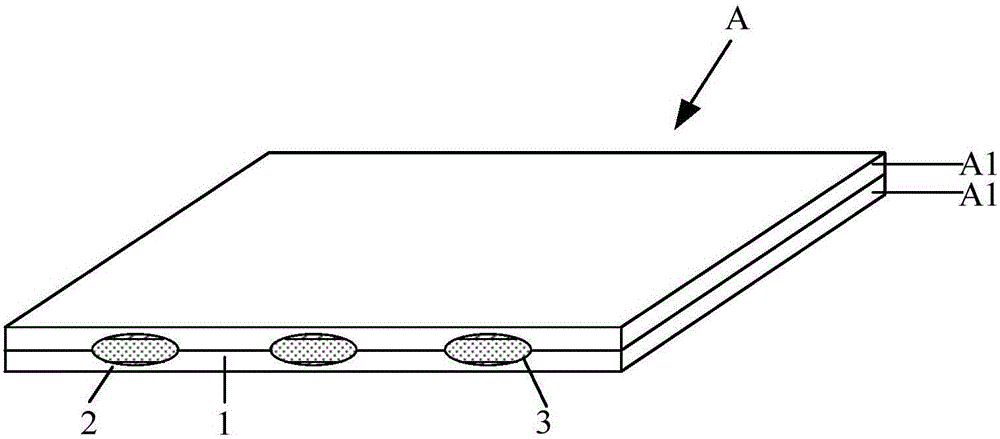

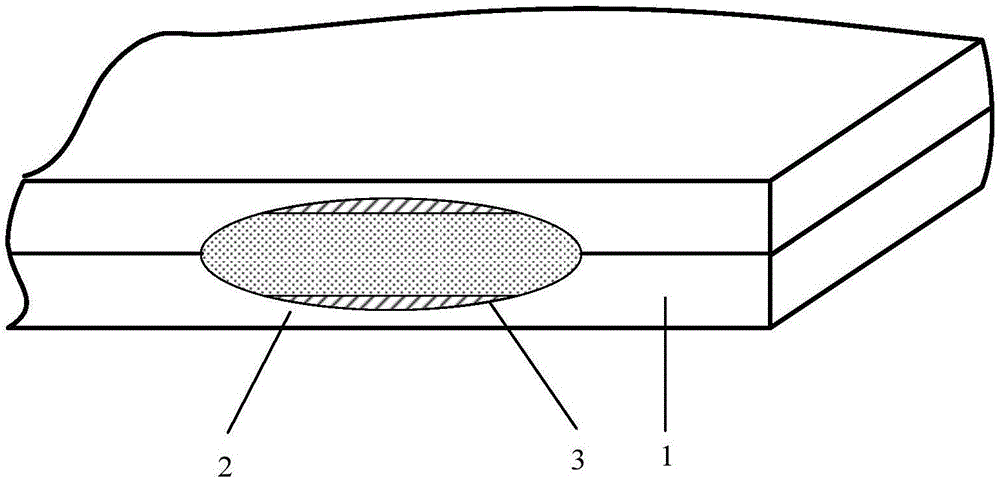

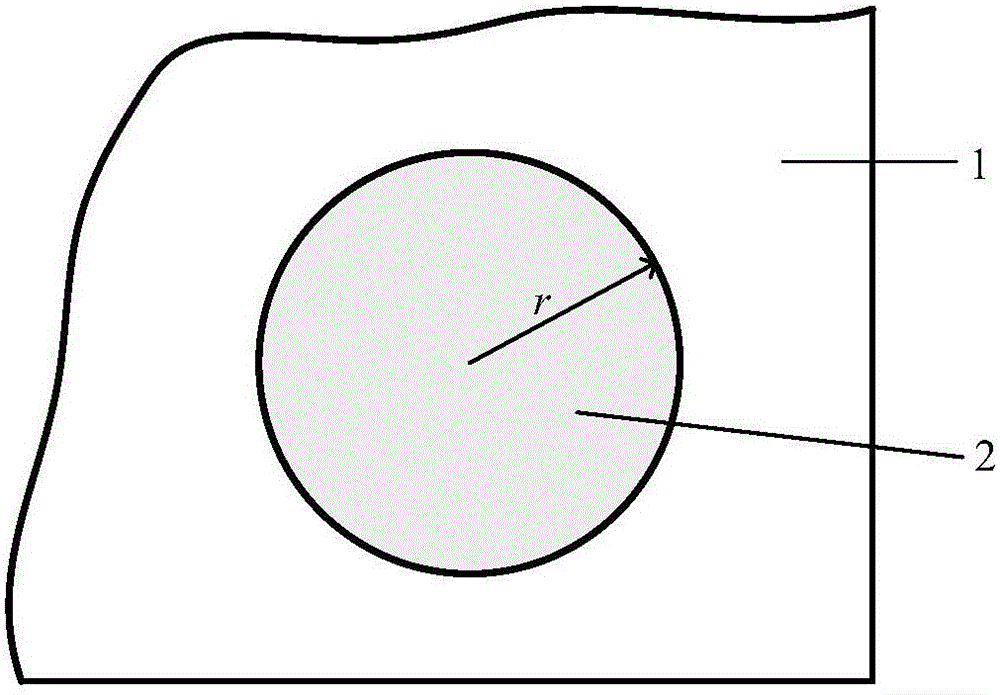

[0026] Please refer to figure 1 and Figure 2A , 2B , 2C, the double-layer plate acoustic black hole vibration and noise reduction structure A of the present invention is formed by combining two plate structures A1, wherein the plate structure A1 includes a uniform area 1 and an acoustic black hole area 2 connected to the uniform area 1, wherein the uniform The distance between the front and rear surfaces of area 1 is constant from right to left, and the distance between the upper and lower surfaces of uniform area 1 is also constant from right to left. The distance between the front and back surfaces of the acoustic black hole region 2 is fixed from right to left, and the distance between the upper and lower surfaces of the acoustic black hole region 2 is from right to left in the form of an exponential function h(x)=ex m (the exponent m is not less than 2) decreases gradually, and the distance between the upper and lower surfaces of the rightmost end of the acoustic black ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com