Electronic unit

An electronic unit, electrical connection technology, applied in the direction of electrical components, printed circuits, electric components, etc., can solve the problems of substrate cracking, substrate strength deterioration, difficult to set grooves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

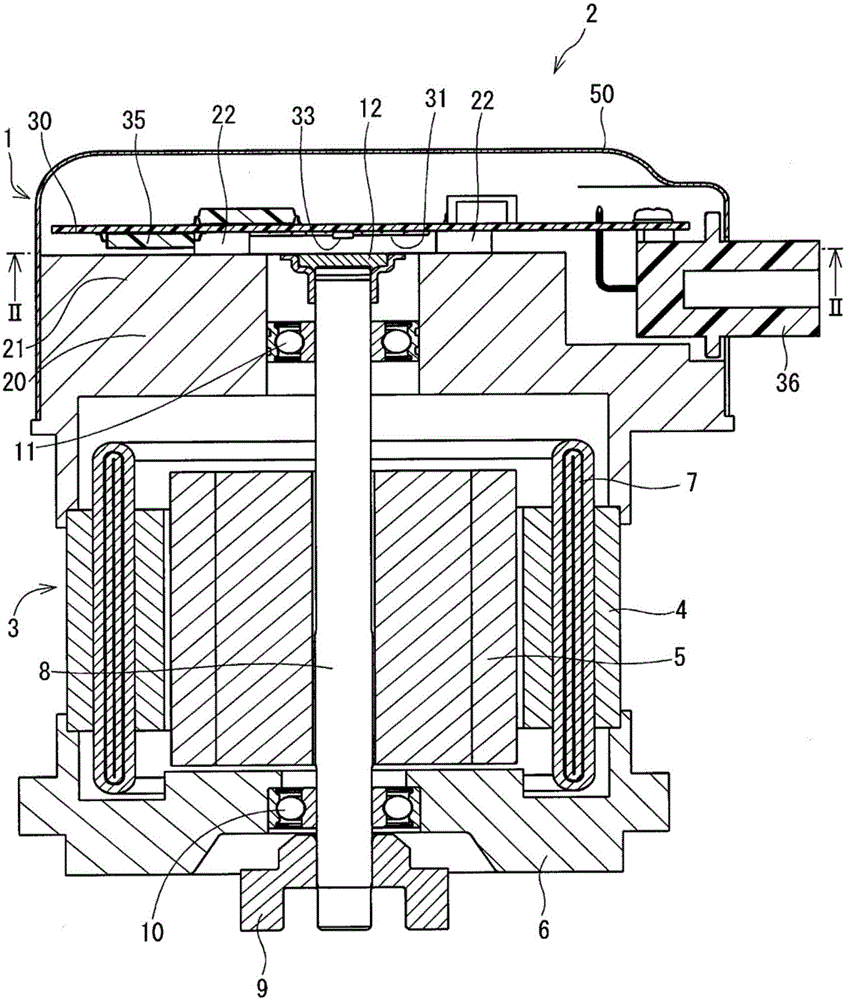

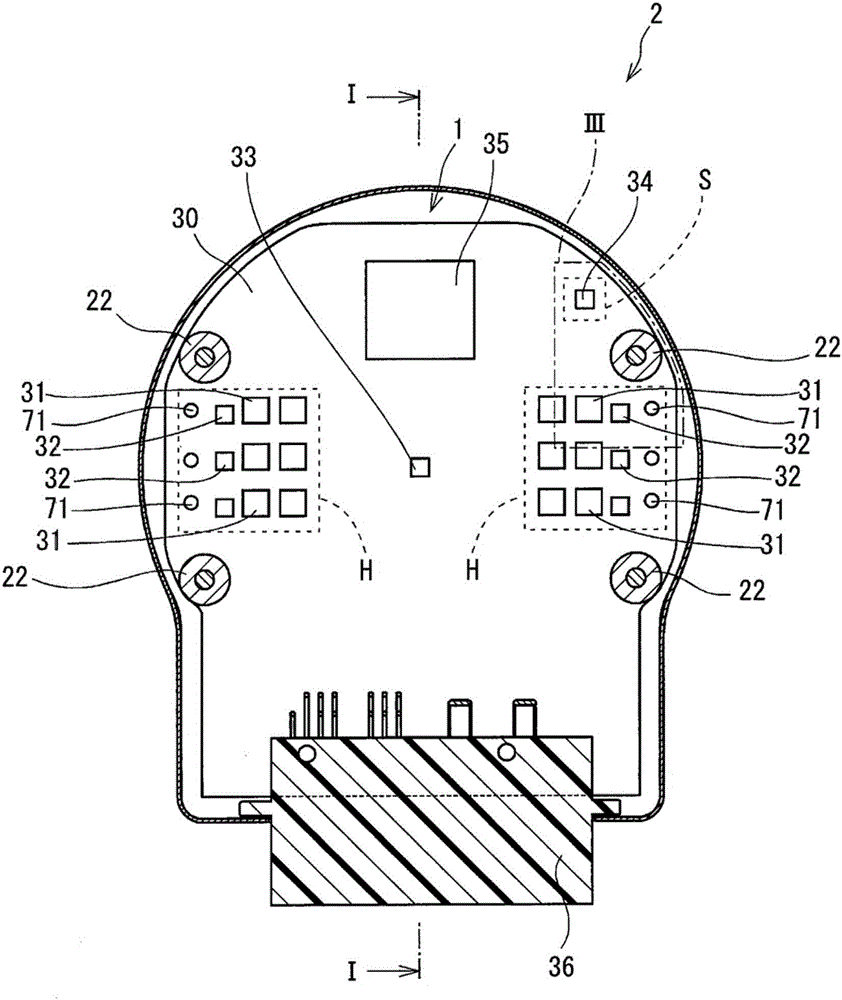

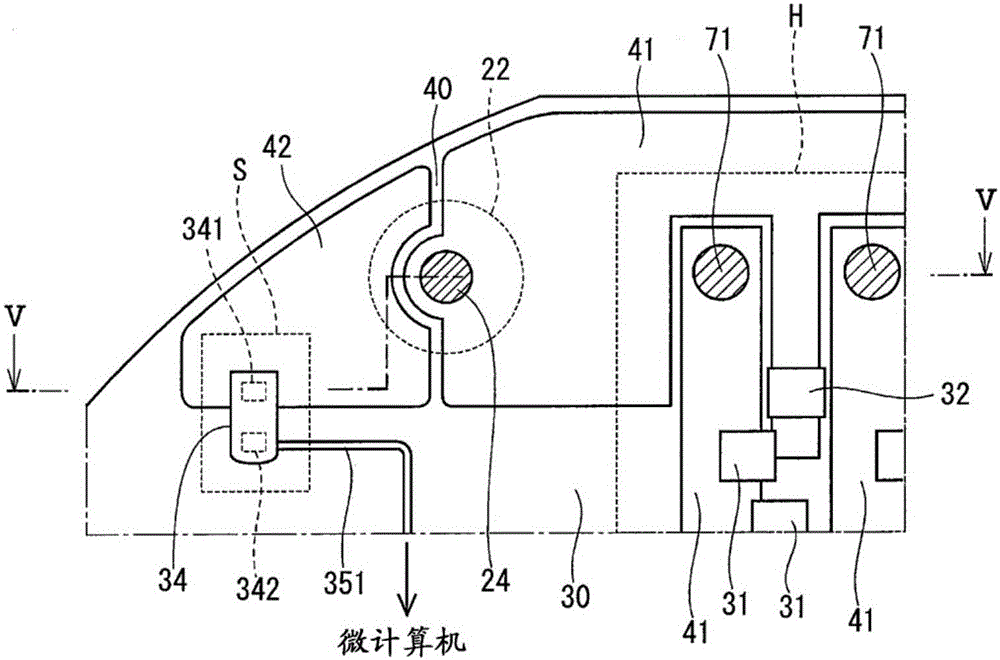

[0020] Figures 1 to 5 A first embodiment is shown in . The electronic unit 1 of the first embodiment is used in a drive device 2 that generates steering assist torque for an electric power steering system of a vehicle. Such as figure 1 As shown in , the driving device 2 includes a motor part 3 and an electronic unit 1 that controls the operation of the motor part 3 . The configuration of the motor section 3, the configuration of the electronic unit 1, and different configurations of the electronic unit 1 will be described in this order.

[0021] The configuration of the motor section 3 will be described below. The motor unit 3 includes a stator 4 and a rotor 5 . The stator 4 is formed in a cylindrical shape, and has one axial end fixed to the frame end 6 and the other axial end fixed to the heat sink 20 . The coil 7 is wound in the slots of the stator 4 . The rotor 5 has a cylindrical shape rotatably relative to the stator 4 inside the stator 4 in the radial direction. ...

no. 2 example

[0045] Figure 9 A second embodiment is shown in . In the second embodiment, the third interconnection 43 is provided in the surface layer of the substrate 30 . The third interconnect 43 has one end connected to the second interconnect 42 and the other end connected to the first interconnect 41 . The third interconnect 43 is provided meandering through the surface layer of the substrate 30 . When the third interconnect 43 is provided in the surface layer of the substrate 30 , the third interconnect 43 may be arranged separately from the region where the pillar 22 of the heat sink 20 is in contact with the surface layer of the substrate 30 . Furthermore, the third interconnection 43 may be arranged separately from the region where the head of the screw 24 is in contact with the surface layer of the substrate 30 . This limits the breaking of the third interconnection 43 due to the axial force of the screw 24 .

[0046] In the second embodiment, even if the screws 24 securing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com