Mine jaw crusher capable of being controlled remotely

A jaw crusher, remote control technology, applied in the field of mining equipment, can solve the problems of arranging reinforcing ribs, physical injury, difficulty in improving work efficiency, etc., to reduce noise, prevent personal accidents, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

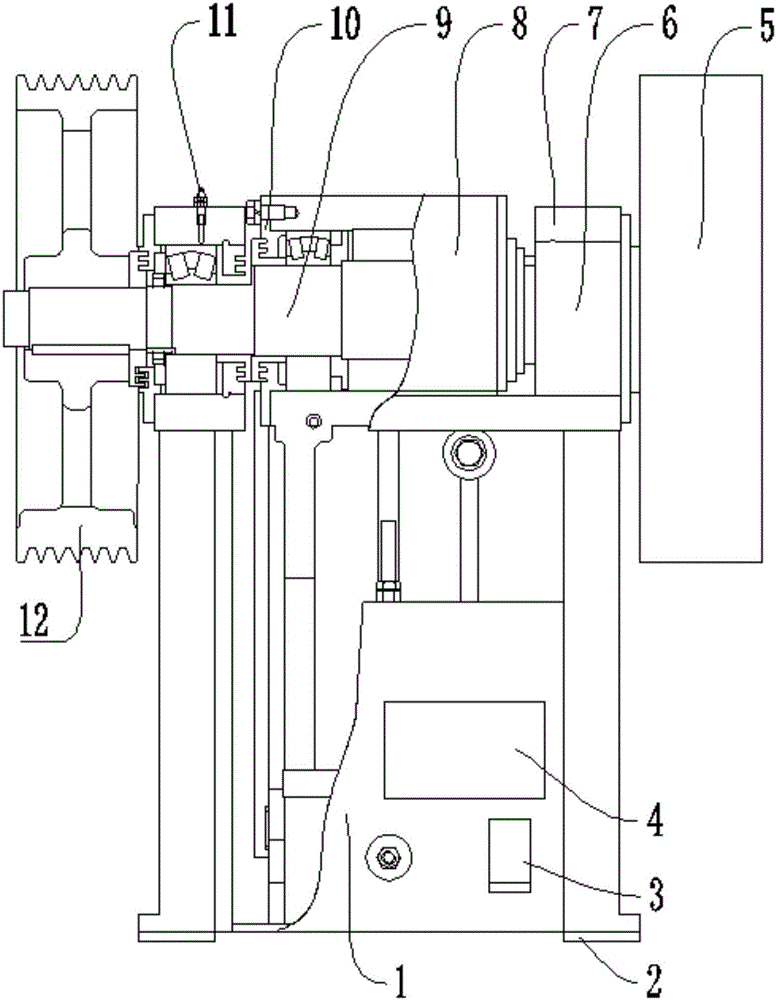

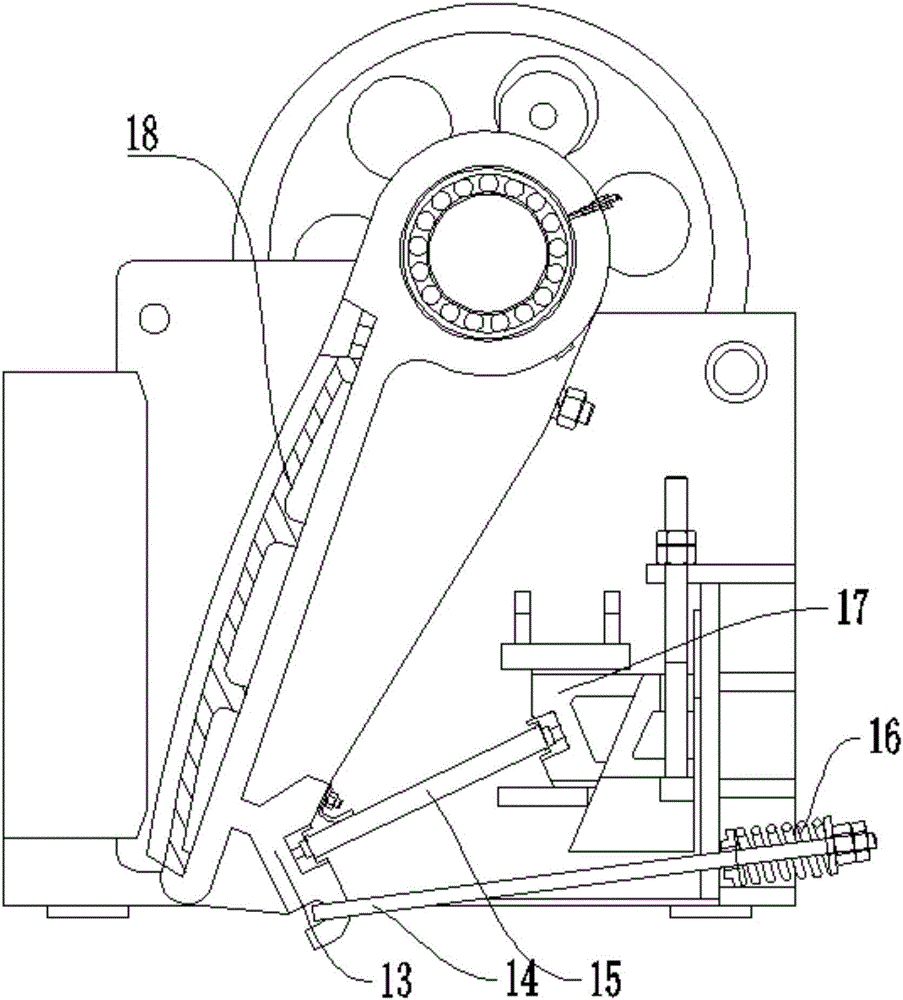

[0015] The present invention will be further described below in conjunction with accompanying drawing:

[0016] like Figure 1-Figure 2 As shown, a remote-controllable mine jaw crusher includes a bed 1, a box body 8, a main shaft 9, and a pulley 12. A balance backing plate 2 is arranged under the bed 1, and the balance backing plate 2 is used to maintain the equipment level, a remote controller 3 is arranged beside the balance pad 2, and the remote controller 3 is used to remotely operate the equipment. 4. There is a box 8 next to it. The box 8 is used to install the main shaft 9. The main shaft 9 is arranged inside the box 8. The main shaft 9 is used to provide the installation splint 18. There is a pulley 12 next to the main shaft 9. The pulley 12 is used to provide crushing power. , There is a bearing seat 6 next to the pulley 12, the bearing seat 6 is used to install the main shaft 9, a gland 7 is arranged next to the bearing seat 6, the gland 7 is used to install the lub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com