Thin aluminum plate middle grooving machining tool

A technology for groove processing and thin aluminum plate, which is applied in the field of groove processing tooling in the middle of thin aluminum plate, can solve the problems of difficulty in meeting the size, roughness of the shape, no longer meeting the production requirements of the enterprise, and movement under force, etc. Small deformation, the effect of reducing the clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

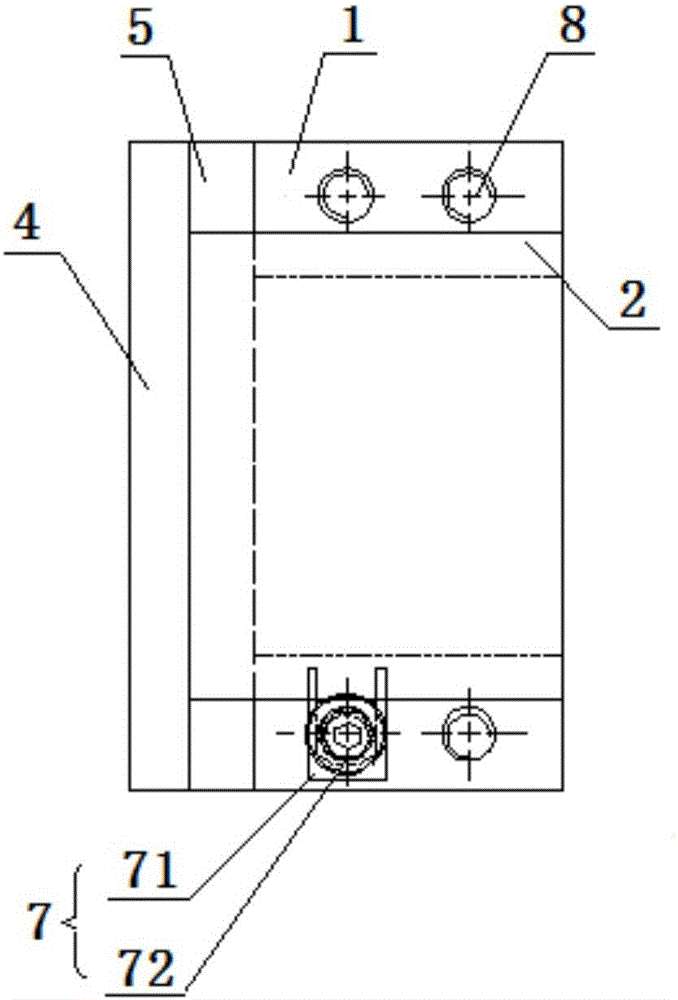

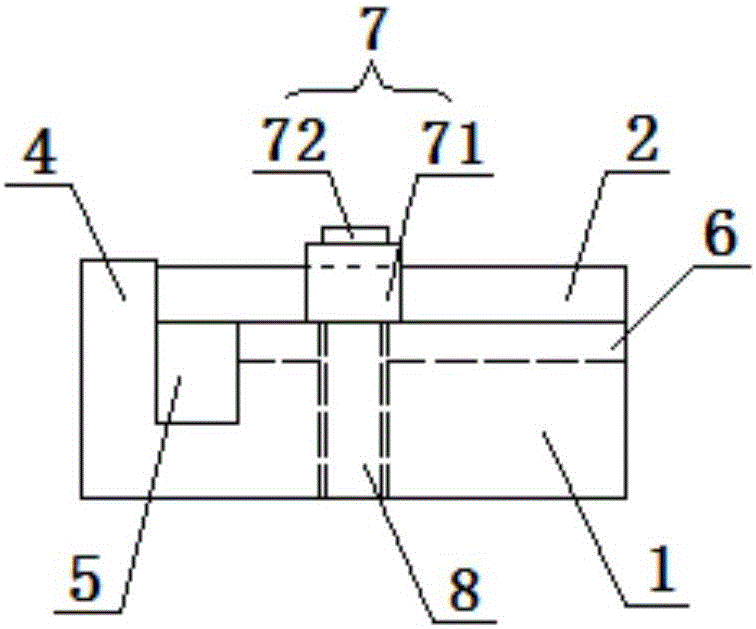

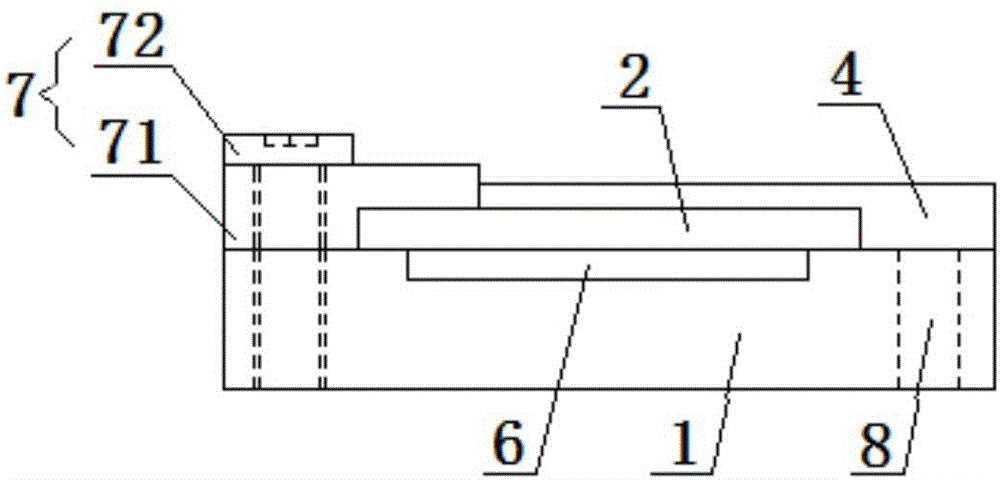

[0027] refer to Figure 1-8 , a middle slotting processing tool for a thin aluminum plate of the present invention, comprising a base 1 that can be connected to a machine tool, and two ends of the base 1 are symmetrically provided with a protruding rectangular positioning that matches the bottom surface of the workpiece 2 to be processed. surface 3, the workpiece 2 is placed on the positioning surface 3, and the side edge of the base 1 is provided with a strip-shaped positioning boss 4 that is vertical and higher than the positioning surface 3. The matching planar structure is used for positioning the left and right directions of the workpiece 2. A tool feed groove 5 for tool feeding is provided on the base 1 between the positioning boss 4 and the positioning surface 3. Giving the groove 5 is a groove vertically concave downward from the positioning surface 3, and the cutter feeding groove 5 is a long groove arranged longitudinally along the feeding direction of the cutter and...

specific Embodiment 2

[0030] refer to Figure 9 As shown, it is another specific embodiment of the present invention, which is basically the same as Embodiment 1, except that the locking connector includes a connecting bolt 73 that is compatible with the threaded hole 8 and locks the pressing block 71 at the same time. The lock nut 74 tightened on the workpiece 2 and the positioning surface 3, when the workpiece 2 is clamped, the connecting bolt 73 passes through the threaded hole 8 from the bottom or top of the base 1, and then is positioned and locked by the annular bottom surface of the lock nut 74, Or it can be locked by the shoulder of the bolt, which is convenient for clamping, and it adopts the locking method of the bolt and the nut, which can prevent the screw from loosening during the processing of the workpiece 2, which will cause the workpiece 2 to shake and cause the problem that it cannot be processed , improving the stability of workpiece 2 processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com