Mineral substance bus duct

A technology of bus duct and minerals, applied in the field of bus duct, can solve problems such as reducing the reliability of refractory bus duct, and achieve the effects of simple structure, easy assembly and good waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

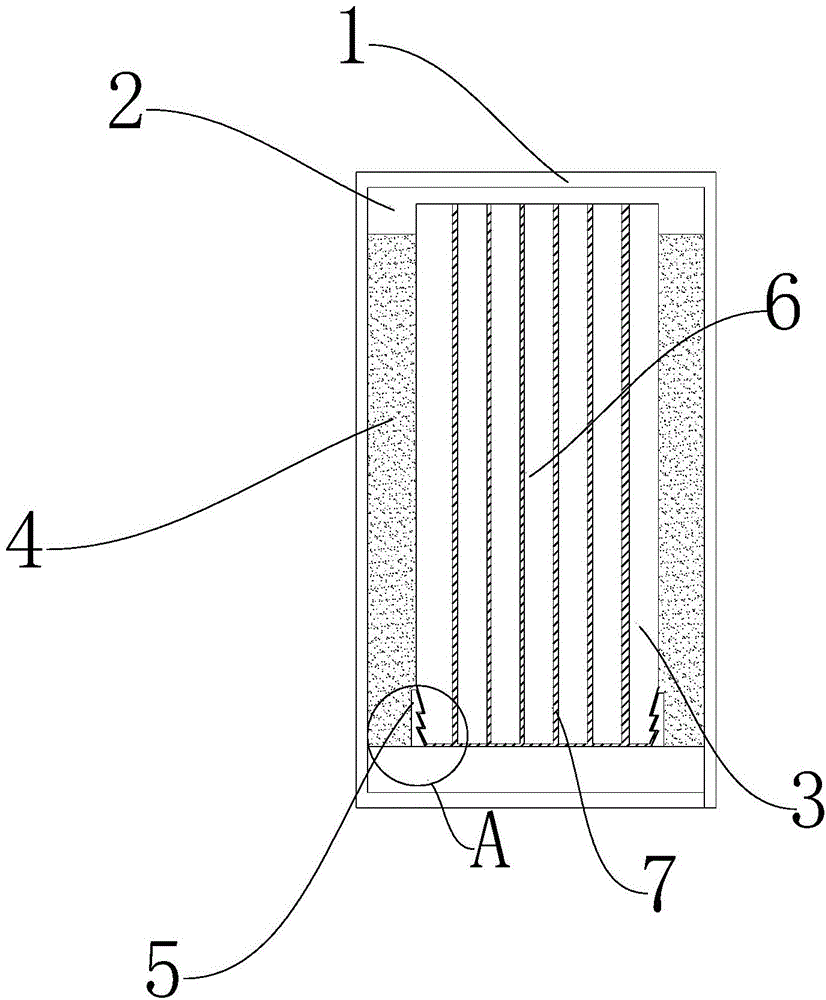

[0012] Combine below Attached picture The present invention is further described with embodiment:

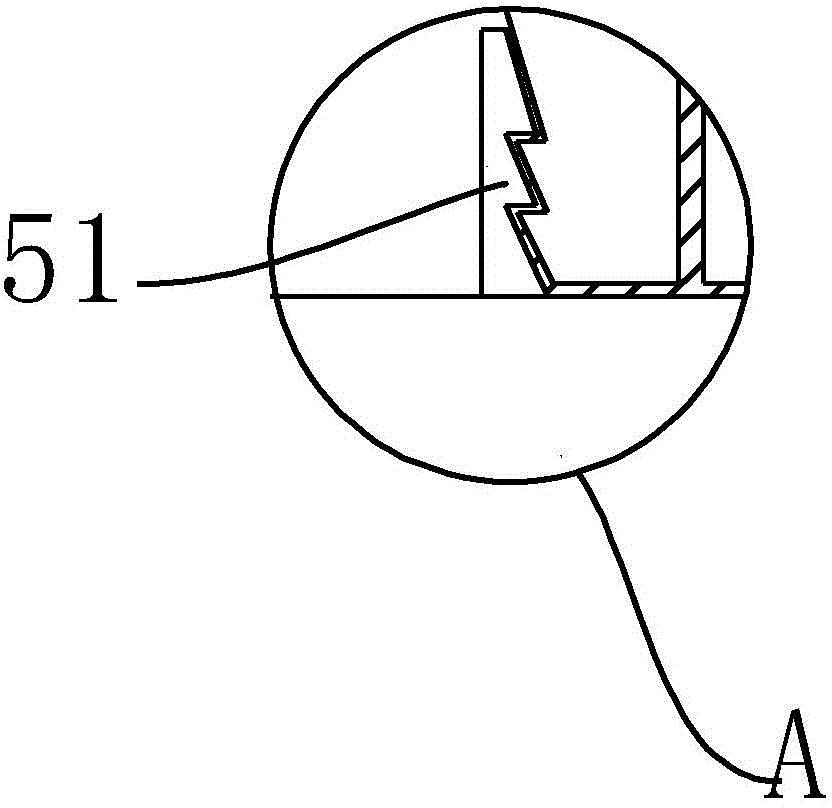

[0013] see picture 1 arrive picture 2 The mineral bus duct shown includes a bus duct main body, and a seamless shell 1 is arranged outside the bus duct main body. The bus duct main body includes a copper bar installation base 7 and a copper bar installation upper seat 2. The copper bar The installation base 7 includes a base plate, and the base plate is provided with copper bar installation grooves formed by several groups of copper sheets 5, and the inner clamping serrations 51 are arranged in the installation grooves, and the inner clamping serrations 51 are provided at the lower end of the copper bars. Matching external clamping saw teeth, the upper seat 2 of the copper bar installation is provided with a slot for installing the upper end of the copper bar, and densely compacted magnesium oxide powder 4 is filled between the copper bars.

[0014] When the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com