Bridge hierarchical drainage system applied to steel bridge deck

A drainage system and steel bridge deck technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of affecting vehicle driving, rainwater cannot be drained in time, bridge area water, etc., and achieve the effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

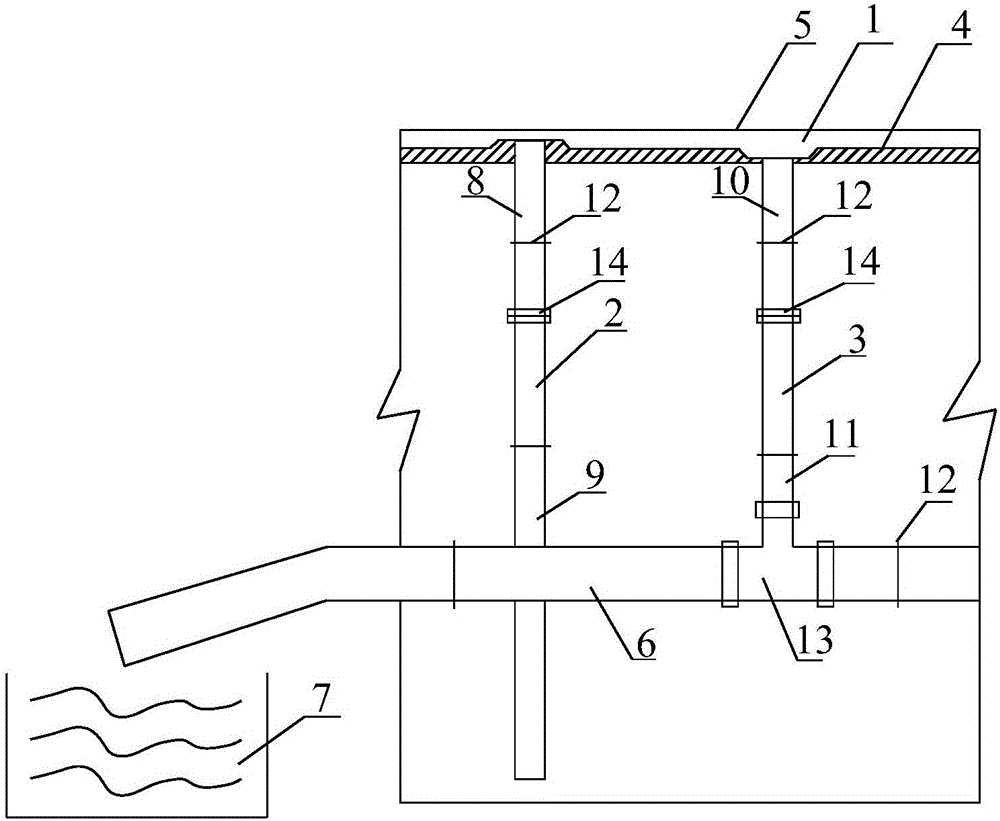

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] see figure 1 As shown, the present invention provides a bridge graded drainage system suitable for steel bridge decks, comprising a shallow drainage ditch 1, the shallow drainage ditch 1 is located on both sides of the bridge deck, and the bottom 4 of the shallow drainage ditch 1 is lower than the bridge deck , when it is convenient to rain, the rainwater on the bridge deck can flow into the shallow drainage ditch 1, and the shallow drainage ditch 1 is arranged on the inner side of the bridge guardrail. It also includes a plurality of vertically arranged straight pipes 2 and collecting pipes 3, the water inlets of the straight pipes 2 and the collecting pipes 3 are located in the shallow drainage ditch 1, and the water inlets of the straight pipes 2 are higher than the drainage shallows. The ditch bottom 4 of the ditch 1 is lower than the ditch surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com