Automatic assembling system for carrier box and light guiding pillar of electric energy meter

An automatic assembly and light guide column technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of cumbersome procedures and low efficiency, and achieve the effects of improving production efficiency, avoiding damage, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

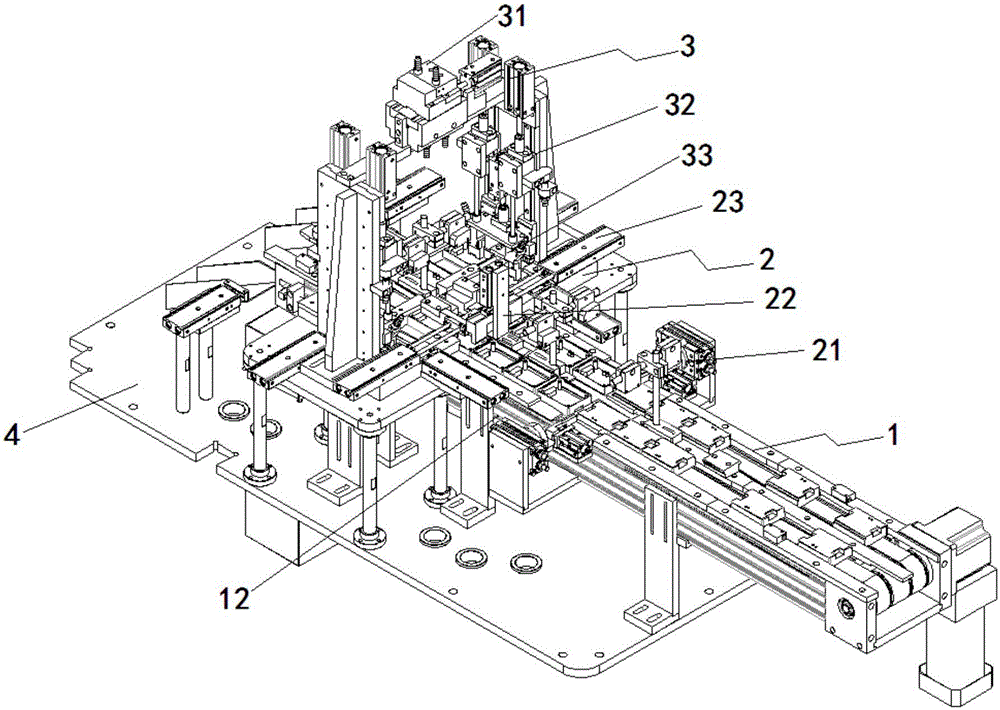

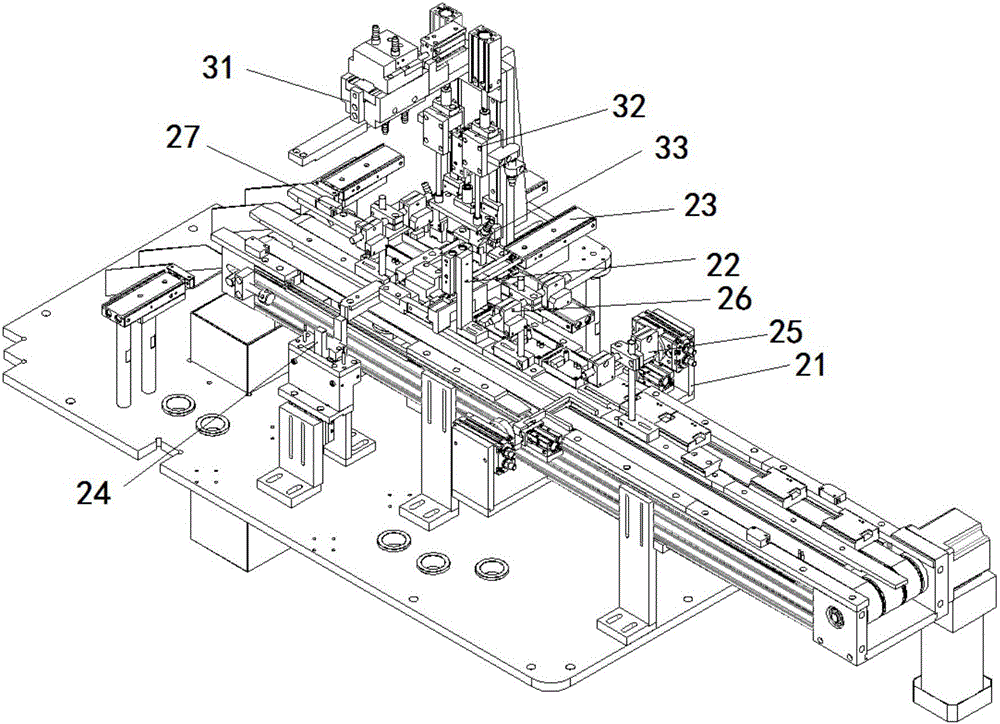

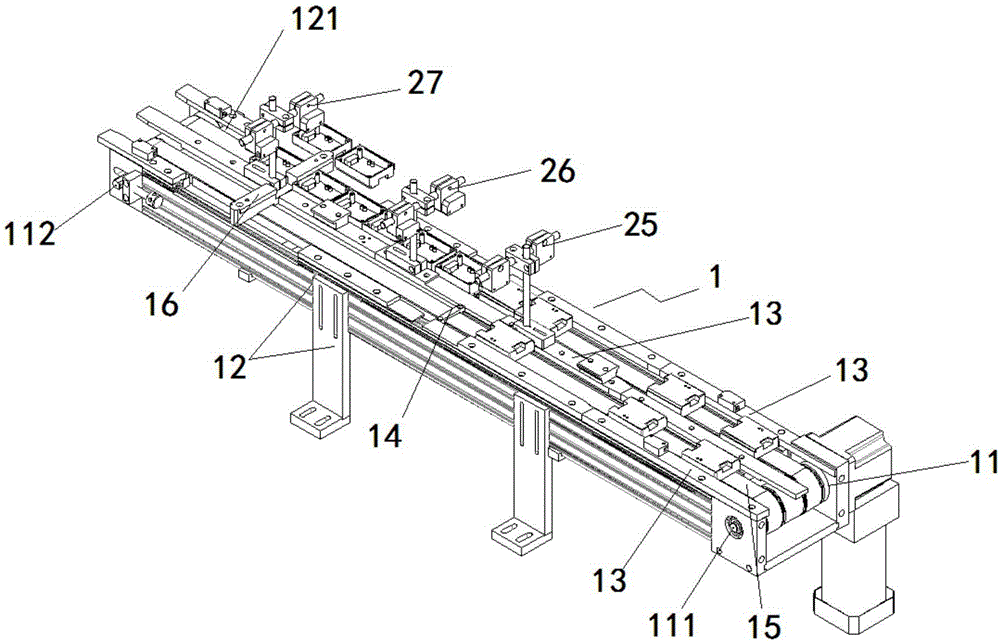

[0080] This embodiment provides as Figure 1-10 An automatic assembly system for the light guide column of the carrier box of the electric energy meter is shown, such as figure 1 As shown, it includes: a device frame 4 , a carrier box delivery device 1 , a carrier box adjustment device 2 and a light guide column automatic assembly device 3 . Such as figure 1 As shown, the carrier box conveying device 1 is arranged on the device frame 4, and is used to transport the parts or finished products of the carrier box to the turnover box; the carrier box adjusting device 2 is used to transfer the carrier box conveying device The carrier box in the upper 1 is adjusted from the initial posture to a press-in posture suitable for pressing the light guide column; the light guide column automatic assembly device 3 presses the light guide column into the carrier box in the press-in posture.

[0081] It should be noted that the carrier box delivery device 1, the carrier box adjustment devic...

Embodiment approach

[0087] The carrier box adjustment device 2 includes: a carrier box flip adjustment mechanism, a carrier box position adjustment mechanism and a carrier box positioning mechanism 24 . Wherein, the carrier box inversion adjustment mechanism 21 completes the inversion of the carrier box on the carrier box conveying device 1 . The carrier box position adjustment mechanism includes a shift mechanism 23, and the shift mechanism 23 shifts the carrier box from the carrier box conveying device 1 to the working area, or shifts the carrier box from the working area to the carrier Box delivery device 1; the carrier box positioning mechanism 24 is arranged in the working area for positioning the carrier box located in the working area, and the carrier box positioning mechanism 24 includes a positioning cylinder 241 and a positioning claw, The positioning claws are driven by the positioning cylinder 241 to position the carrier box that has been assembled with the light guide column. It sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com