Device for determining or monitoring the filling level of a filling material stored in a container

A filling material, filling level technology, used in measuring devices, lubrication indicating devices, instruments, etc., can solve problems such as vertex cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

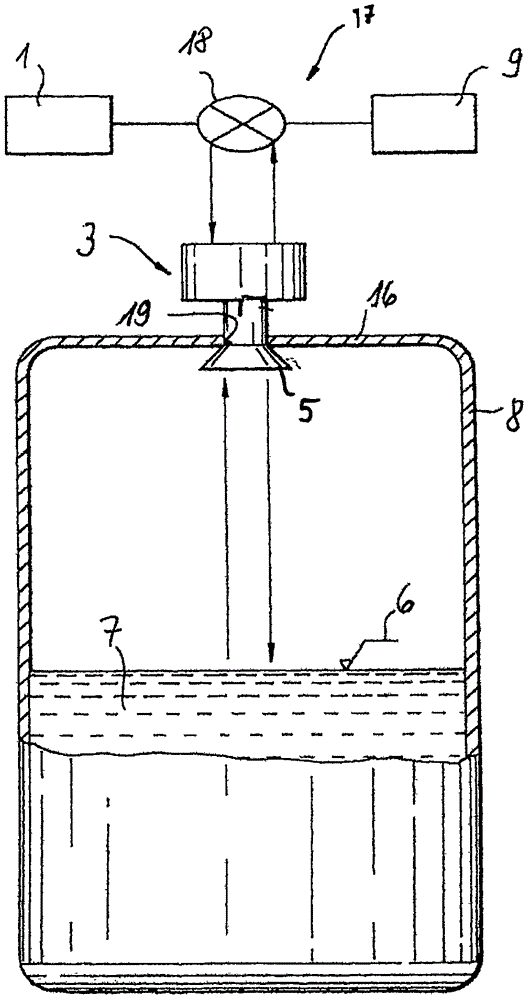

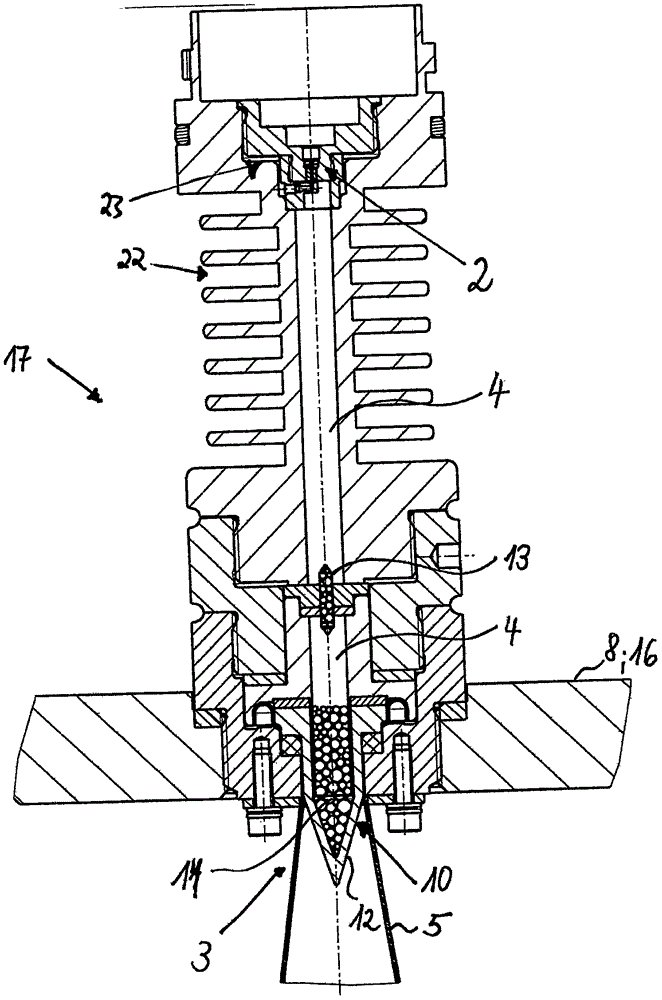

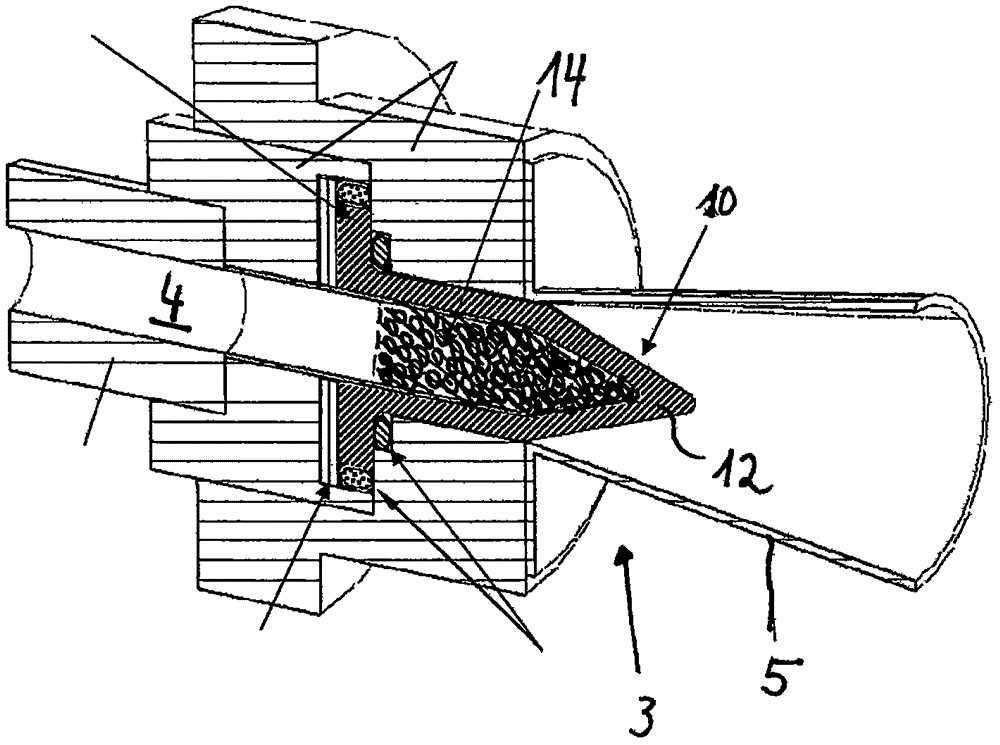

[0032] figure 1 A schematic diagram of an embodiment of the device according to the invention is shown. Filling material 7 , liquid or solid, is stored in container 8 . For determining the fill level of the filling material 7 in the container 8 is a fill level gauge 17 which is fitted in the opening 19 of the lid 16 of the container 8 . The microwave measurement signal generated in the signal generating unit 1 is coupled into the antenna unit 3 and emitted via the antenna 5 in the direction of the surface 6 of the filling material 7 . On the surface 6 the measurement signal is at least partially reflected as an echo signal. The echo signals are received by the antenna unit 3 and passed into the control / evaluation unit 9 for the purpose of adjusting and evaluating the fill level measurement. The control / evaluation unit 9 is assigned to a delay circuit as described, for example, in DE 3107444 A1. The correct timing of the transmission of the measurement signal and the recept...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com