Experiment device and method for measuring Young modulus of metal wire according to simple harmonic vibration

A technology of simple harmonic vibration and Young's modulus, applied in the direction of applying repetitive force/pulsation force to test the strength of materials, etc., can solve problems such as data error, inaccurate tension, and difficult adjustment of telescopes, and achieve enhanced problem-solving capabilities Ability, observation and measurement convenience, and the effect of cultivating innovative spirit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

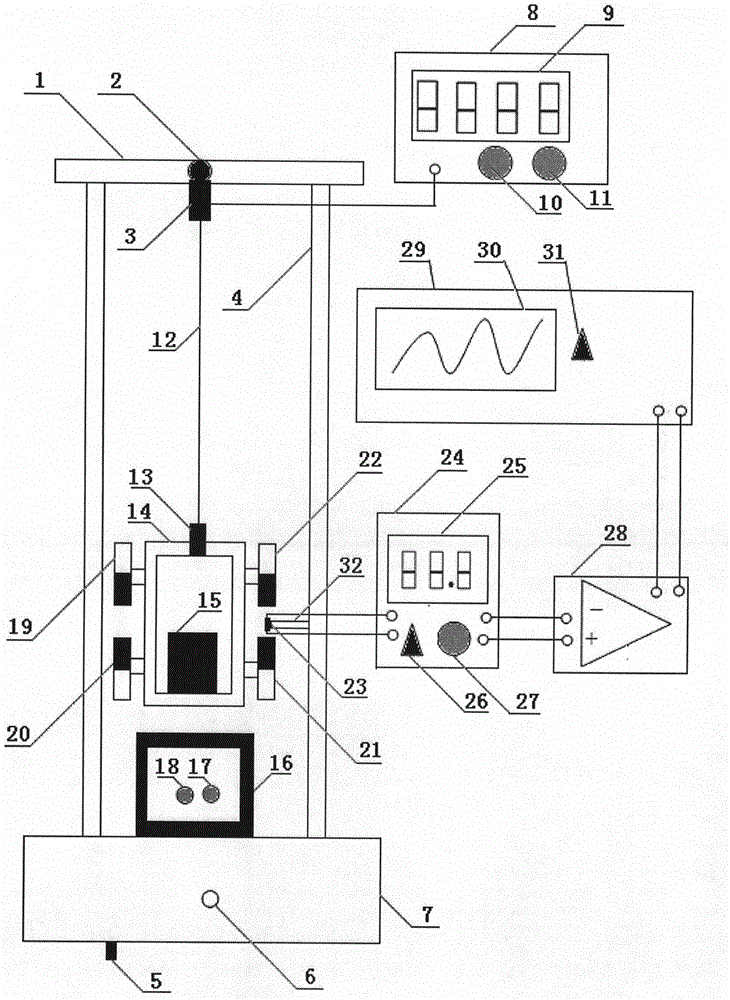

[0039] In the figure, a support 4 is set on the support base 7, a crossbeam 1 is arranged at the upper end of the support 4, an upper chuck 2 and a force-sensitive sensor 3 are arranged in the middle of the crossbeam 1, and one end of the metal wire 12 is connected with the upper chuck 2 and the force-sensitive sensor 3. One end links to each other with the lower clamp 13, and the lower clamp 13 is fixed with a metal frame 14, and an iron block 15 is fixed inside the metal frame 14, and an electromagnet device 16 is arranged below the metal frame 14. The force-sensitive sensor 3 is connected with the force-sensitive sensor measurement controller 8 through an interface, and the force-sensitive sensor 3 is used to measure the tensile force of the metal wire 12 , and can be displayed through the force-sensitive sensor measurement display screen 9 . The electromagnet device 16 is used to apply a pulling force to the metal wire 12 by acting on the iron block 15 through magnetic forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com