Terrain-imitating cutting table for sugarcane harvester

A technology for harvesters and terrain imitation, which is applied to harvesters, harvesters, agricultural machinery and implements, etc., can solve the problems of increasing the load of harvesters, complex structures, and unfavorable promotion, so as to reduce missed harvesting, reduce volume, and ensure The effect of germination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

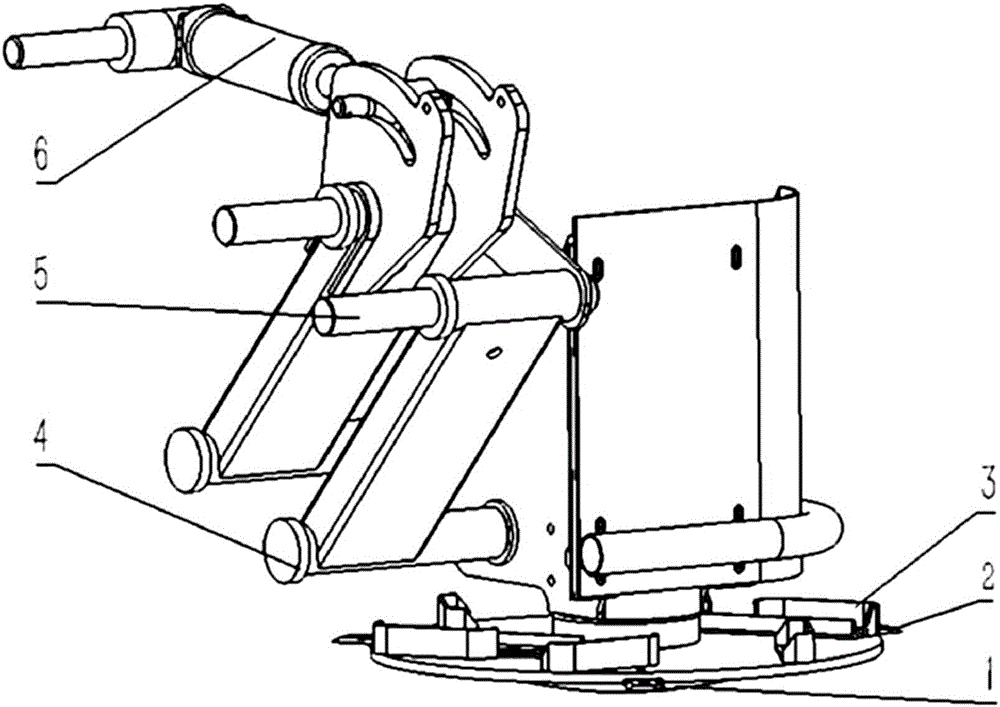

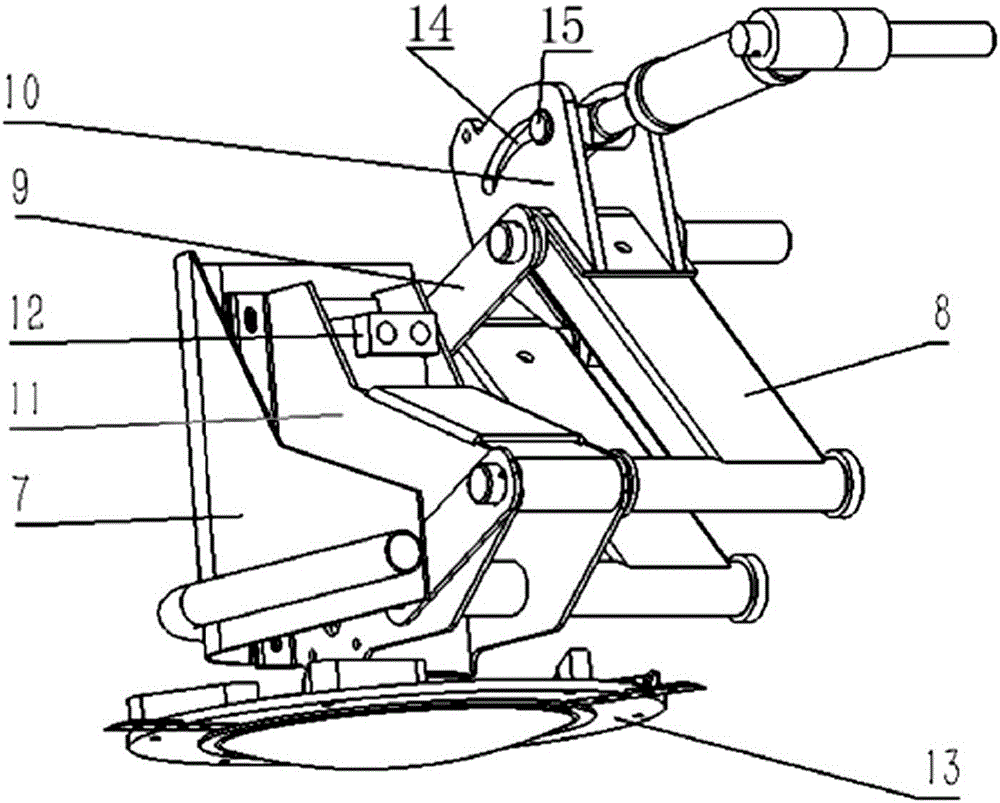

[0027] Such as figure 1 , figure 2 As shown, a terrain-imitating sugarcane harvester header includes a harvester main body and a header assembly. A harvester body is provided with two sets of header assemblies. The header assembly includes a cutting part, a control part and a power unit. part. The power part includes a hydraulic motor 12 and a hydraulic motor base 11, the hydraulic motor 12 is arranged on the hydraulic motor base 11, and the hydraulic motor 12 provides power for the cutting part.

[0028] The cutting part includes a cutterhead 13 and a cutting blade 2. The angle between the cutting part and the horizontal plane is 10°. The cutterhead 13 is installed under the hydraulic motor base 11. The cutterheads 13 on the two sets of header assemblies rotate in opposite directions. The bottom of the cutter head 13 is provided with a hemispherical base 1, and the base 1 is molded by pressing rubber. The cutter head 13 is provided with 6 rectangular sugarcane pickers 3, a...

Embodiment 2

[0032] A terrain-imitating sugarcane harvester header includes a harvester main body and a header assembly. A harvester main body is provided with two sets of header assemblies, and the header assembly includes a cutting part, a control part and a power part. The power part includes a hydraulic motor 12 and a hydraulic motor base 11, the hydraulic motor 12 is arranged on the hydraulic motor base 11, and the hydraulic motor 12 provides power for the cutting part.

[0033] The cutting part includes a cutterhead 13 and a cutting blade 2. The angle between the cutting part and the horizontal plane is 20°. The cutterhead 13 is installed under the hydraulic motor base 11. The cutterheads 13 on the two groups of header assemblies rotate in opposite directions. The bottom of the cutter head 13 is provided with a hemispherical base 1, and the base 1 is formed by pressing plastics. The cutter head 13 is provided with 8 triangular sugarcane pullers 3, and the two ends of the cutting blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com