Excavating tool for a tunnel boring machine and boring machine comprising such tool

A technology for tunnel boring machines and tools, applied in tunnels, slitting machinery, mining equipment, etc., can solve the problems of complicated movements, lost screws and nuts, etc., and achieve the effect of convenient installation and disassembly operations and easy automatic application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

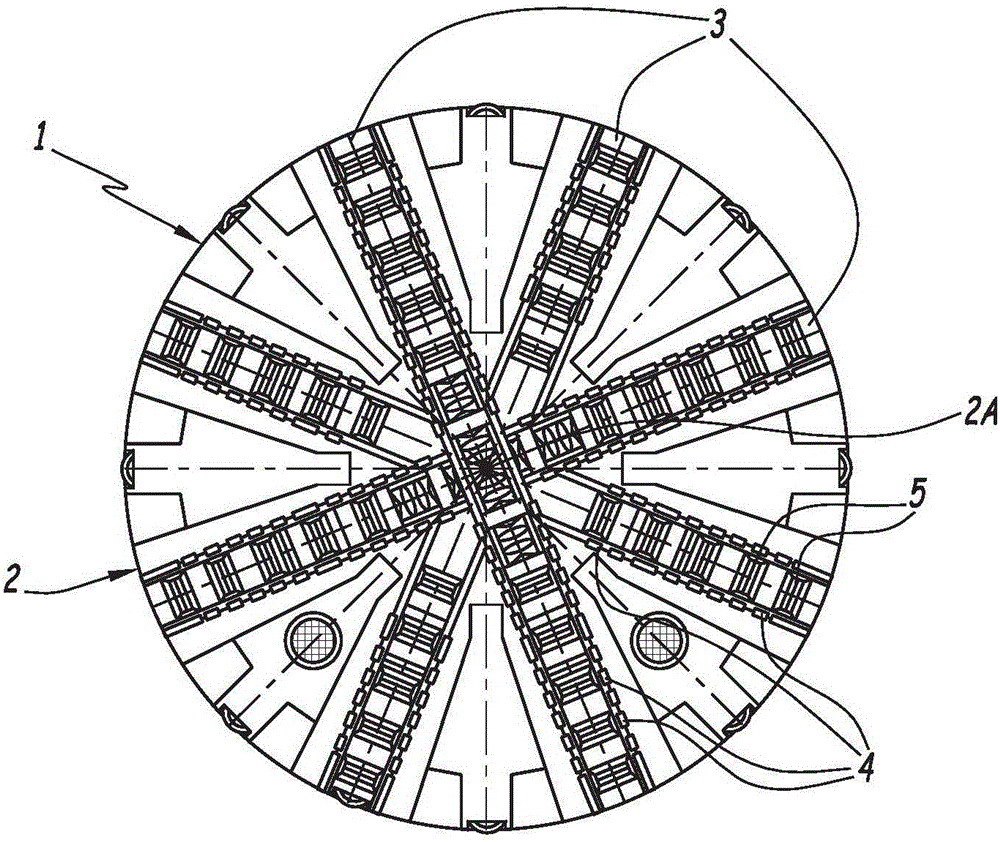

[0040] exist figure 1 shows schematically a tunnel boring machine 1 for which a tubular housing with a substantially circular base comprises a front shield comprising a cutting head 2 at its front, the The cutting head 2 is in contact with the cutting face excavated by the full-face tunnel boring machine. In a manner known per se, the cutting head 2 , sometimes referred to as the boring head, is designed so as to be driven in rotation about an axis 2A which substantially corresponds to the central longitudinal axis of the tubular casing of the full-face tunnel boring machine 1 . exist figure 1 Here, the full-face tunnel boring machine 1 is viewed from the front and on the axis 2A, so that only its cutting head 2 is visible, the rest of the full-face tunnel boring machine extends towards the rear and on the axial extension of the head.

[0041] As explained in the introductory part of this text, the tunnel boring machine 1 excavates the ground by cutting it off under the act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com