An integral hoisting method for a super-long pole tower

An integral hoisting and tower technology, applied in transportation and packaging, load hoisting components, cranes, etc., can solve the problems of bending deformation, deformation and wear, swing of the tower and so on, and achieve the effect of high work efficiency, ensuring safety and not easy to impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0021] An overall hoisting method for a super-long pole tower, comprising the following steps:

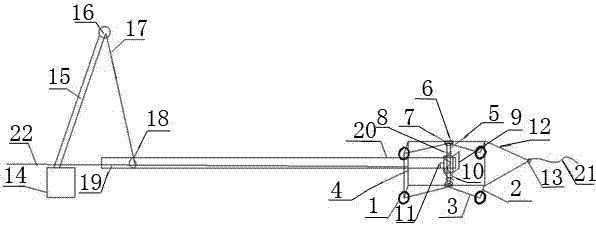

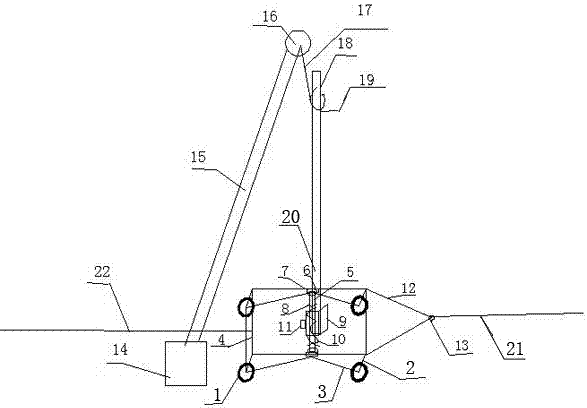

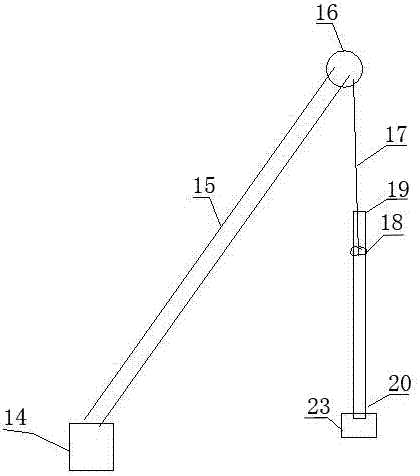

[0022] ① Prepare the four-wheel artillery cart, which includes wheel 1, column 2, diagonal support 3, frame 4, joist 5, bearing 6, clamp 7, hook 8, rear blocking plate 9, wire rope 10, and hand wrench Hoist 11, draw bar 12 and hanging ring 13, described wheel 1 is four, each two at front and back, front axle is provided between front two wheels, rear axle is provided between two wheels behind; There are four, two uprights are symmetrically and vertically arranged at the left and right ends of the front axle, and the other two uprights are symmetrically and vertically arranged at the left and right ends of the rear axle, and the upper ends of the uprights are connected with the vehicle frame; there are four oblique supports 3, Wherein: two oblique su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com