Ground socket shell and manufacturing process

A ground socket and housing technology, applied in the manufacture of base/shell, contact box/base, etc., can solve the problems of unsightly appearance, low grade, affecting service life, etc. The effect of longevity and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

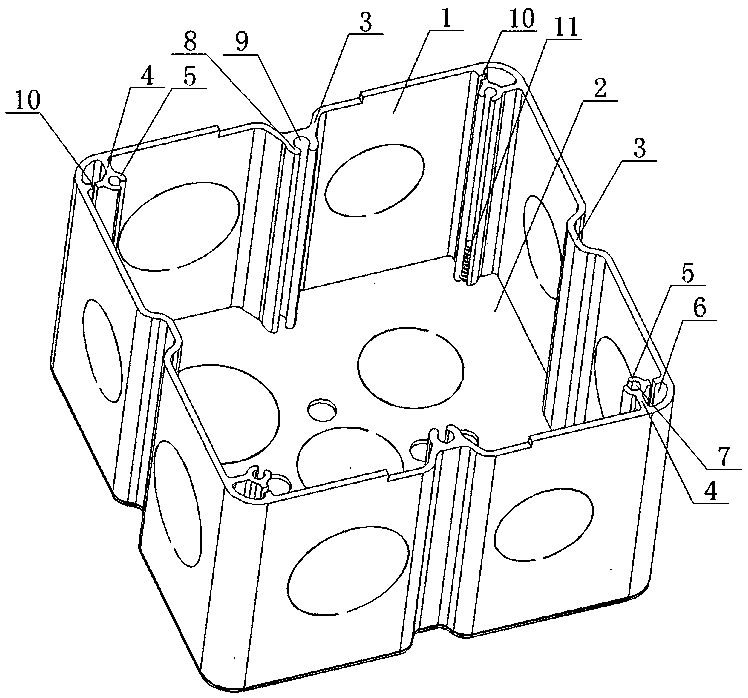

[0015] As shown in the figure, the ground socket housing of the present invention includes a base plate 2 and surrounding side plates, and the surrounding side plates are formed by cutting a square tube-shaped aluminum alloy profile 1 to a fixed length. The four corners of the aluminum alloy profile 1 are Arc angle, the inner side of the arc angle is provided with a reinforcing rib rib 4, the middle of the reinforcing rib rib 4 surrounds the middle cavity hole 6, and the outer edge of the reinforcing rib rib 4 is provided with a first C-shaped rib 5, The first C-shaped rib 5 surrounds the first C-shaped cavity hole 7, and one end of the reinforcing rib rib 4 is connected to the side wall corresponding to the aluminum alloy profile, and the other end is connected to the side wall corresponding to the aluminum alloy profile There is an elastic gap 10 penetrating up and down between them, and the width of the elastic gap 10 is not greater than 1mm; the center of the side wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com