Bridgehead settlement compensation amount test device and method

A test device and compensation technology, applied in the direction of material inspection products, etc., can solve the problems of material performance change, road surface structure affected by force, etc., achieve the effect of compact structure, ensuring accuracy, and saving research funds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

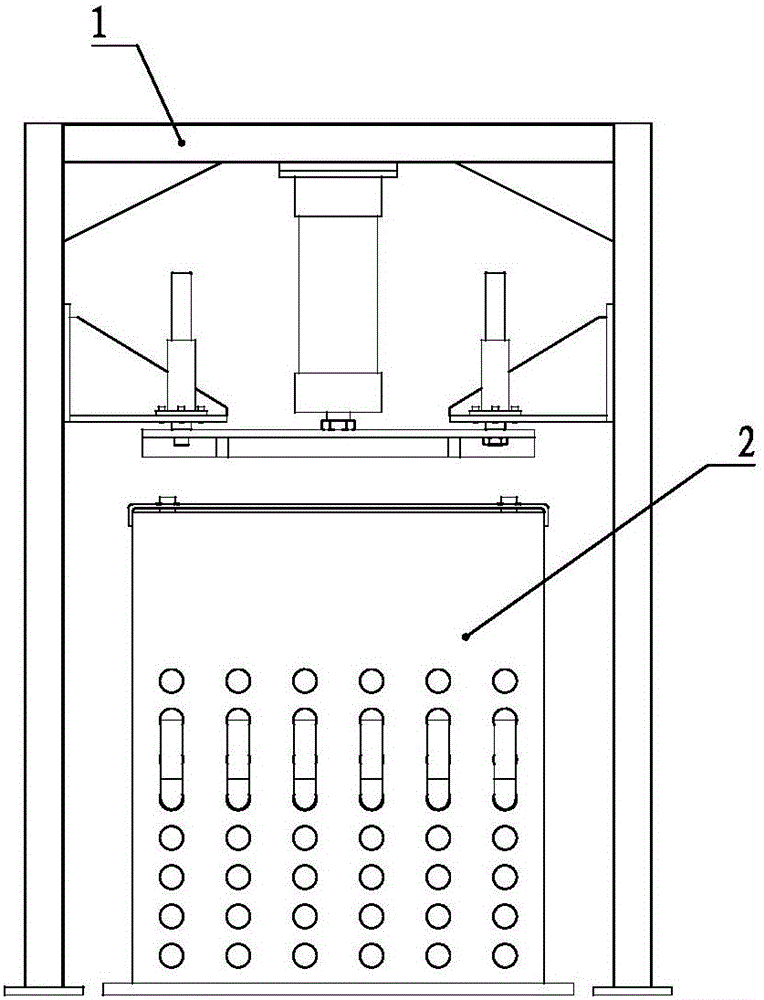

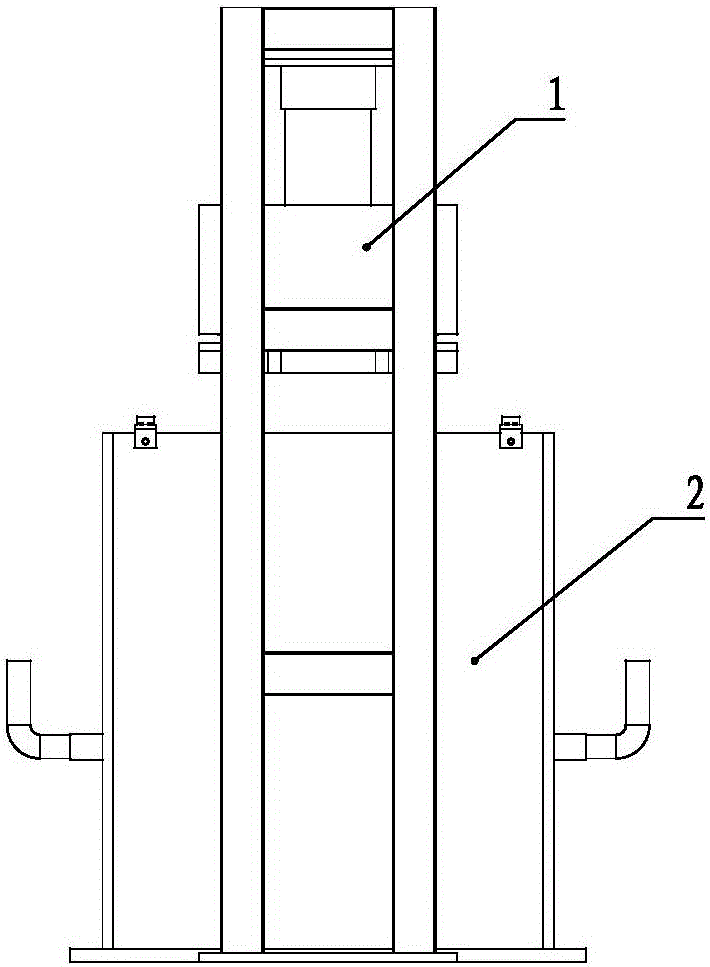

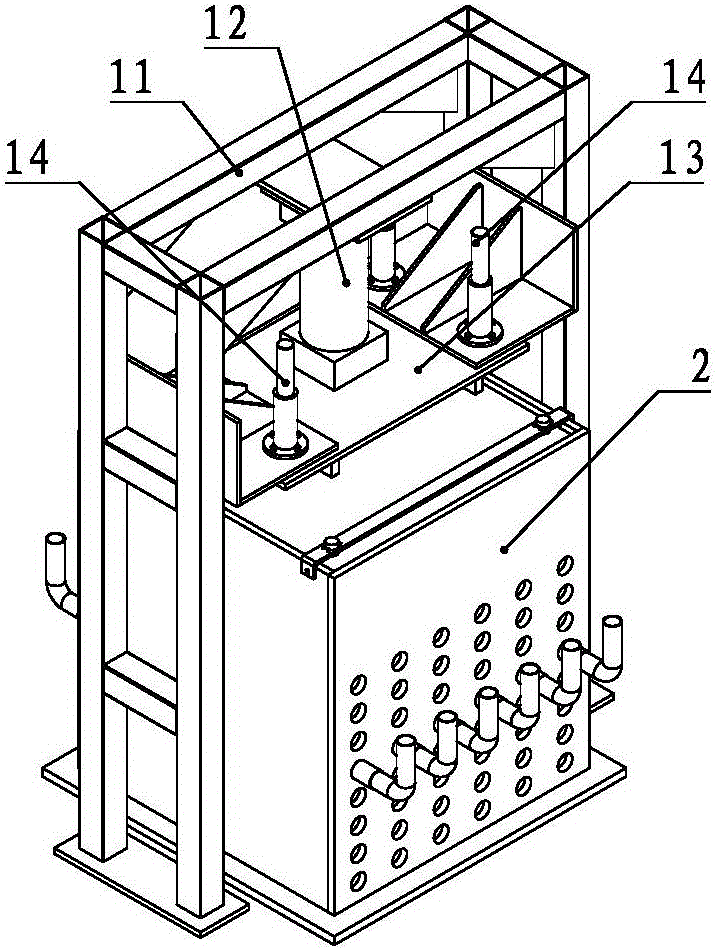

[0073] like Figure 1 to Figure 3 As shown, the bridgehead settlement compensation test device includes a pressurization unit 1, a model box 2 and a control system, and the pressurization unit 1 and the model box 2 adopt a split structure, and the model box 2 It is arranged inside the pressurizing unit 1 .

[0074] like Figure 4 As shown, the pressurizing unit 1 includes a frame 11 , an oil cylinder 12 , a pressure head 13 and a guide mechanism 14 . The frame 11 is in the shape of a "door" and includes a first leg 111 , a second leg 112 and a beam 113 arranged on the top of the first leg 111 and the second leg 112 . In order to increase the stiffness of the whole frame 11, as Figure 7 As shown, the first leg 111 and the second leg 112 are square frames welded by several square steel pipes, and the crossbeams 113 are two, which are respectively arranged on the first leg 111 Ribs 114 are provided between the first leg 111 and the beam 13 and between the second leg 112 and ...

Embodiment 2

[0083] like Figure 16 As shown, the pressurization unit includes an indenter placed on the second press plate, on which a heavy object of a certain weight is placed, and the subgrade pavement model is pressurized by the gravity of the heavy object itself. All the other structures are the same as in Embodiment 1.

[0084] A method for testing bridgehead settlement compensation, comprising the following steps:

[0085] a), set the subgrade pavement model, the subgrade pavement model is successively subgrade, subbase, base and surface layer from bottom to top, and a compensation layer is arranged in the subgrade wherein, the specific parameters are:

[0086] The pre-embedded depth of the compensation layer is 70cm, and the thickness is 11cm;

[0087] The mixing ratio of gypsum and fly ash in the compensation layer is 1:2;

[0088] The materials of the road base, subbase, base and surface course are well-graded gravel mixture, fly ash-alkali slag stabilized soil, cement stabil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com