Paper shredder core assembly equipment

A technology for assembling equipment and paper shredders, which is applied in the direction of assembling machines, metal processing equipment, metal processing, etc., can solve the problems of cumbersome operation process, many assembly steps, and high labor costs, so as to reduce manufacturing costs, reduce labor costs, and improve The effect on business productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

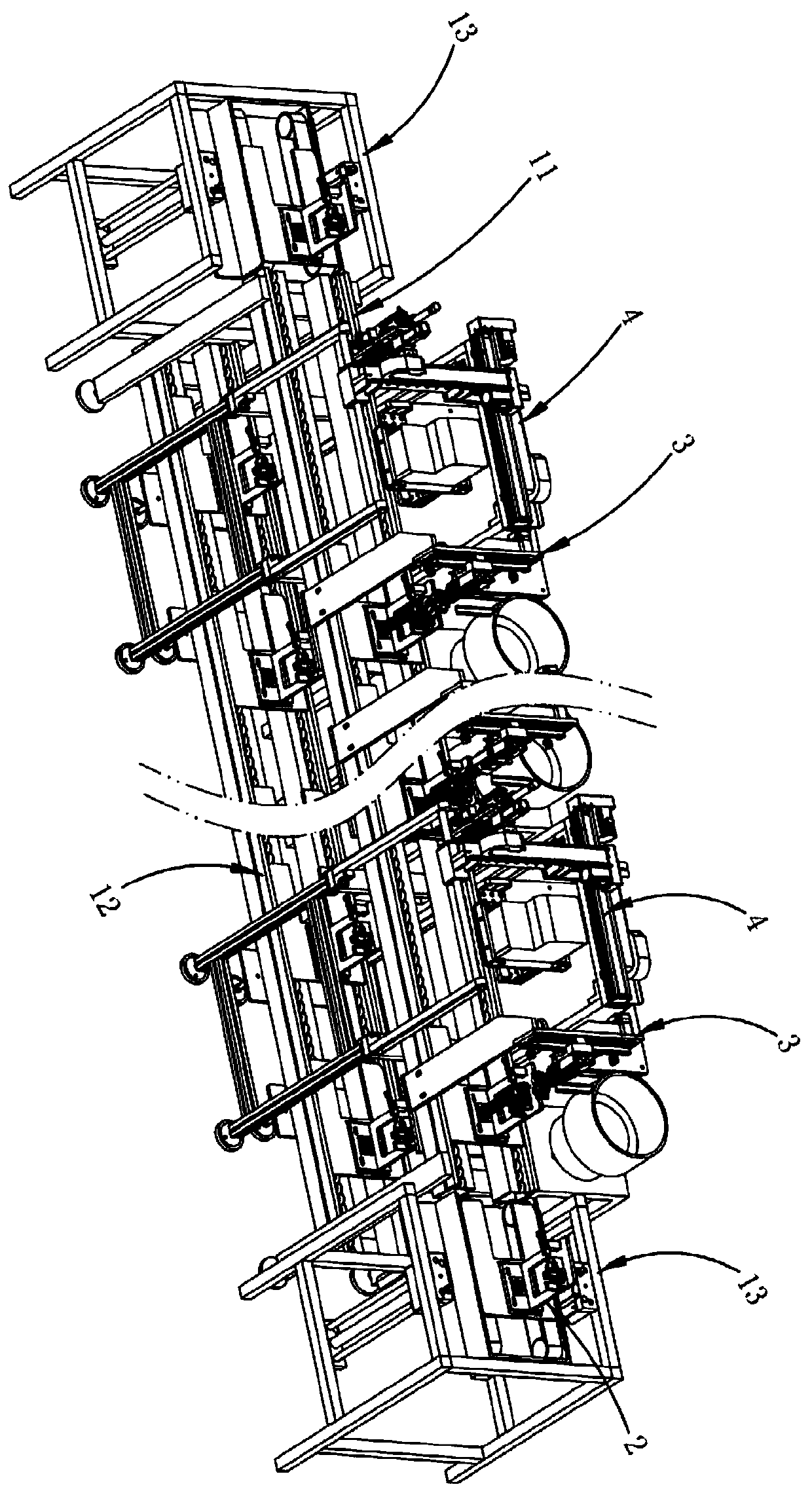

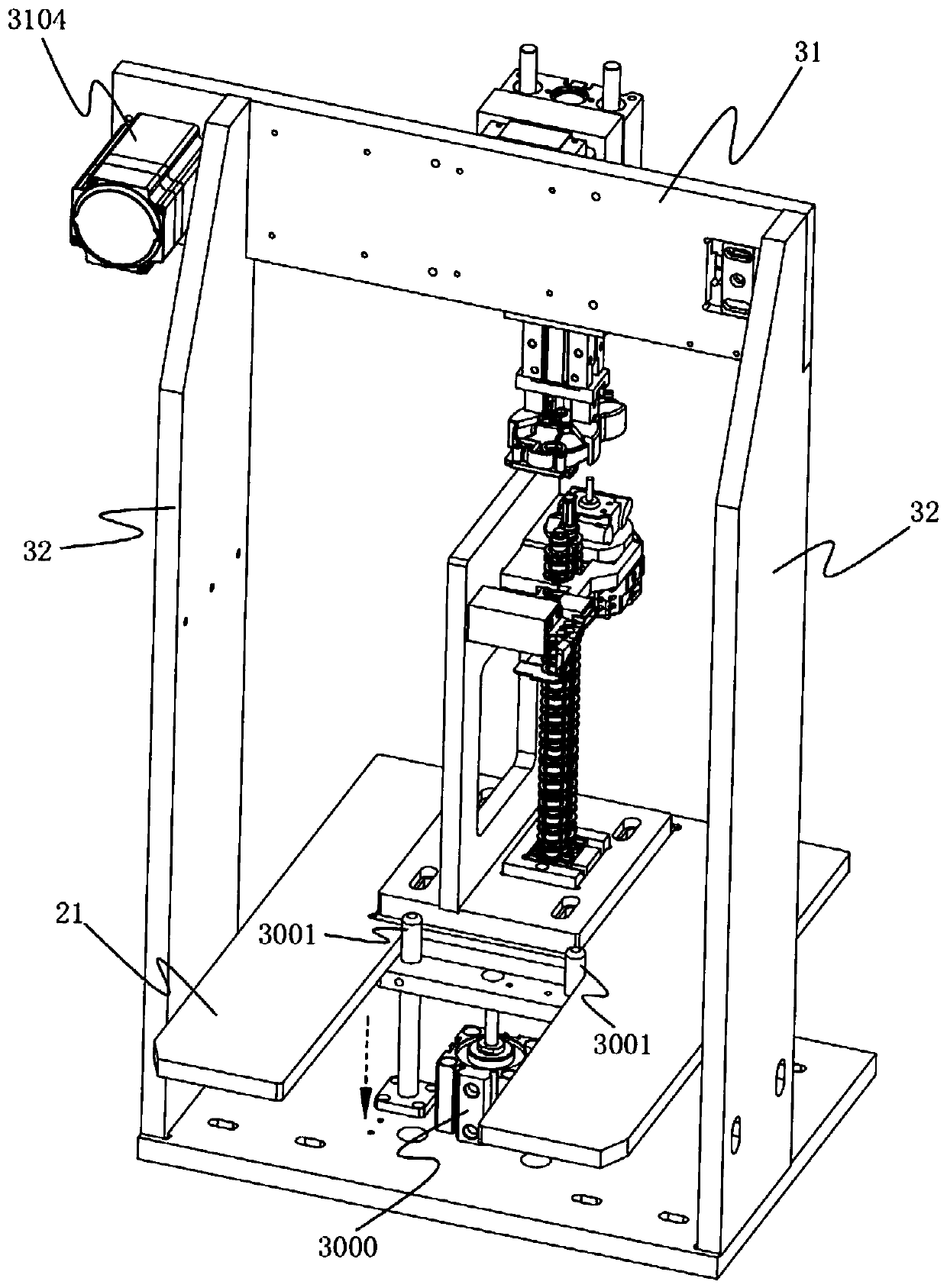

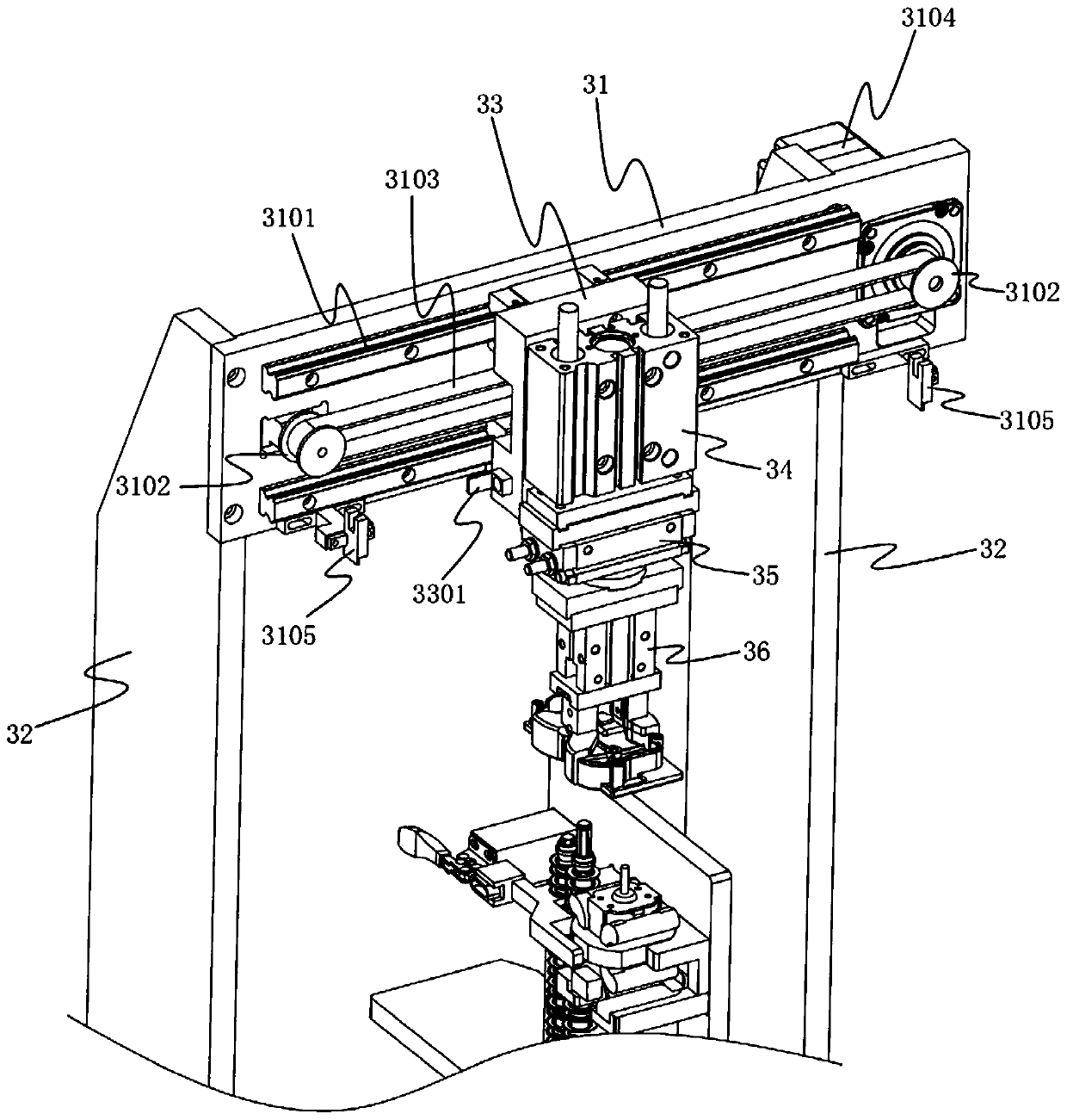

[0040] A paper shredder core assembly equipment, such as Figure 1 to Figure 13 Shown, comprise the frame that upper and lower layers are arranged, the upper strata of frame is provided with advancing conveying line 11, and the upper strata of frame is provided with return conveying line 12, and the end of advancing conveying line 11 is connected with the beginning of return conveying line 12, returns conveying line The end of 12 is connected to the beginning of the forward conveyor line 11, and the forward conveyor line 11 and the return conveyor line 12 are connected to form a rotary conveyor line; a plurality of tooling racks 2 are arranged on the rotary conveyor line, and each tooling rack 2 is respectively provided with At least one workpiece positioning unit and clamping device, each clamping device cooperates with each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com