A clamping device for inner wall surface treatment of slender tubular metal parts

A surface treatment and metal-based technology, applied in the field of surface treatment of aircraft parts, can solve the problems of inability to passivate, chemical oxidation, oxide skin cannot be cleaned, and obvious siphon phenomenon in the tube, so as to achieve not easy deformation and convenient clamping of parts , the effect of uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

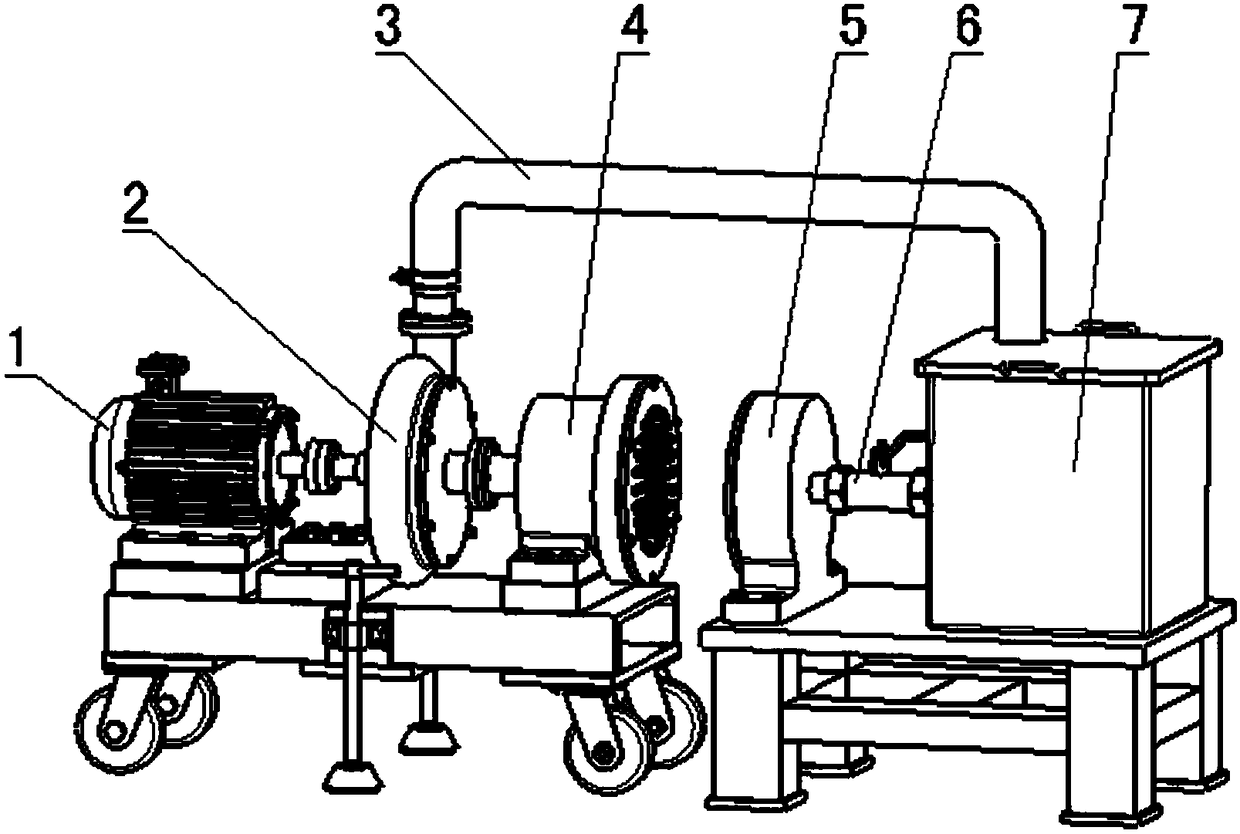

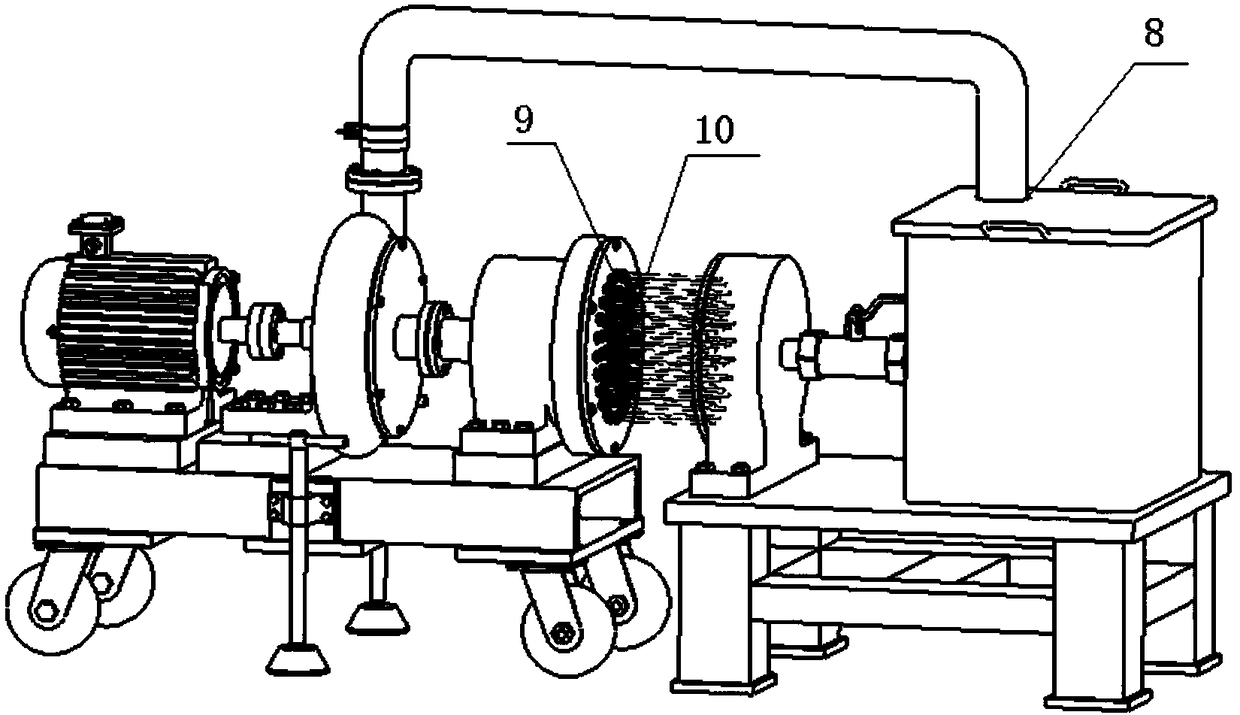

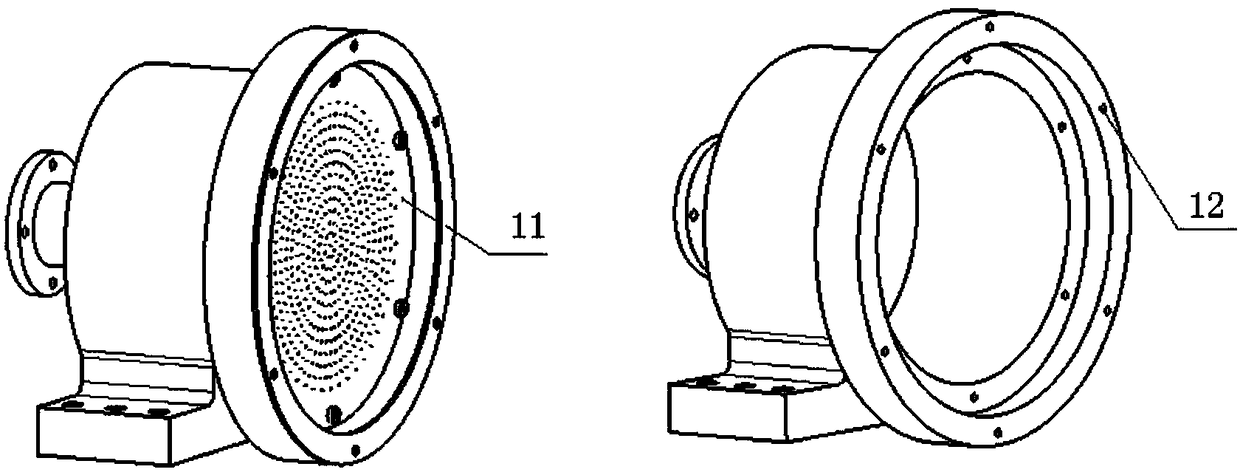

[0010] Such as Figure 1-3 Shown is a clamping device 1 for surface treatment of the inner wall of a slender tubular metal part, including a left chuck 4, a right chuck 5, a hose 3, a solution pump 2, a solution tank 7, a left chuck 4 and The corresponding position of the right clamping disc 5 is provided with a plurality of part clamping holes 12, and each clamping hole 12 is provided with a rubber sealing sleeve 9, and the slender tubular metal parts 10 are clamped between the left clamping disc 4 and the right clamping disc. between the chucks 5, and both ends of the part 10 are inserted into the rubber sealing sleeve 9; the left chuck 4 is connected to the solution pump 2; the right chuck 5 is connected to the solution tank 7 through the solution control valve 6; the top of the solution tank 7 A solution inlet 8 is provided, and a solution outlet is provided on the solution pump 2, and the outlet is connected to the solution inlet 8 by a hose 3; the surface treatment solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com