Two-rotating one-moving parallel mechanism provided with symmetric structure and continuous rotating shaft

A technology of symmetrical structure and rotating shaft, applied in the field of robots, can solve the problems of non-isotropic mechanism, few continuous rotating shafts, asymmetry, etc., and achieve the effect of good isotropy, completely symmetrical structure and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

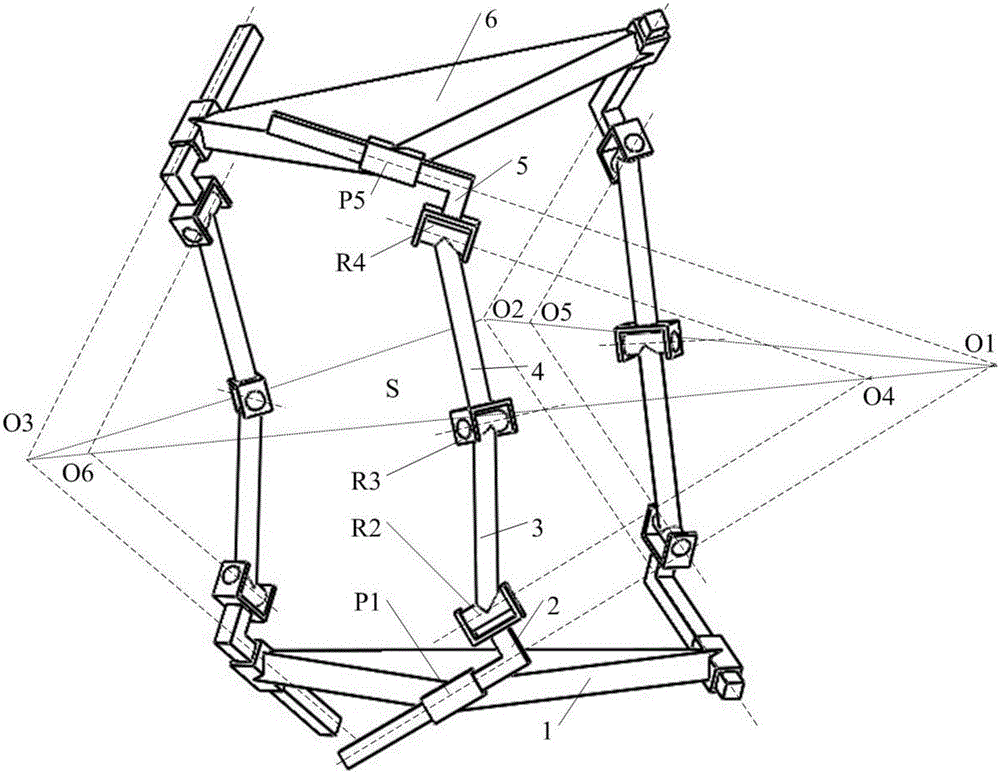

[0012] exist figure 1 In the two-turn-one-shift parallel mechanism with a symmetrical structure and a continuous shaft, three motion branches with the same structure are connected to the fixed platform 1 and the moving platform 6, and the moving pair P1 of the fixed platform in the above three motion branches is connected to the fixed platform. And it is arranged obliquely relative to the fixed platform, the lower rotating pair R2 is connected with the moving pair P1 of the fixed platform through the first connecting rod 2, and the axis of the lower rotating pair R2 is parallel to the axis of the moving pair P1 of the fixed platform, and the middle rotating pair R3 passes through the second The connecting rod 3 is connected with the lower swivel pair R2, the upper swivel pair R4 is connected with the middle swivel pair R3 through the third connecting rod 4, and the axis of the middle swivel pair R3 is neither intersected nor perpendicular to the axes of the upper and lower swiv...

Embodiment 2

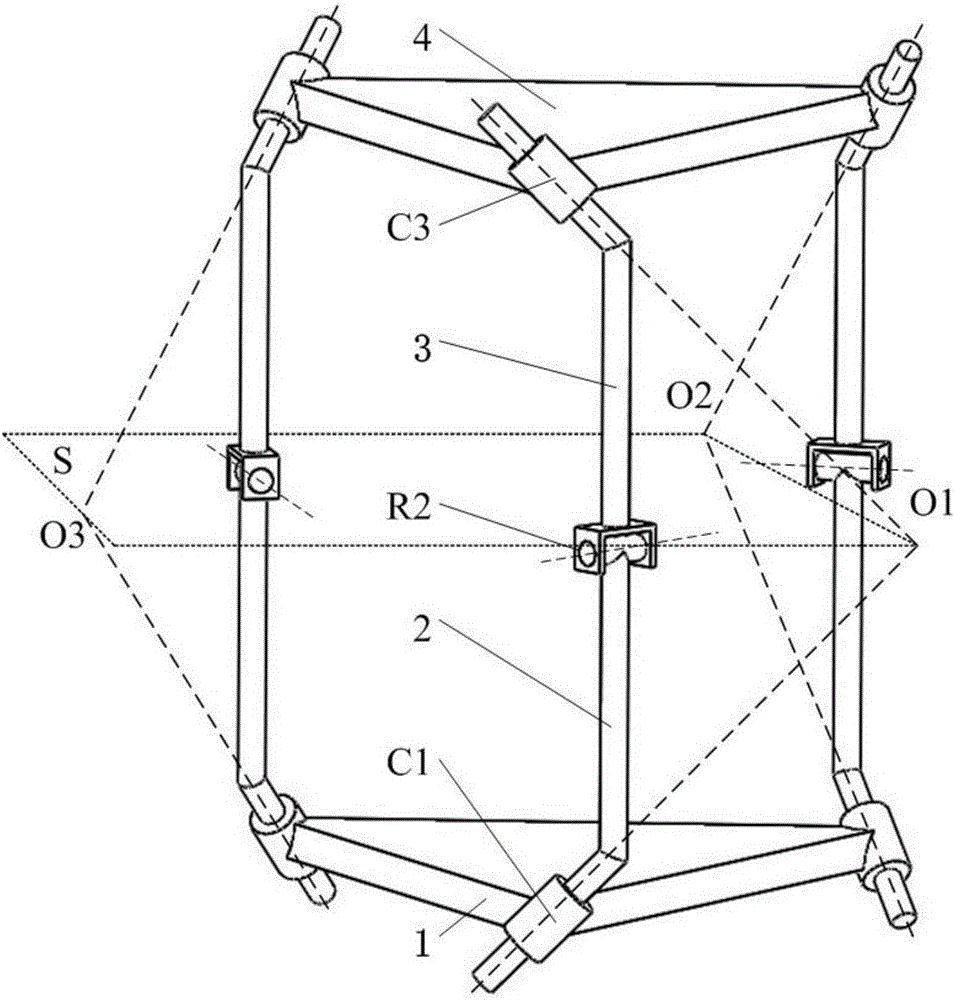

[0014] Such as figure 2 As shown, three motion branches with exactly the same structure are connected to the fixed platform 1 and the moving platform 6. Among the three motion branches, the fixed platform cylinder pair C1 is connected to the fixed platform, and the fixed platform cylinder pair C1 is connected to the middle rotating pair through the first connecting rod 2. R2 is connected, and the middle revolving pair R2 is connected with the cylinder pair C3 of the moving platform through the second connecting rod, and the cylinder pair C3 of the moving platform is connected with the moving platform. The axes of the cylinder pair C3 of the moving platform and the cylinder pair C1 of the fixed platform intersect at a point O1 in space, which is the branch center point, and the branch center points O1, O2 and O3 of the three motion branches form an intermediate symmetry plane S; each motion branch Among them, the kinematic pair combination composed of the fixed platform cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com