Indoor testing device for simulating grouting pile end post-grouting and testing method

An indoor test and post-grouting technology, which is applied in the test of foundation structure, construction, foundation structure engineering, etc., can solve the problems of thick sediment at pile ends, lack of theoretical support, and difficulty in hole cleaning, and achieve the effect of convenient excavation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

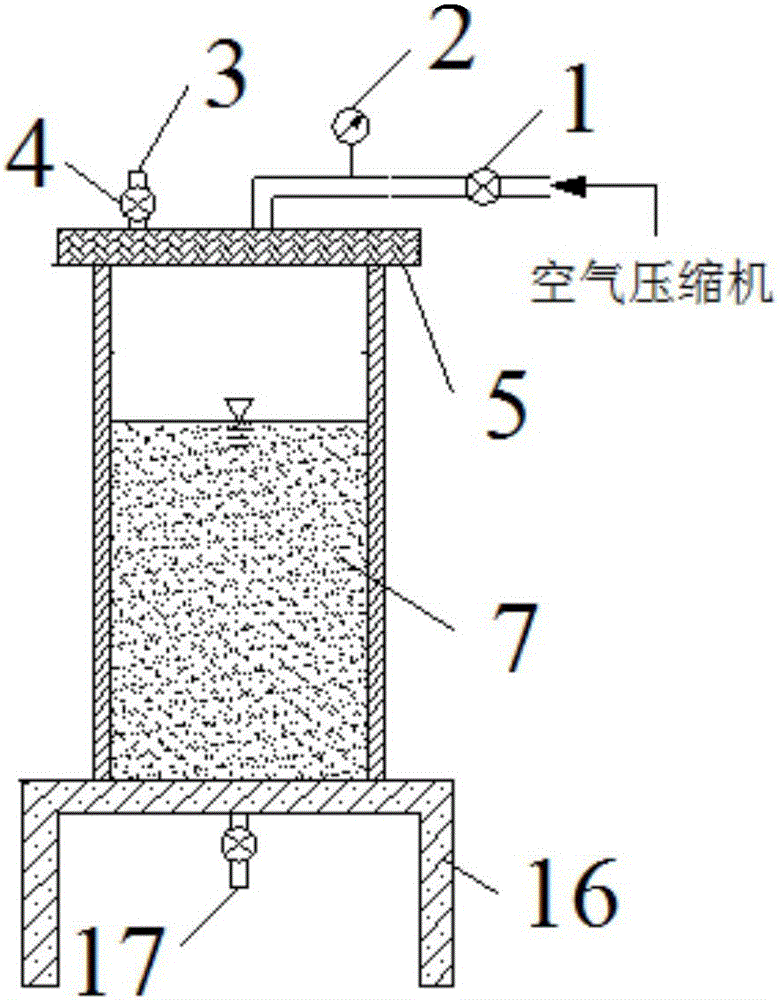

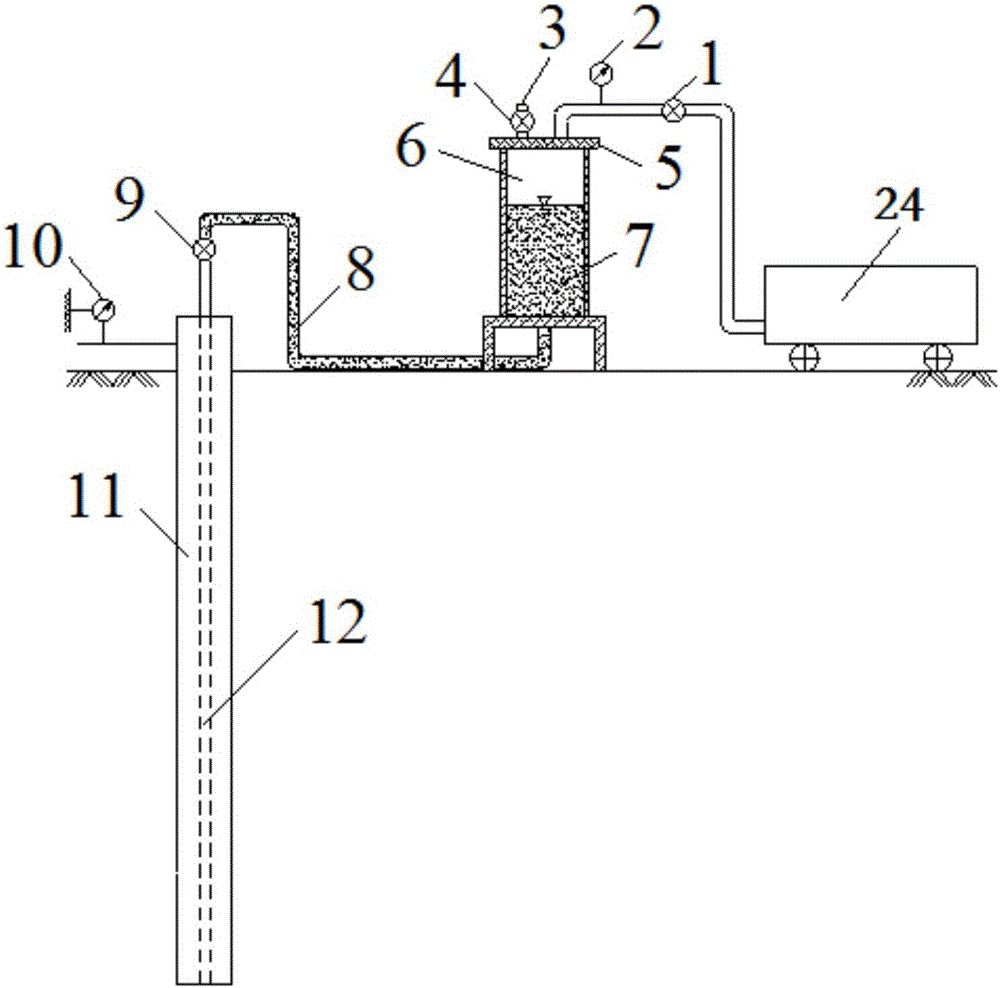

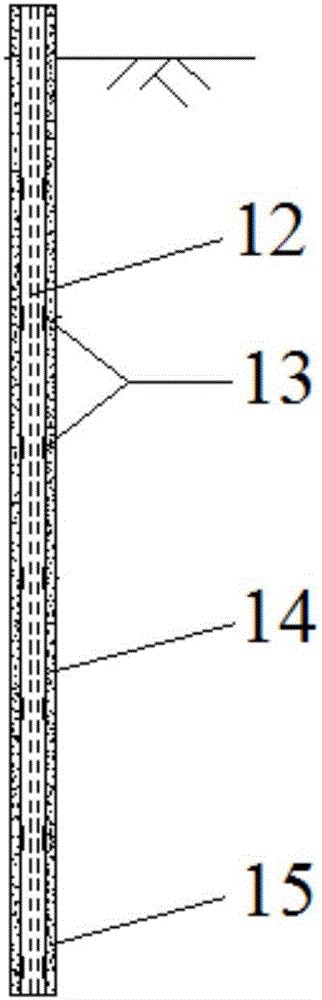

[0043] An indoor test device for simulating post-grouting of cast-in-situ piles, the connection of which is as follows figure 1 As shown, the device includes an air compressor 24, a slurry storage tank 6 and a model pile 11 connected in sequence, and a pressure regulating valve 1 and a pressure gauge 2 are arranged on the connecting pipeline between the air compressor 24 and the slurry storage tank 6, and the slurry storage tank The top of 6 is provided with flange top cover 5, and above flange top cover 5 is provided with pressure relief valve 4, and this pressure relief valve 4 communicates with atmosphere through pressure relief hole 3. Cement slurry is placed inside the grout storage tank 6, and the bottom of the grout storage tank 6 is connected to the model pile 11 through the grout inlet pipe 8 and the grouting valve 9. The grouting pipe 12 is inserted in the middle of the model pile, and a hundred Subtable 10 is mainly used to test the lifting displacement of the model...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com