Touch control module and manufacturing method thereof, and smartwatch

A technology of a touch module and a manufacturing method, applied in the field of smart watches, can solve the problems of low engineering reliability, reduced pass-through rate, poor durability and firmness of the film layer, etc., so as to improve engineering reliability, simplify manufacturing process, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

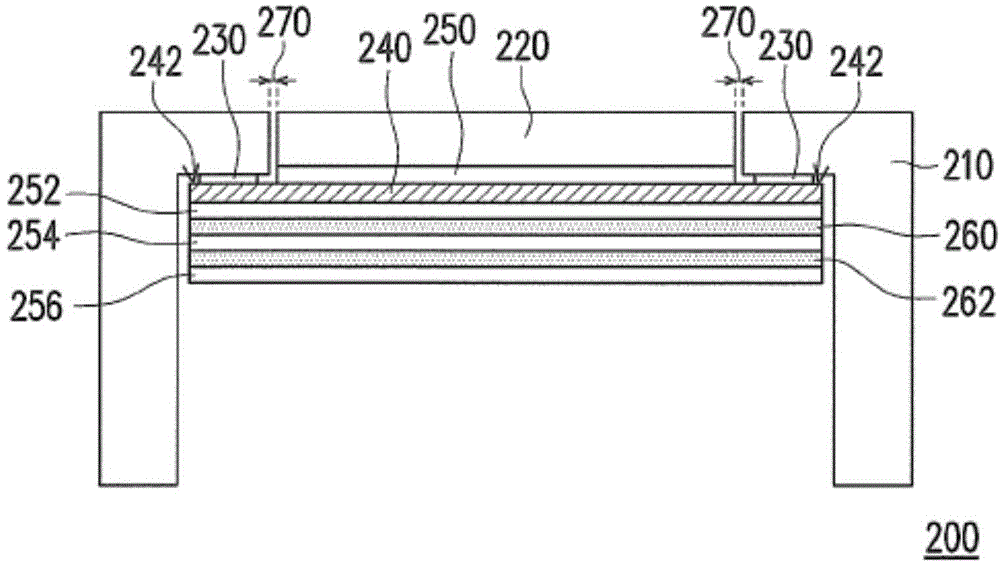

[0059] Figure 4 is a schematic cross-sectional view of a touch module according to an embodiment of the present invention. Please refer to Figure 4 , the touch module 300 includes: a housing 310 , a cover 320 , a connecting element 330 and a touch element 340 . The cover 320 has a main body 322 and a stepped portion 324 around the main body 322 . The thickness d1 of the main body 322 is greater than the thickness d2 of the stepped portion 324 . The connecting element 330 is disposed between the stepped portion 324 and the housing 310 . The touch element 340 is disposed on one side of the cover 320 and located in the casing 310 .

[0060] Possible embodiments of each element will be described below one by one. Please refer to Figure 4For example, the housing 310 may have: a horizontal extending portion 312 and a vertical extending portion 314 , and the connecting element 330 is disposed between the stepped portion 324 and the horizontal extending portion 312 .

[0061]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com