Universal adapter connector for hot-line work

A technology for live work and conversion joints, which is applied in the field of electric power and can solve the problems of increasing the labor intensity of operators, difficulty in installing work tools, and inability to live replace them.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

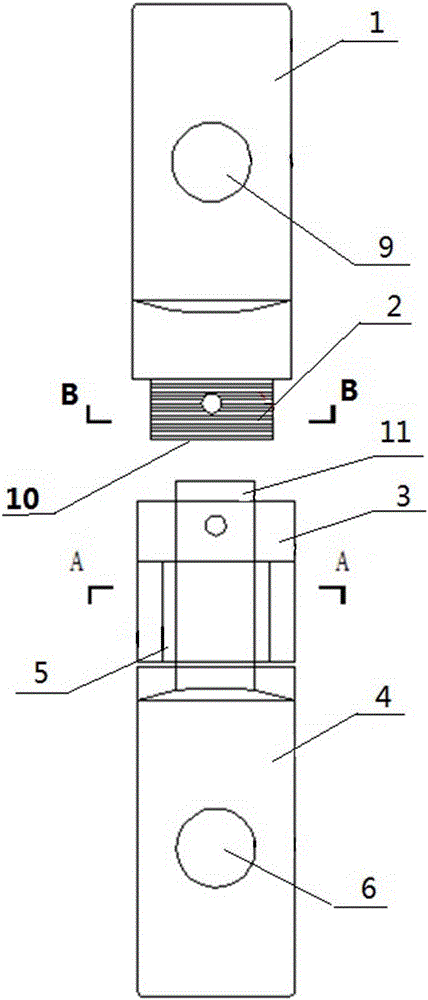

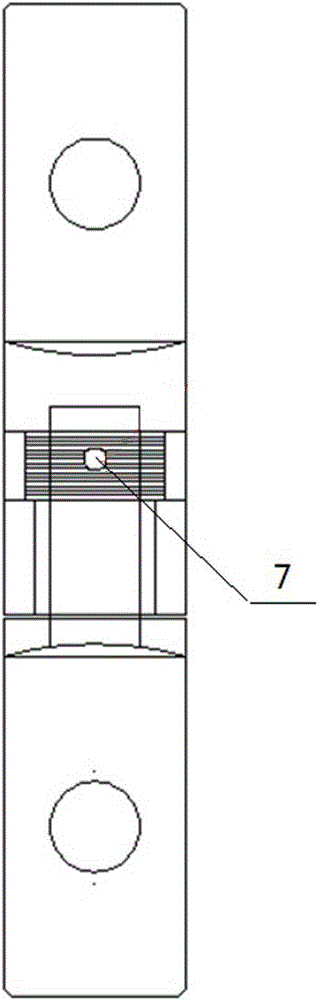

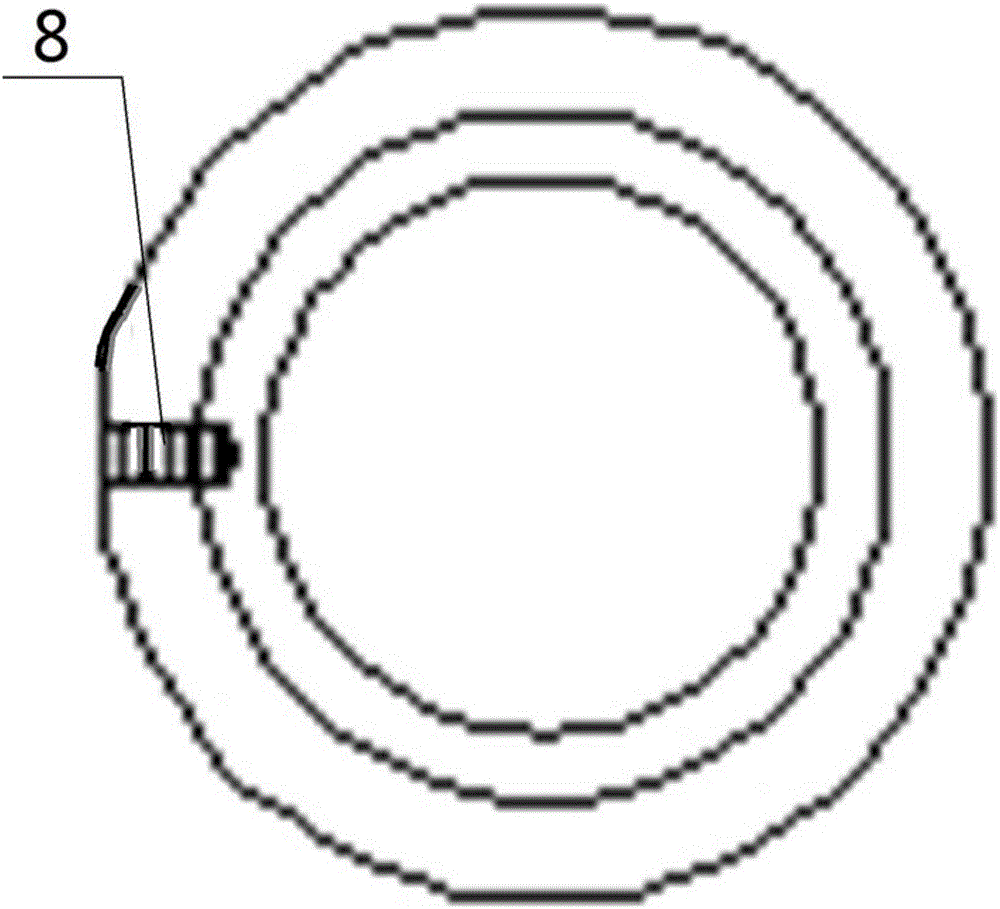

[0014] See figure 1 , figure 2 , image 3 , Figure 4 , a universal conversion joint for live work, the present invention is characterized in that it includes an upper connecting plate 1 and a lower connecting plate 4; between the upper connecting plate and the lower connecting plate, the bolt section 2 of the upper connecting plate and the lower connecting plate pass The upper connected nut section 3 is threaded and connected, and a small screw hole M7 is opened on the bolt section 2, and a small screw hole N7 is opened on the nut section 3, and the bolt section 2 and the nut section 3 are screwed to a certain position to make the small screw hole M7 , The small screw hole N7 forms coincidence; screw the bolt 8 into the small screw hole 7 to prevent loosening during use; the bolt section 2 is provided with a section of inner hole 10;

[0015] An intermediate shaft 11 is provided in the axial direction of the lower connecting plate 4 to pass through the nut segment 3 and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com