Tension quick release device for belt conveyor

A technology of releasing device and belt conveyor, applied in the direction of conveyor, transportation and packaging, which can solve the problems of system impact, large parking acceleration and parking inertia force, equipment damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

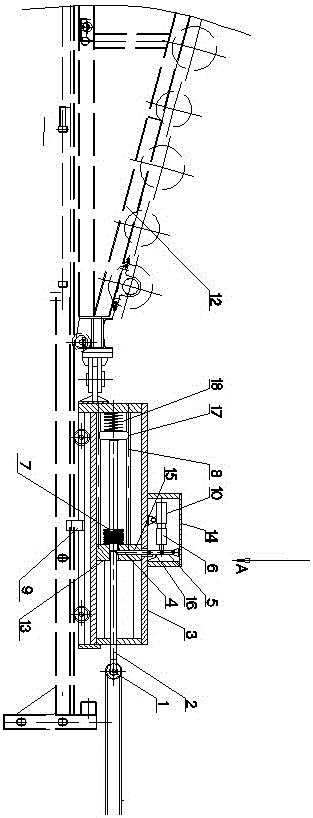

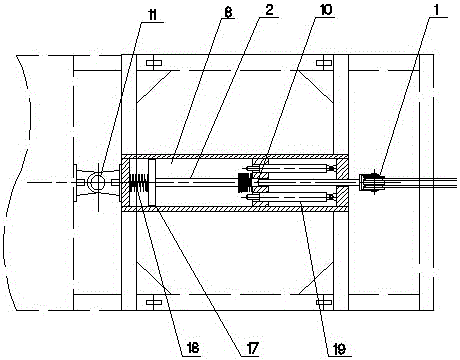

[0011] according to figure 1 , 2 As shown, the present invention relates to a tension quick release device for a belt conveyor, which includes an auxiliary vehicle 3 arranged on the belt conveyor track, the left end of the auxiliary vehicle 3 connects with the tensioning vehicle 12 of the belt conveyor through a pin shaft 11 connected, the auxiliary vehicle 3 is divided into two cavities by a partition 13, the right end of the auxiliary vehicle 3 is provided with a pull rod 2 protruding from the right side wall of the auxiliary vehicle 3, and the right end of the pull rod 2 A pulley block 1 is provided, and the pulley block 1 is rollingly connected with the wire rope of the belt conveyor. A guide rod 8 is fixed in the left cavity of the auxiliary vehicle 3, and the left end of the pull rod 2 passes through the partition plate 13 along the The guide rod 8 slides, and a hole 15 is provided on the partition plate 13 corresponding to the position of the pull rod 2, and a locking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com