Rough rolling rhythm control method

A control method and rough rolling technology, which is applied in the direction of rolling mill control device, metal rolling, metal rolling, etc., can solve the problems of low production line production capacity and slow rolling rhythm, so as to improve the rough rolling rhythm and solve the rolling rhythm slower effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

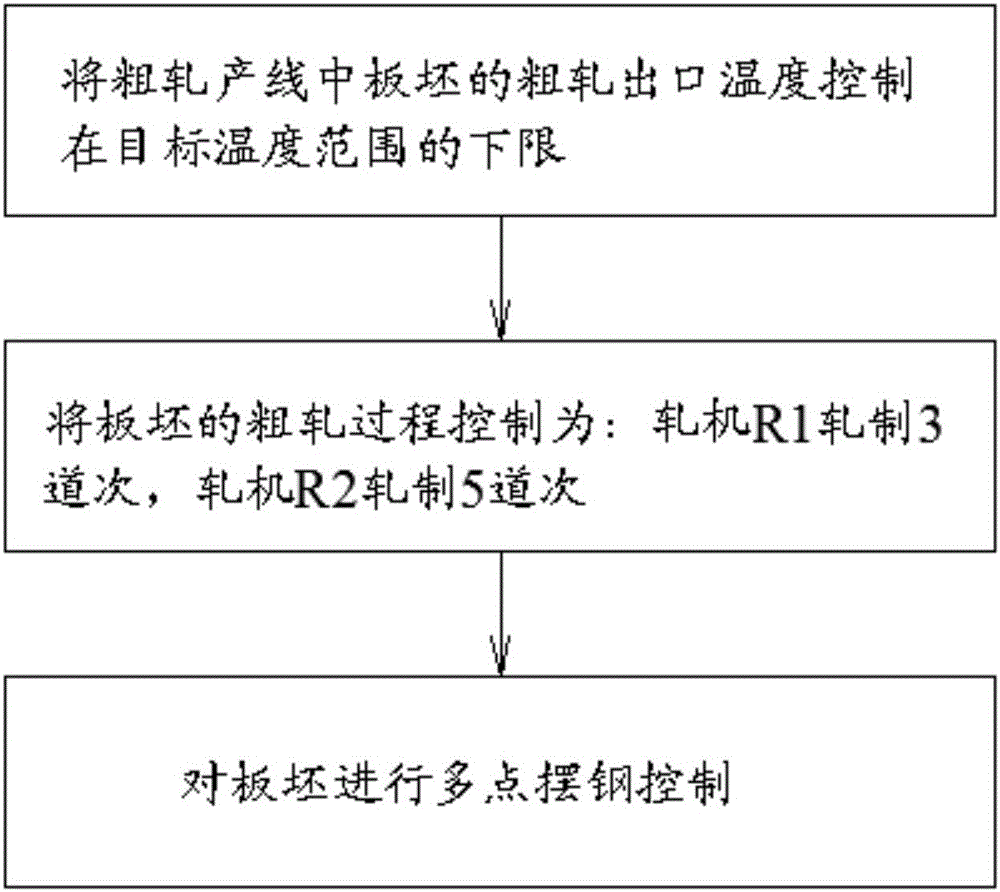

[0043] S1: The target temperature range of the slab in the rough rolling production line is: 880°C-920°C, and the rough rolling exit temperature is 880°C.

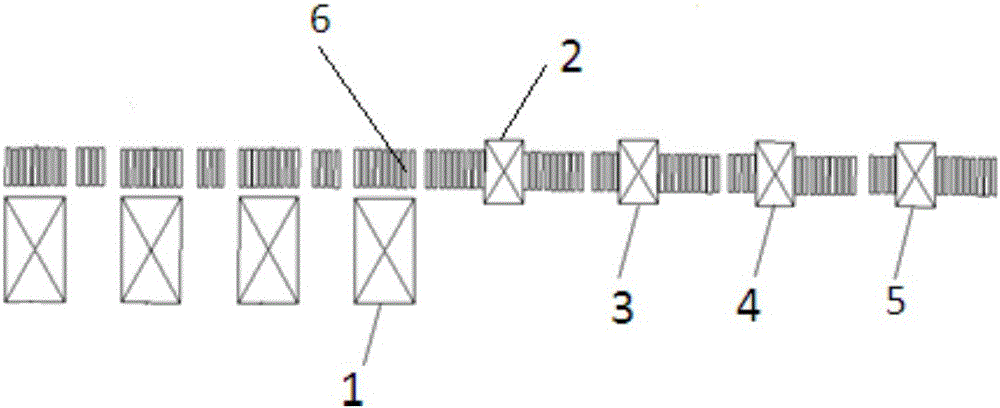

[0044] S2: Control the rough rolling process of the slab as follows: rolling mill R1 rolling 3 passes, rolling mill R2 rolling 5 passes; wherein, the rolling speed of rolling mill R1 is 1.4 m / s; the rolling speed of rolling mill R2 is 2.2 m / s m / s, and the slab is fully descaled during the rolling process of rolling mill R1 and rolling mill R2. In the 2nd, 3rd and 4th passes of the rolling mill R2, the slab is dephosphorized at the entrance and exit of the rolling mill R2.

[0045] S3: Perform multi-point swing steel control on the slab, specifically: S301, swing steel on the first slab at the entrance roller table of rolling mill R2; and control the swing time of the first slab according to the target temperature range. S302. The second slab is placed on the entrance roller table of rolling mill R1; when the first slab st...

Embodiment 2

[0048] S1: The target temperature range of the slab in the rough rolling production line is: 885°C-910°C, and the rough rolling exit temperature is 885°C.

[0049] S2: Control the rough rolling process of the slab as follows: rolling mill R1 rolling 3 passes, rolling mill R2 rolling 5 passes; wherein, the rolling speed of rolling mill R1 is 1.3 m / s; the rolling speed of rolling mill R2 is 2.5 m / s m / s, and the slab is fully descaled during the rolling process of rolling mill R1 and rolling mill R2. In the 2nd, 3rd and 4th passes of the rolling mill R2, the slab is dephosphorized at the entrance and exit of the rolling mill R2.

[0050]S3: Perform multi-point swing steel control on the slab, specifically: S301, swing steel on the first slab at the entrance roller table of rolling mill R2; and control the swing time of the first slab according to the target temperature range. S302. The second slab is placed on the entrance roller table of rolling mill R1; when the first slab sta...

Embodiment 3

[0053] S1: The target temperature range of the slab in the rough rolling production line is: 888°C-915°C, and the rough rolling exit temperature is 888°C.

[0054] S2: Control the rough rolling process of the slab as follows: rolling mill R1 rolling 3 passes, rolling mill R2 rolling 5 passes; wherein, the rolling speed of rolling mill R1 is 1.2 m / s; the rolling speed of rolling mill R2 is 2.8 m / s m / s, and the slab is fully descaled during the rolling process of rolling mill R1 and rolling mill R2. In the 2nd, 3rd and 4th passes of the rolling mill R2, the slab is dephosphorized at the entrance and exit of the rolling mill R2.

[0055] S3: Perform multi-point swing steel control on the slab, specifically: S301, swing steel on the first slab at the entrance roller table of rolling mill R2; and control the swing time of the first slab according to the target temperature range. S302. The second slab is placed on the entrance roller table of rolling mill R1; when the first slab st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com