Preparation method and application of corn amylose supported catalyst

A supported catalyst and corn starch technology, applied in catalytic reactions, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as difficult recycling, environmental pollution, etc., and achieve simple preparation, low price, and natural abundance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

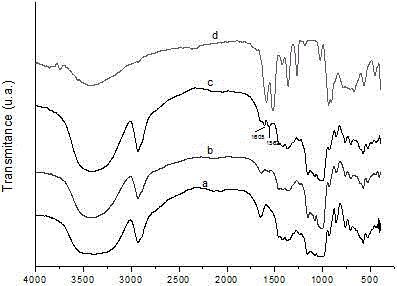

[0017] A kind of preparation method of amylose cornstarch supported catalyst, its preparation method reaction formula is:

[0018]

[0019] The specific preparation method comprises the following steps:

[0020] (1) The amylose cornstarch is firstly expanded to increase the specific surface area and pore volume to prepare rigid and porous expanded cornstarch;

[0021] (2) react with 3-aminopropyl triethoxy silicon to prepare aminated cornstarch,

[0022] (3) Schiff base reaction with acetylacetone metal complex, and condensation to obtain amylose corn starch-supported catalyst.

[0023] The step (1) prepares rigid and porous expanded corn starch: add 2-8 g of amylose corn starch, add 20-200 mL of deionized water, and heat at 100-130°C for 40-50 min to obtain a gel, and placed in a refrigerator at 5°C for 24 h; after filtration, the solid was washed with ethanol to obtain rigid and porous expanded cornstarch.

[0024] The step (2) prepares the aminated expanded cornstarch...

Embodiment 1

[0035] Preparation of Amylose Corn Starch Supported Catalyst.

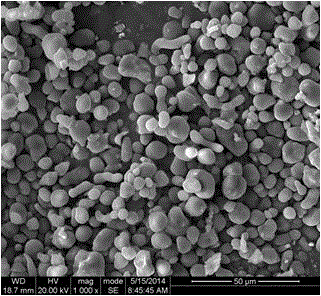

[0036] Preparation of rigid and porous expanded corn starch: 5 g of high-amylose corn starch was added to 100 mL of deionized water, heated at 120 °C for 45 min to obtain a gel, and placed in a refrigerator at 5 °C for 24 h. After filtration, the solid was washed with ethanol to obtain a rigid porous expanded cornstarch.

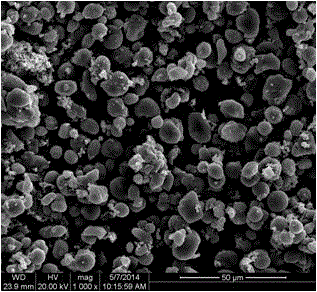

[0037] Preparation of aminated expanded cornstarch: 4.23 g of expanded cornstarch, 35 mL of dry toluene, under the protection of nitrogen, slowly add 4.82 g of 3-aminopropyltriethoxysilane dropwise, and react under reflux for 24 h, after the reaction is finished, cool to room temperature, add 135 mL of ethanol, after filtering, wash with ethanol to obtain aminated expanded cornstarch;

[0038] Preparation of amylose-loaded catalyst: 2 g of aminated expanded corn starch, 0.3 g of molybdenum acetylacetonate, reflux reaction in toluene solution under nitrogen protection for 24 h, filtered after th...

Embodiment 2

[0043] Applications of amylose-supported catalysts.

[0044] Preparation of anhydrous tert-butyl hydroperoxide (TBHP): 1 mL of TBHP was extracted three times with 1 mL of toluene, the organic phases were combined and dried with anhydrous sodium sulfate to obtain anhydrous tert-butyl hydroperoxide (TBHP) .

[0045] Add 0.97 g of anhydrous TBHP to 1 g of tallow catalpa oil, 0.29 g of amylose-loaded catalyst, and react for 2 h under toluene reflux. After the reaction, remove the catalyst by filtration, put the filtrate in an ice bath, and add 15% Sodium thiosulfate aqueous solution, and indicated by starch solution with iodine added, the organic phase was separated, dried with anhydrous sodium sulfate, filtered, and the solvent was distilled off under reduced pressure to obtain epoxidized vegetable oil with a conversion rate of 78.5%. The yield was 67.1%, and the selectivity was 85.5%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap