Methods for assembling component and product, and product assembling system

An assembly system and component technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems affecting product quality, save installation time and ensure installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

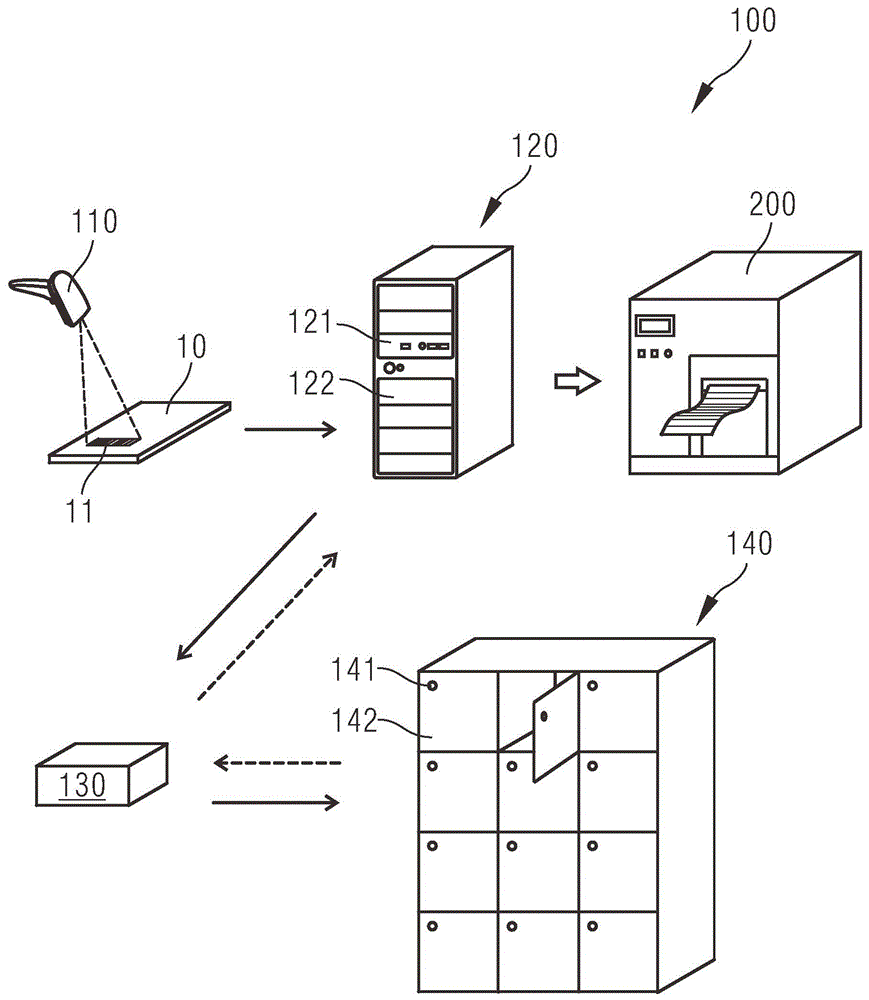

[0018] Since in the error-proof assembly system, the operator is also required to manually select the product being produced according to the order, if the operator selects the wrong product type, the system will guide the operator to take the product corresponding to the selected product type The wrong components are used as production materials, which may affect the quality of the product. Such as figure 1 The assembly system 100 described is used in a production line to assemble a range of products. Operators on the production line will install different products according to the order requirements, so each product has a product model, which corresponds to the type information of the product. When the operator gets an order,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com