Sealing and cutting device

A driving device and cutting knife technology, applied in the direction of packaging, transportation packaging, transportation and packaging, etc., can solve the problems of low production capacity, large assembly line area, low production efficiency, etc., to improve production efficiency, reduce the number of manual operations, Ensure consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

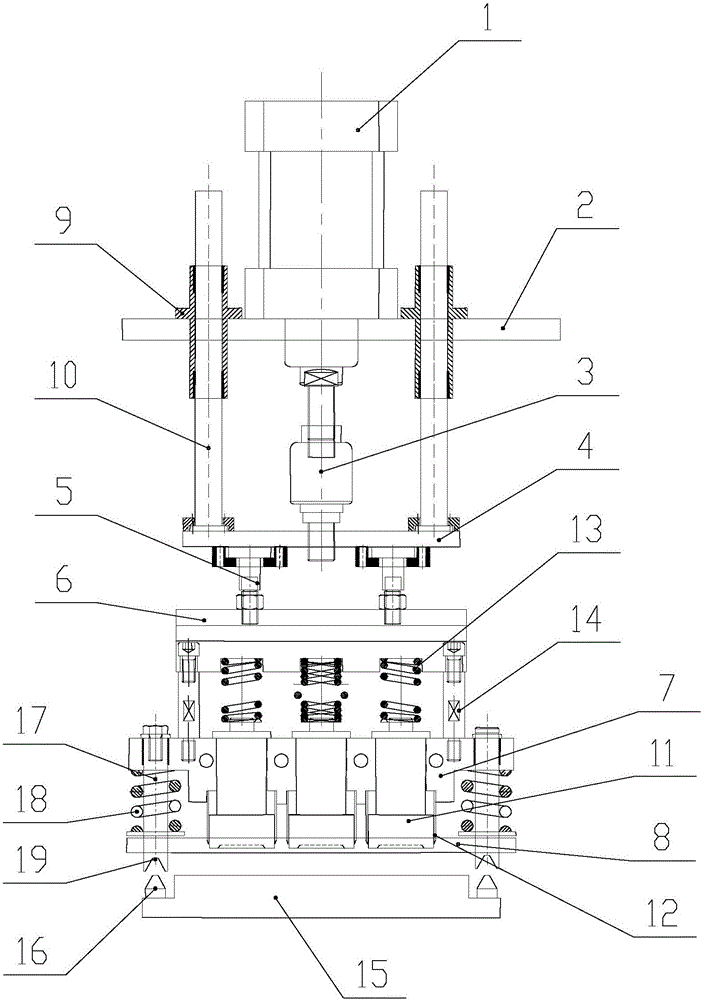

[0015] Such as figure 1 As mentioned above, the present invention discloses a sealing and cutting device, which includes a driving device 1, an upper connecting plate 2, a large floating joint 3, a lower connecting plate 4, a small floating joint 5, a knife seat mounting plate 6, a knife Body 7 and pressing plate 8. Drive device 1 can select air cylinder or driving motor. The driving device 1 provides stable pressure and multi-point positioning functions. Wherein the number of small floating joints 5 is 4, symmetrically distributed between the lower connecting plate 4 and the tool holder mounting plate 6, the upper connecting plate 2 is symmetrically provided with guide sleeves 9, and the lower connecting plate 4 is provided with One-to-one correspondence with the guide sleeve 9, the guide rod 10 that passes through the guide sleeve 9 and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com