Vehicle head bottom frame welding structure

A technology of welding and headstock, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as difficult to remove from the welding mold, welding deformation, size deviation, etc., to prevent welding deformation, improve efficiency, and ensure Effect of weld size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

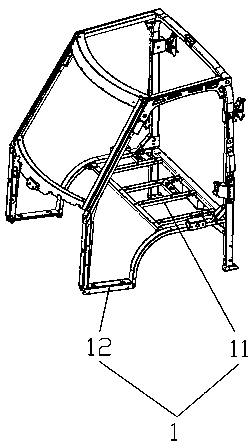

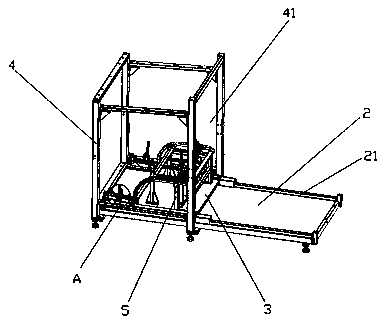

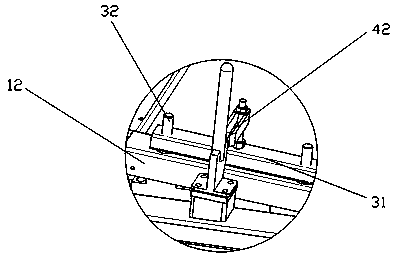

[0022] Such as Figure 1 to Figure 5 As shown in , a welded structure of the front chassis, including

[0023] Base 2, a welded chassis 3 slidably arranged on the base and a welded frame 4 arranged on the base, the welded chassis is provided with a seat bracket placement seat 5, and the welded frame is provided with a seat for the welded chassis to pass through. The entrance and exit door 41 is provided with a welding chamber for accommodating the front of the vehicle in the welding frame, the entrance and exit door is connected with the welding chamber, and the base is provided with a guide rail 21 for welding the chassis to slide, one end of the guide rail is located outside the welding frame, and the other of the guide rail One end extends into the welding cavity through the access door, and the welded chassis can slide in and out of the we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com