Control system and control method of medium and deep hole trolley

A technology of control system and control method, applied in general control system, control/regulation system, program control in sequence/logic controller, etc., can solve the problems of easy wear, harsh working environment, loud noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

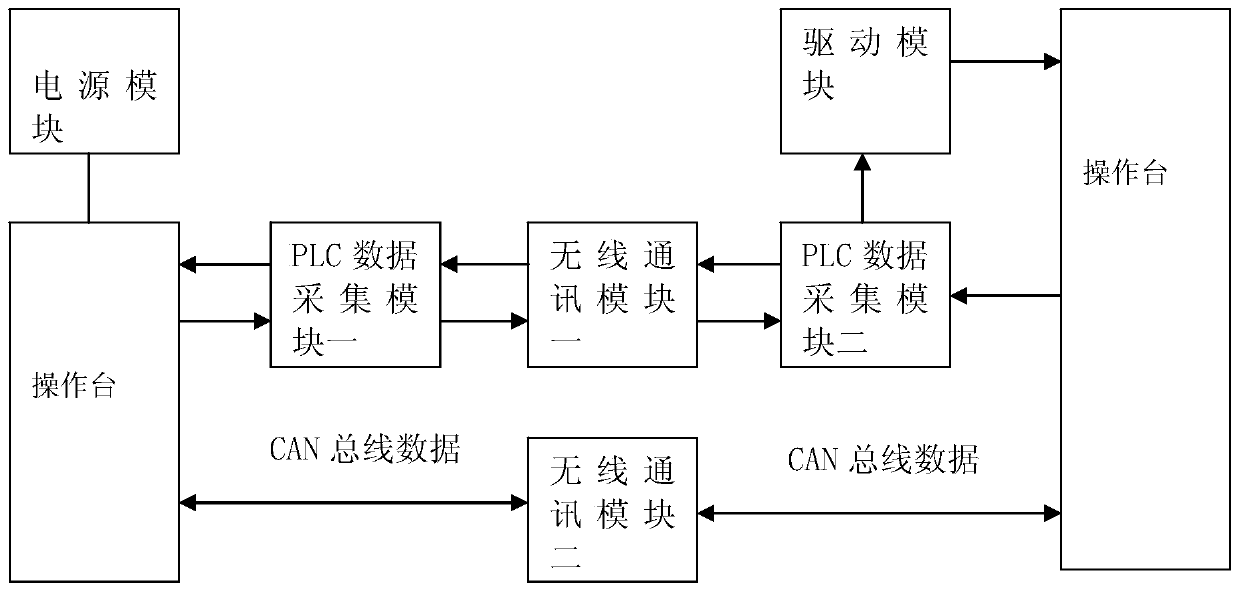

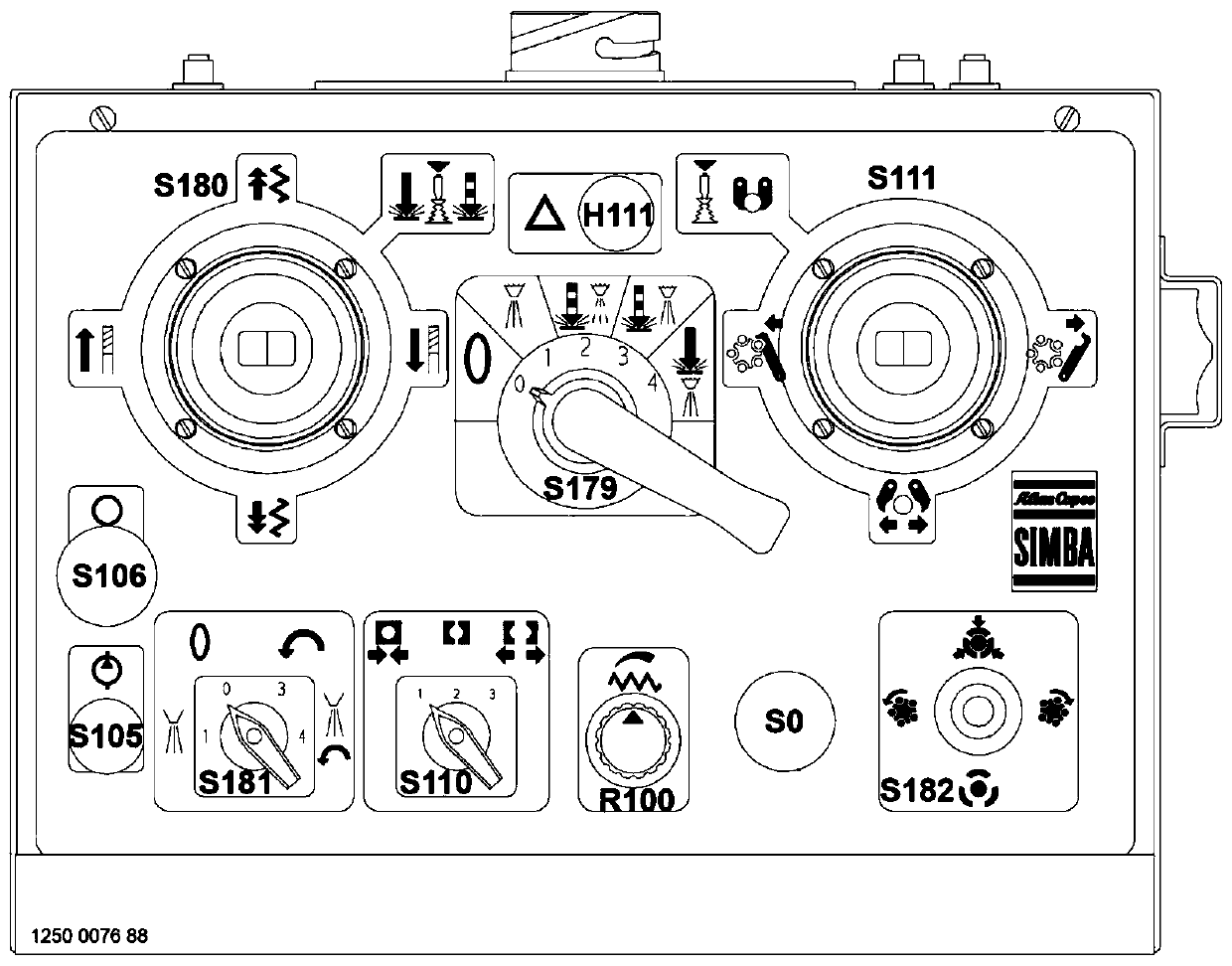

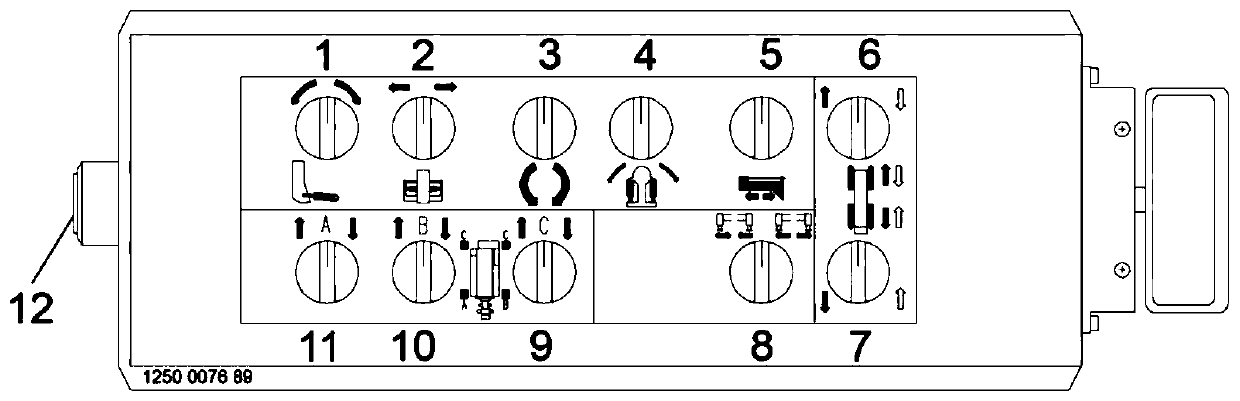

[0037] In this example, SIMBA H1354 is taken as an example to design a wireless control device to replace the wired connection of the two signal cables of the existing console, which can safely and stably realize the original console commands and data within a short distance (less than 50M). round-trip sending and receiving. Design and manufacture an independent wireless data transmission device, which transmits the control signal and operation status signal transmitted by the existing cable through the wireless data transmission device, without changing the operation mode of the existing equipment, and realizing all the functions of the original cable connection. The wireless transmission device requires stable and reliable operation, no malfunction, strong anti-interference ability, and the electromagnetic radiation index meets the requirements of the national standard. On the basis of determining the transformation content and requirements, determine the transformation plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com