Efficient automatic pin mounting mechanism

A needle-loading and automatic technology, which is applied in mechanical equipment, metal processing, bearing components, etc., to reduce vibration and noise, improve assembly efficiency, and save manual assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make those skilled in the art more clearly understand the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to the following embodiments.

[0033] In the description of the present invention, it should be noted that, unless otherwise specified and limited, those skilled in the art can understand the specific meanings of the general terms in the present invention according to specific situations.

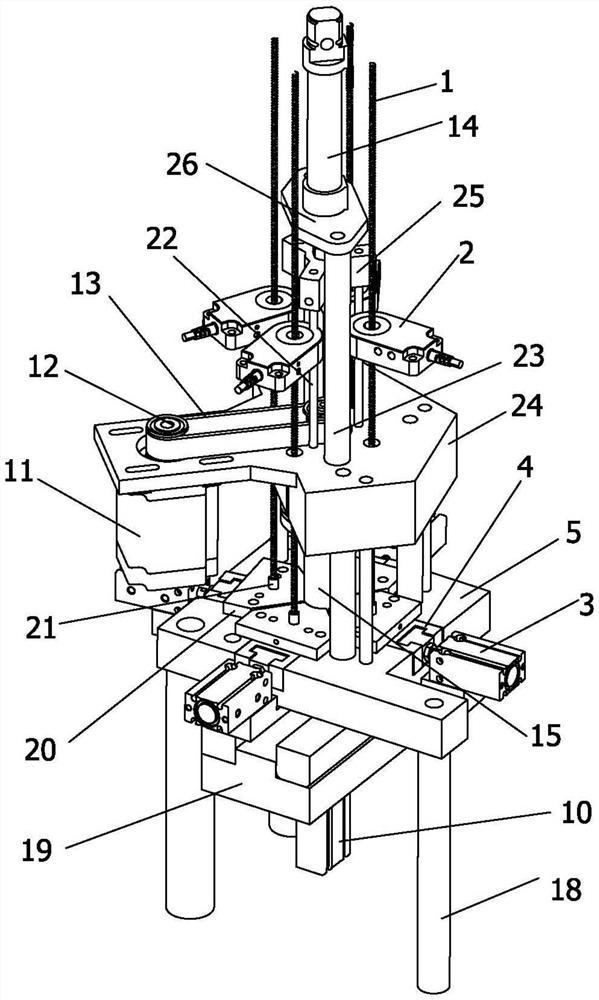

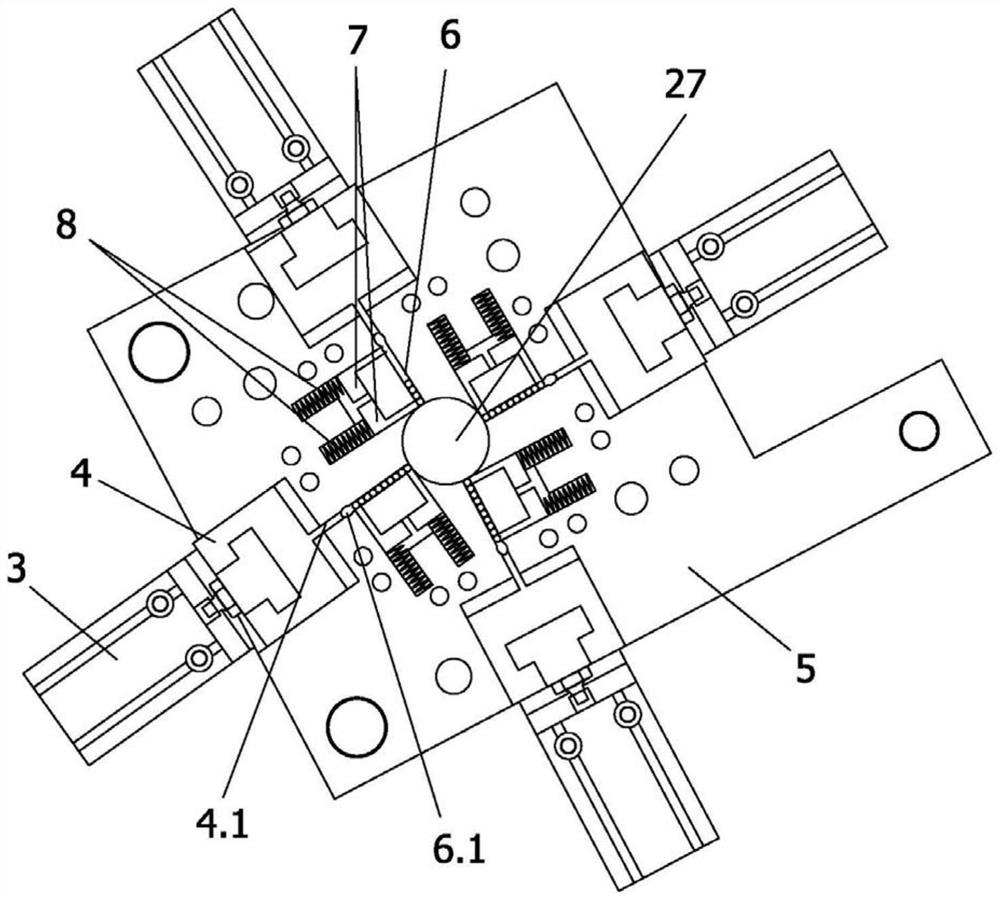

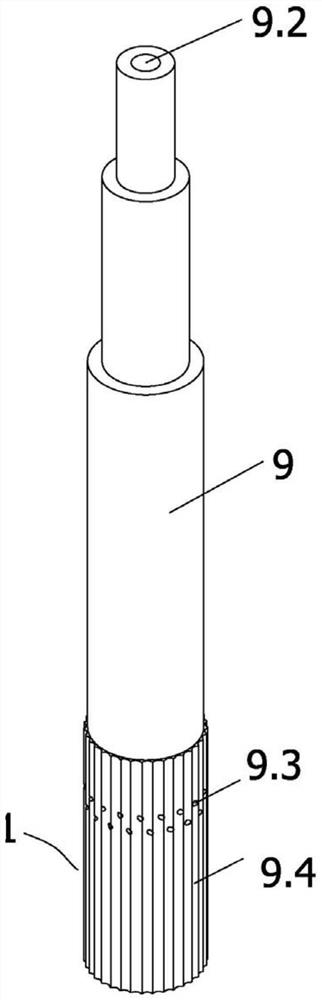

[0034] Such as Figure 1 to Figure 7 As shown, a high-efficiency automatic needle loading mechanism provided by the present invention includes a frame 18 with a square base 5 horizontally arranged on the top, at least one sleeve feeding assembly installed at the bottom of the square base 5, and an upper side of the square base 5. At least one blanking assembly (four blanking assemblies are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com