Production process of aluminum formwork

A production process and aluminum formwork technology, which is applied in the field preparation of formwork/formwork components, building components, construction, etc., can solve the problems of uneven stripes on the wall surface, waste of time, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

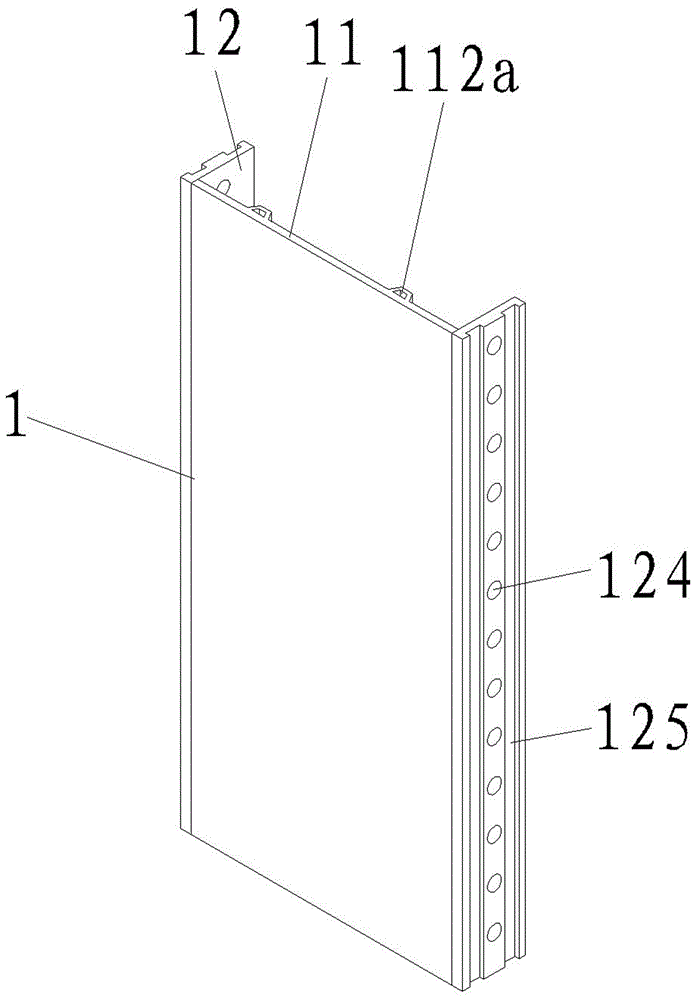

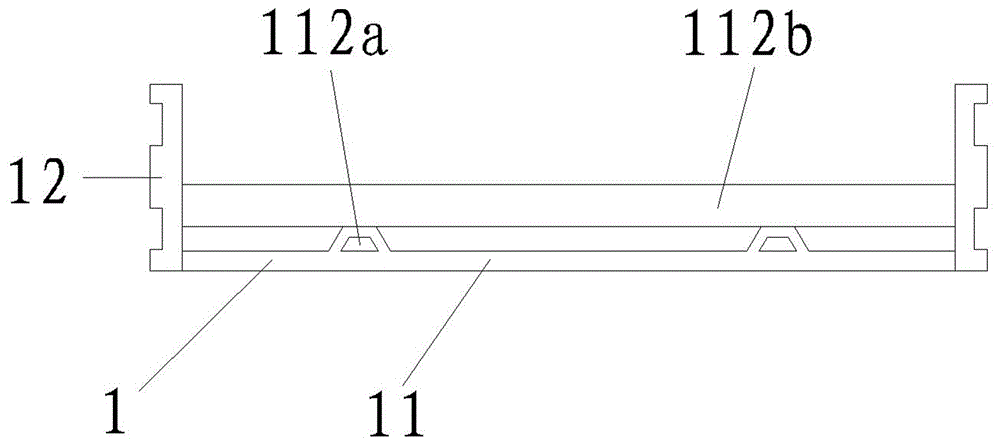

[0022] Such as figure 1 and figure 2 The production process of the shown aluminum formwork unit 1 is as follows:

[0023] A production process of aluminum formwork, comprising the following steps:

[0024] Purchasing an aluminum plate with a specific shape and processing it to form an aluminum formwork unit 1 of a specified shape. The aluminum formwork unit 1 includes a main board 11 and a connecting plate 12. The main board 11 includes a supporting surface and a working surface. The applicant selects the supporting surface when purchasing The aluminum formwork unit 1 with two channels 112a, because the channel 112a on this plate is integrated with the aluminum formwork unit 1, it does not require further processing by the applicant, and it can also increase the structural strength of the entire aluminum formwork unit 1 The enlargement will not be deforme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com