An oil-hydraulic buoyancy adjustment system and method

A buoyancy adjustment and hydraulic technology, applied in the direction of fluid pressure actuators, etc., can solve the problems of unutilized deep sea pressure, high pump working pressure, complex system structure, etc., to solve the bottleneck of miniaturization and deep diving technology, and improve work Efficiency, the effect of reducing pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

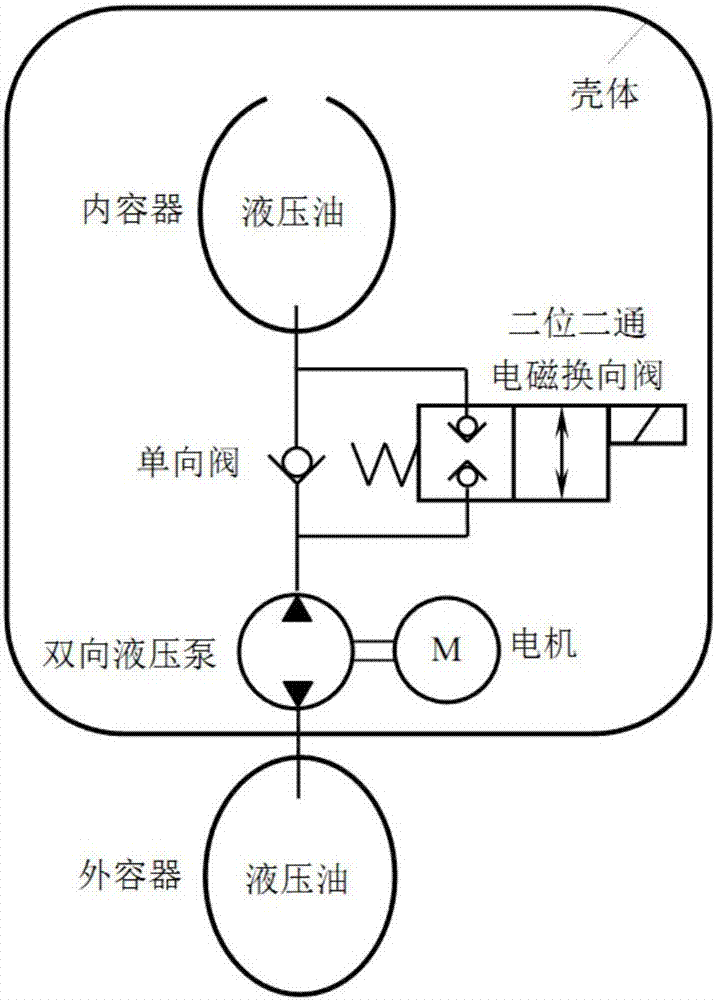

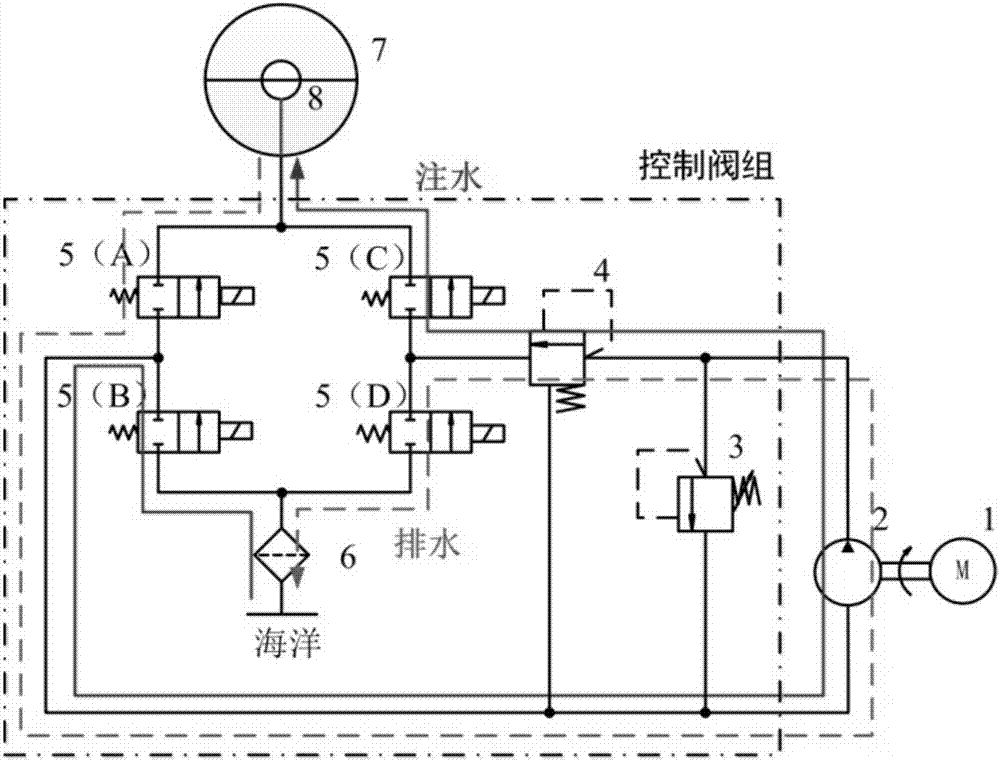

[0026] Example 1, such as Figure 4 As shown, this embodiment discloses an oil-hydraulic buoyancy adjustment system. The system includes a housing 41 filled with an inert gas of a certain pressure; an outer container 42 containing hydraulic oil is arranged outside the housing 41 The housing 41 is provided with an inner container 43 containing hydraulic oil, a two-position two-way electromagnetic reversing valve 44 and a two-way hydraulic pump-motor 45. The volume of the outer container 42 and inner container 43 can be changed with the change of the internal hydraulic oil. The elastic oil bag, and the inner container 43 and the outer container 42 are connected through the above-mentioned two-position two-way electromagnetic reversing valve 44 and the two-way hydraulic pump-motor 45 so as to transmit hydraulic oil between each other; the housing 41 A motor-generator 46 connected to the two-way hydraulic pump-motor 45 is also provided, a control system 47 for controlling the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com