Organic-inorganic compound fertilizer prepared from high-pressure partial oxidation-process coal gasification waste residues and preparation method of organic-inorganic compound fertilizer

A high-pressure part, oxidation technology, applied in organic fertilizers, inorganic fertilizers, urea compound fertilizers, etc., can solve the problems of easy soil compaction, reduced organic matter content, low utilization rate of soil fertilizers, etc., to improve soil structure and increase fruit hardness. , the effect of improving nutrient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

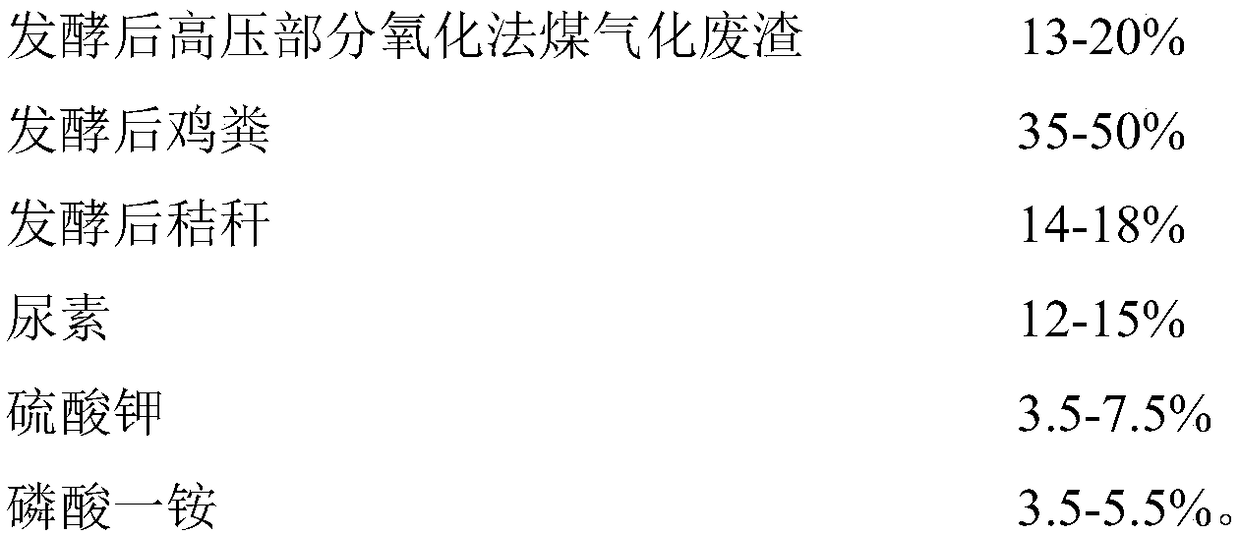

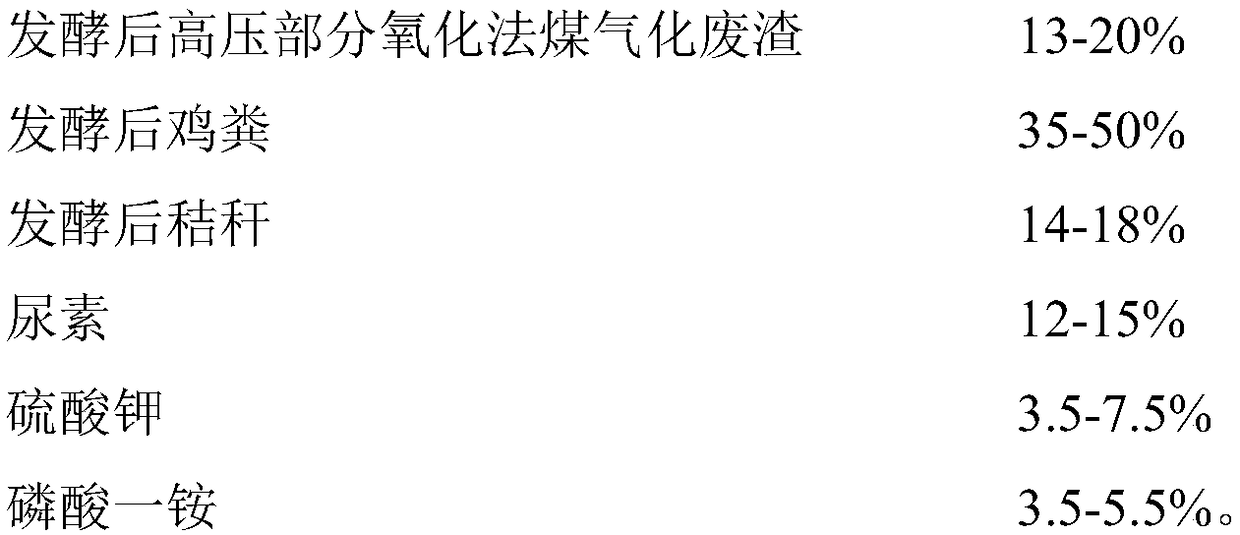

[0023] A method for preparing a special fertilizer for vegetables, melons and fruits prepared by using high-pressure partial oxidation method coal gasification waste residue, the preparation method comprising the following steps:

[0024] ①Crush the corn stalks to 0.5-1cm;

[0025] ②According to the mass percentage, mix 17.5% high-pressure partial oxidation process coal gasification waste residue, 42.5% chicken manure, 16% crushed corn stalks and water, so that the carbon-nitrogen ratio is 20, and the amount of water added is high-pressure partial oxidation process coal gasification waste residue, chicken manure 64% of the weight of manure and straw, adding fermentative agent for aerobic fermentation, the amount of fermentative agent added is 0.3% of the weight of the mixture of high-pressure partial oxidation process coal gasification waste residue, chicken manure and straw, when the pile temperature is 8-15 ℃, add brown sugar to make it ferment, when the temperature of the h...

Embodiment 2

[0029] A preparation method of special fertilizer for flowers and gardens prepared by high-pressure partial oxidation process coal gasification waste residue, said preparation method comprising the following steps:

[0030] ①Crush the corn stalks to 0.5-1cm;

[0031] ②According to the mass percentage, mix 17.5% high-pressure partial oxidation process coal gasification waste residue, 42.5% chicken manure, 16% crushed corn stalks and water, so that the carbon-nitrogen ratio is 20, and the amount of water added is high-pressure partial oxidation process coal gasification waste residue, chicken manure 64% of the weight of manure and straw, adding fermentative agent for aerobic fermentation, the amount of fermentative agent added is 0.3% of the weight of the mixture of high-pressure partial oxidation process coal gasification waste residue, chicken manure and straw, when the temperature of the pile is 8-15 ℃, add brown sugar to make it ferment, when the temperature of the heap body...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com