Cyclone separator

A cyclone separator and flow separation technology, applied in cyclone devices, separation methods, dispersed particle separation, etc., can solve the problems of limited applicable working conditions, limited pressure bearing capacity of devices, and difficulty in ensuring the original separation efficiency, etc. Achieve the effect of eliminating liquid entrainment, eliminating backflow, and not blocking maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

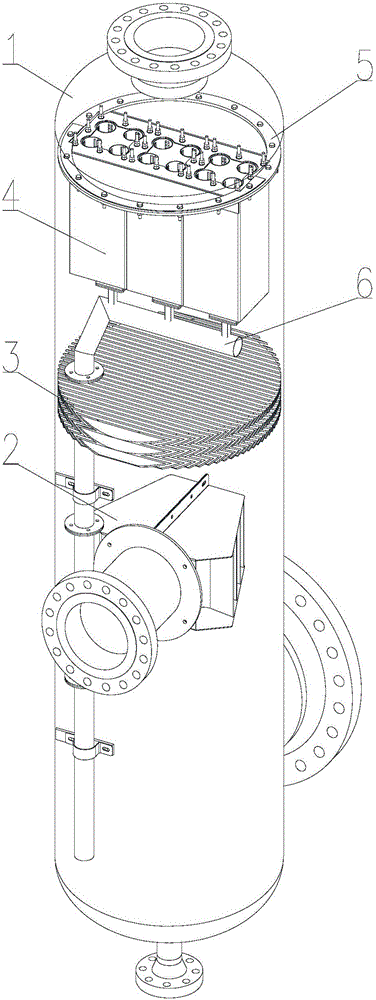

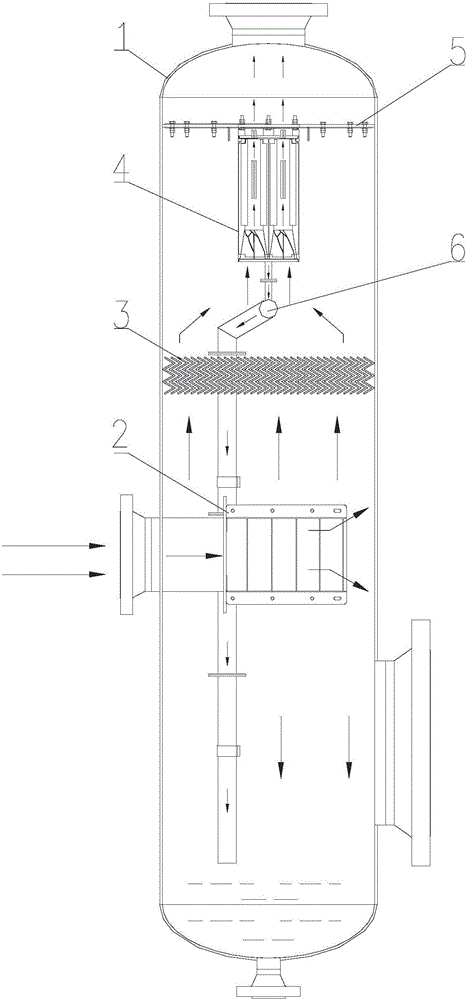

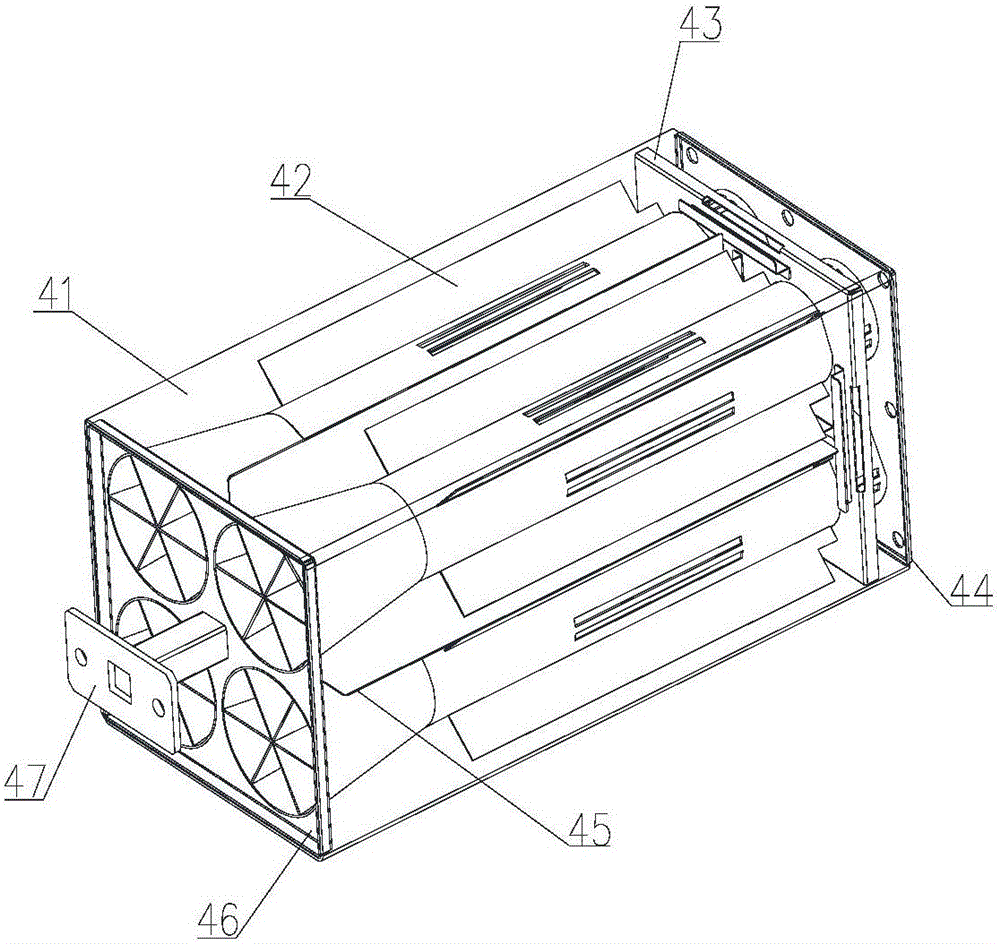

[0017] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as Figure 1-Figure 2 As shown, a cyclone separator includes a container body 1, a blade type inlet pre-separation device 2 is installed at the inlet of the container body, and a blade type or wire mesh structure demister is installed inside the container body 3. The demister is located on the upper part of the vane-type inlet pre-separation device, and the upper part of the demister is equipped with a multi-tube axial flow cyclone separation device 4, and the multi-tube axial flow cyclone separation device can pass The fixing plate 5 is disassembled and fixed inside the main body of the container, and the lower part of the multi-tube axial flow cyclone separation device is connected with a drain pipe 6, and the drain pipe communicates with the demister and extends to the lower part of the main body o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com