Saddle-Ride Type Vehicular Dry Clutch Having Passive Clutch Disc Of Co-Axial Fixed Plane Contact

一种干式离合器、离合片的技术,应用在自动离合器、机械驱动离合器、离合器等方向,能够解决结构整体损毁断裂、离合器壳25结构损害难、裂痕等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The aforementioned and other technical content, features and effects of the present invention will be clearly presented in the following detailed description of the preferred embodiments in conjunction with the accompanying drawings; in addition, in each embodiment, the same elements will be similar The label indicates.

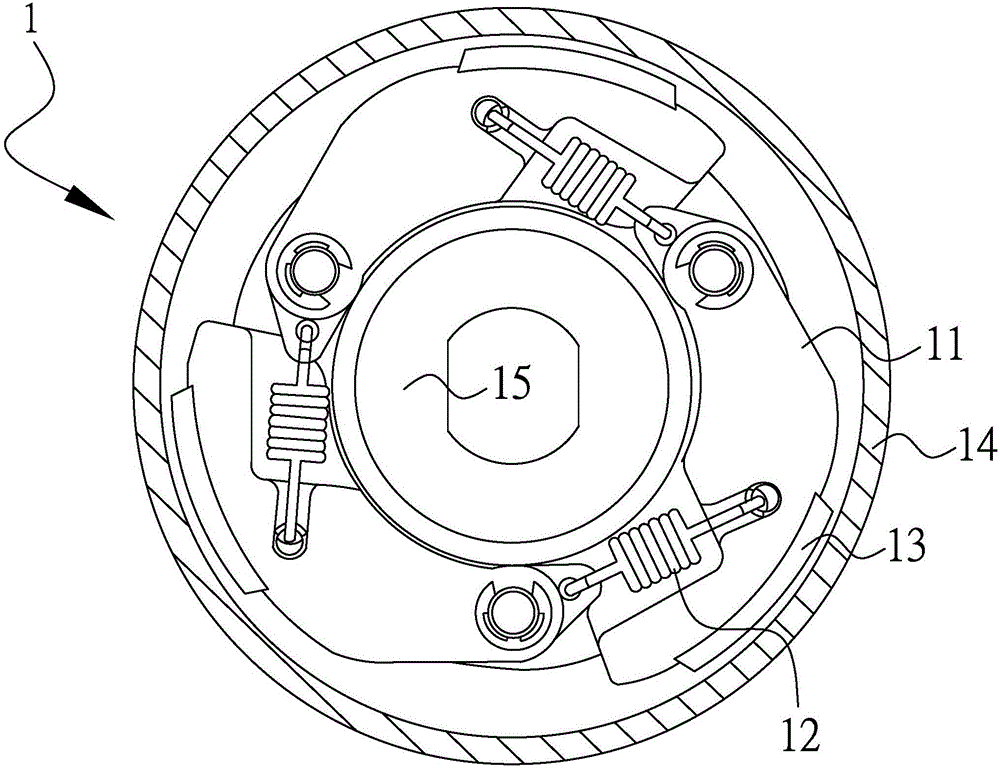

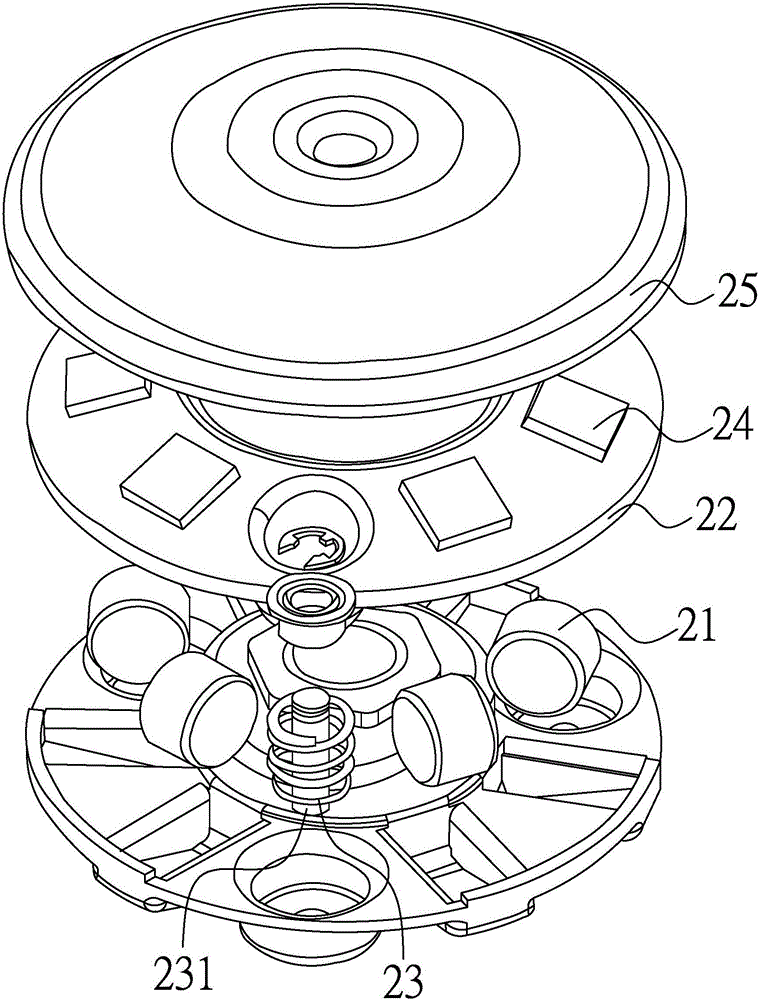

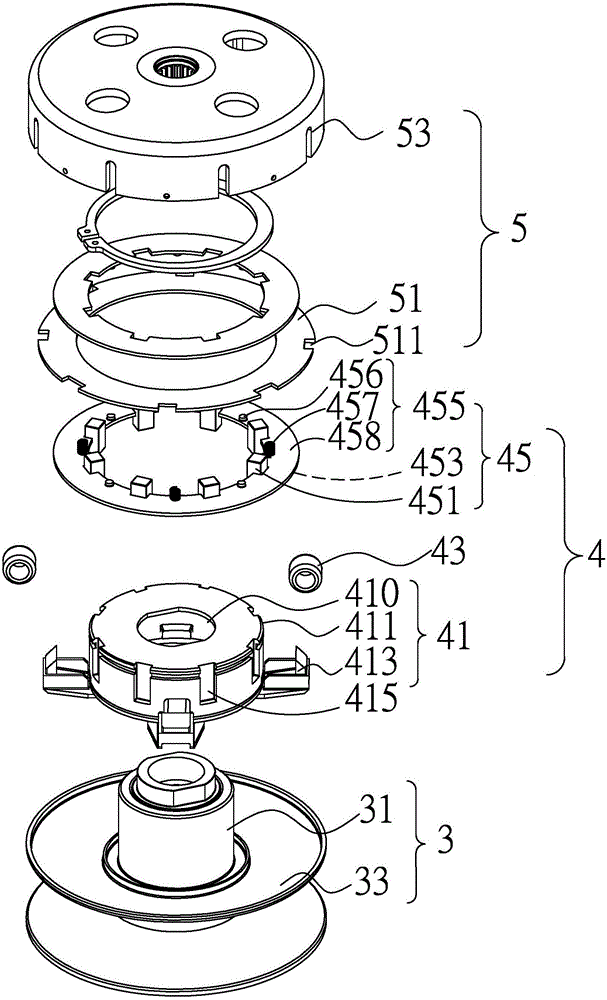

[0047] In this example, a dry clutch such as Figure 7 As shown, it is assembled near the rear wheel of the motorcycle, and its clutch action can be regarded as the start switch of the whole locomotive, such as image 3 As shown, when the engine (not shown) maintains a constant idle speed (for example: 2000 rpm), the driving bearing 3 composed of the bearing body 31 and the driving disc 33 synchronously operating with the bearing body 31 bears the energy transmitted by the engine. Then, the rotation speed of the drive bearing 3 determines whether the clutch device 4 is smoothly linked. The clutch device 4 is sleeved on the bearing body 31 with the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com