bubble mask

A bubble mask, the technology of weight percentage, applied in the field of bubble mask, can solve the problems of difficult formulation system, high production cost, and non-permanent bubbles, and achieve the effect of wide industrial application prospect, low production cost, and refreshing skin feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Optimization test of surfactant

[0030] Since the surfactant has a certain irritation to the skin, in this embodiment, the ratio of the surfactant (sodium cocoyl amino acid, olive oil acyl hydrolyzed wheat protein) in the bubble mask formula is first determined.

[0031] The raw material components and amounts of the bubble mask formulation in this embodiment are shown in Table 1.

[0032] Table 1,

[0033]

[0034]

[0035] The preparation process of the bubble mask in this embodiment is as follows:

[0036] 1. Add components 1-4 to the mixing pot and stir evenly;

[0037] 2. Add components 5-6 to the mixing pot and stir evenly;

[0038] 3. Add components 9-11 to the mixing pot and mix evenly;

[0039] 4. Add components 7-8 to the mixing pot and mix evenly;

[0040] 5. The pH is 5.5-6.7, the viscosity is 1200-2000mpa.s, and the material is discharged after qualified.

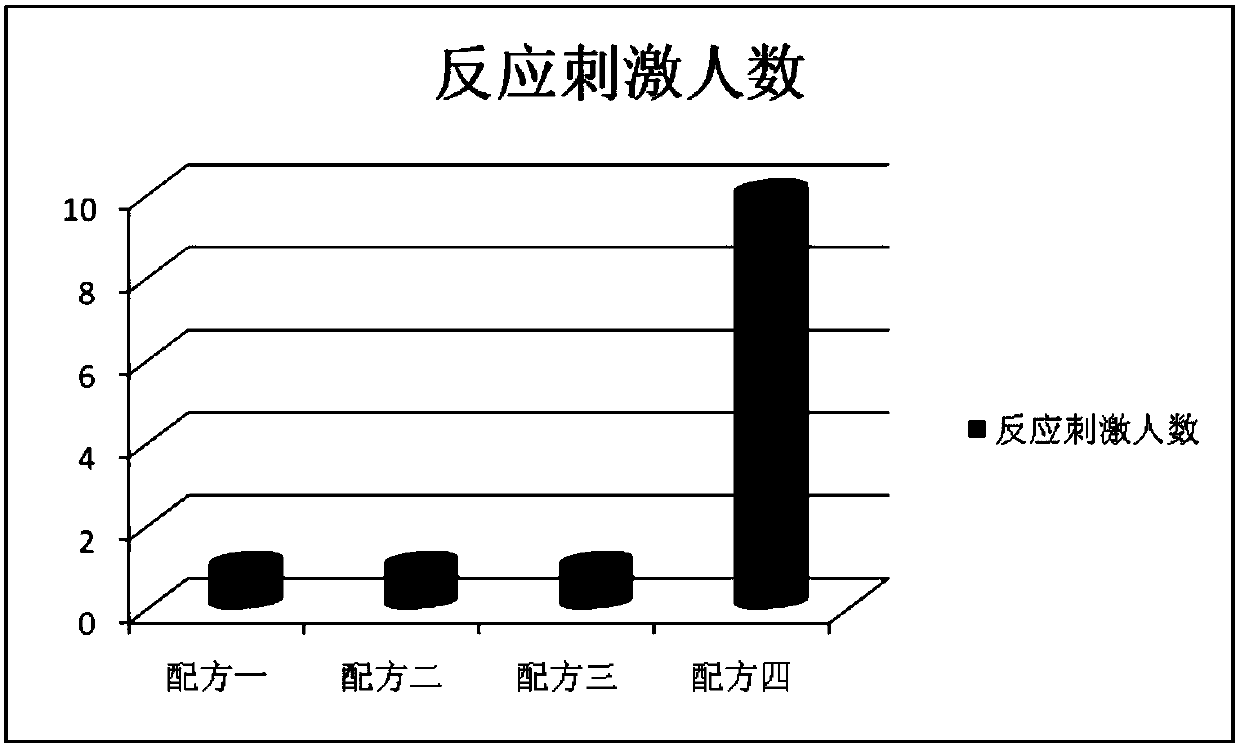

[0041] Fill the formulas of formula 1 to formula 4 shown in Table 1 into finished facial masks, and ask v...

Embodiment 2

[0046] Example 2 Optimization of foaming composition

[0047] In this embodiment, the addition ratio of the foaming ingredients (perfluorobutyl methyl ether, dipolysiloxane) in the bubble mask formula is further determined.

[0048] The raw material components and amounts of the bubble mask formulation in this embodiment are shown in Table 2.

[0049] Table 2,

[0050]

[0051]

[0052] The preparation process of the bubble mask in this embodiment is as follows:

[0053] 1. Add components 1-4 to the mixing pot and stir evenly;

[0054] 2. Add components 5-6 to the mixing pot and stir evenly;

[0055] 3. Add components 9-13 to the mixing pot and mix evenly;

[0056] 4. Add components 7-8 to the mixing pot and mix evenly;

[0057] 5. The pH is 5.5-6.7, the viscosity is 1200-2000mpa.s, and the material is discharged after qualified.

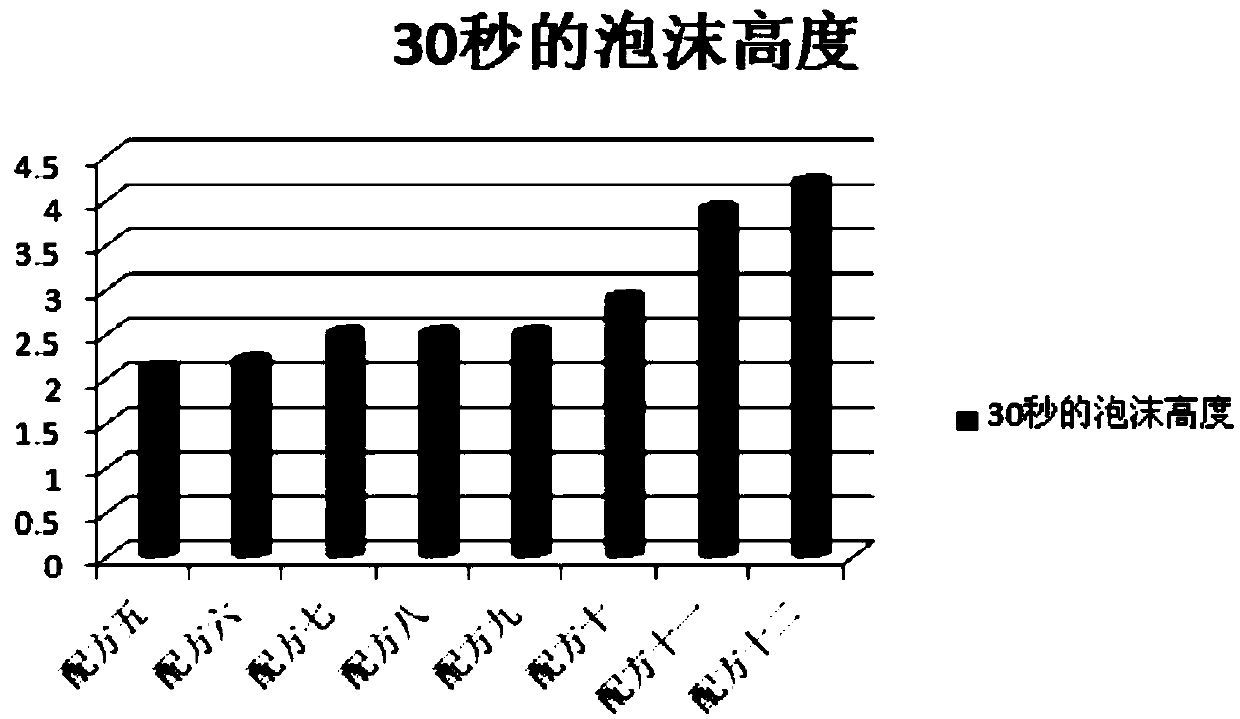

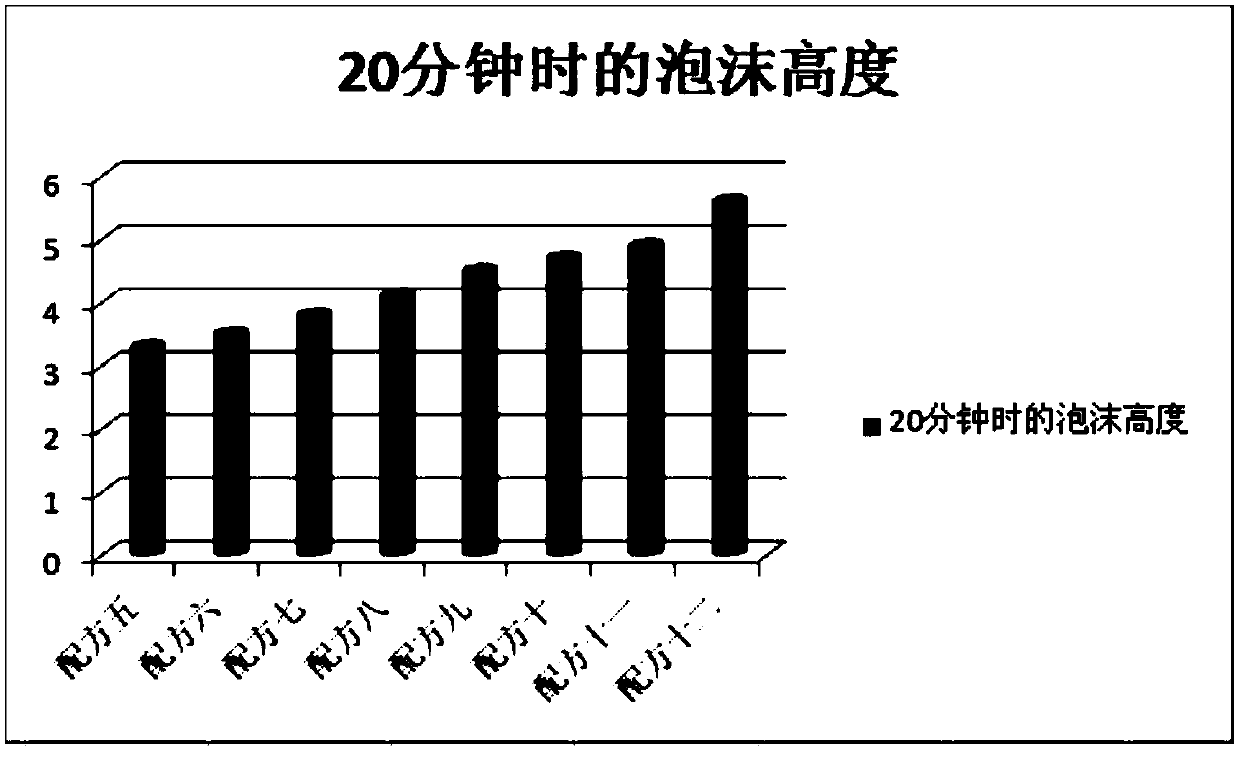

[0058] Fill the formulas of formula 5 to formula 12 shown in Table 2 into a finished facial mask to test the foaming speed and bubble durability. The specific met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com