Ceramic glaze prepared from waste concrete powder and preparation method of ceramic glaze

A technology for waste concrete and ceramic glaze, which is applied to the field of ceramic glaze prepared from waste concrete powder and its preparation, can solve the problems of less reuse, occupy a large amount of land, soil and air pollution, etc., and achieves increased added value and cost. Low, reduced number of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The specific implementation steps are as follows:

[0032] (1) Mix 5g feldspar powder, 2.5g quartz powder, 0.5g kaolin powder, 5g glaze fruit powder, 2.5g waste concrete powder and glass powder 1:1 mixture, 2g talcum powder and 0.5g zinc oxide powder, and stir well .

[0033] (2) Heat the mixture in step (1) to 1160° C. in a heating furnace and keep it for 60 min.

[0034] (3) Then, the temperature is lowered and cooled in a heating furnace.

[0035] (4) Detect basic properties such as whiteness, Mohs hardness and water absorption of the prepared ceramic glaze.

[0036] The ceramic glaze prepared according to the present invention is compared with the ceramic glaze prepared by the original formula. The formulas of the examples are compared with the original formula as shown in Table 1, and the comparison of basic properties is shown in Table 2.

[0037] Table 1 Formula comparison

[0038] components

Kaolin

glaze fruit

wol...

Embodiment 2

[0044] The specific implementation steps are as follows:

[0045] (1) Mix 5g feldspar powder, 2.5g quartz powder, 0.5g kaolin powder, 5g glaze fruit powder, 2.5g waste concrete powder and glass powder 0.5:1 mixture, 2g talc powder and 0.5g zinc oxide powder, stir well .

[0046] (2) Heat the mixture in step (1) to 1200° C. in a heating furnace and keep it for 60 min.

[0047] (3) Then, the temperature is lowered and cooled in a heating furnace.

[0048] (4) Detect basic properties such as whiteness, Mohs hardness and water absorption of the prepared ceramic glaze.

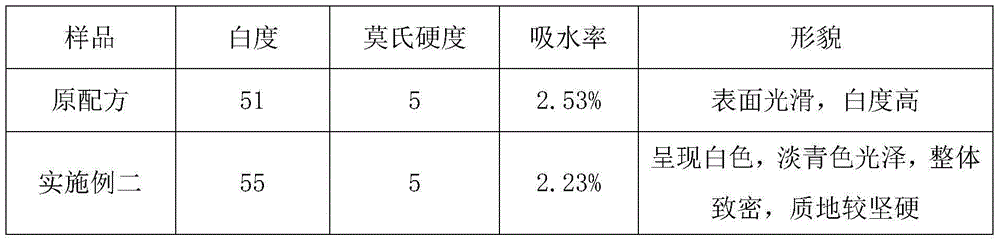

[0049] The ceramic glaze prepared according to the present invention is compared with the ceramic glaze prepared by the original formula. The comparison of the example formula and the original formula is shown in Table 3, and the comparison of basic properties is shown in Table 4.

[0050] Table 3 formula comparison

[0051] components

quartz

Kaolin

glaze fruit

wollastonite...

Embodiment 3

[0056] Example 3: Waste concrete powder mixture (waste concrete: glass powder = 1:1.5) replaces wollastonite

[0057] The specific implementation steps are as follows:

[0058] (1) Mix 5g feldspar powder, 2.5g quartz powder, 0.5g kaolin powder, 5g glaze fruit powder, 2.5g waste concrete powder and glass powder 1:1.5 mixture, 2g talc powder and 0.5g zinc oxide powder, stir well .

[0059] (2) Heat the mixture in step (1) to 1200° C. in a heating furnace and keep it for 100 min.

[0060] (3) Then, the temperature is lowered and cooled in a heating furnace.

[0061] (4) Detect basic properties such as whiteness, Mohs hardness and water absorption of the prepared ceramic glaze.

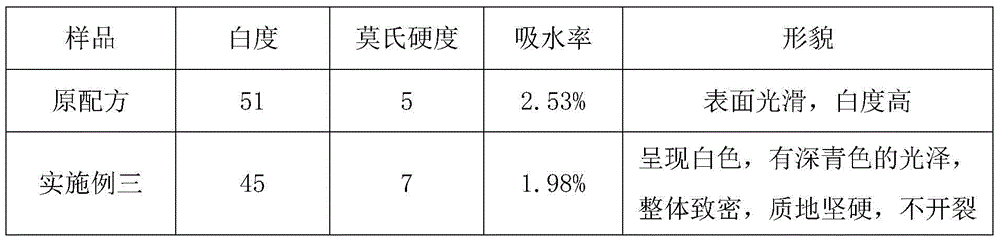

[0062] The ceramic glaze prepared according to the present invention is compared with the ceramic glaze prepared by the original formula. The comparison of the example formula and the original formula is shown in Table 5, and the comparison of basic properties is shown in Table 6.

[0063] Table 5 for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com