A pu round foam high pressure foaming unit

一种高压发泡、机组的技术,应用在发泡机组领域,能够解决泡沫性能不均、混合不均、孔径不均等问题,达到物理性能好、均匀效果好、孔径均匀细腻的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

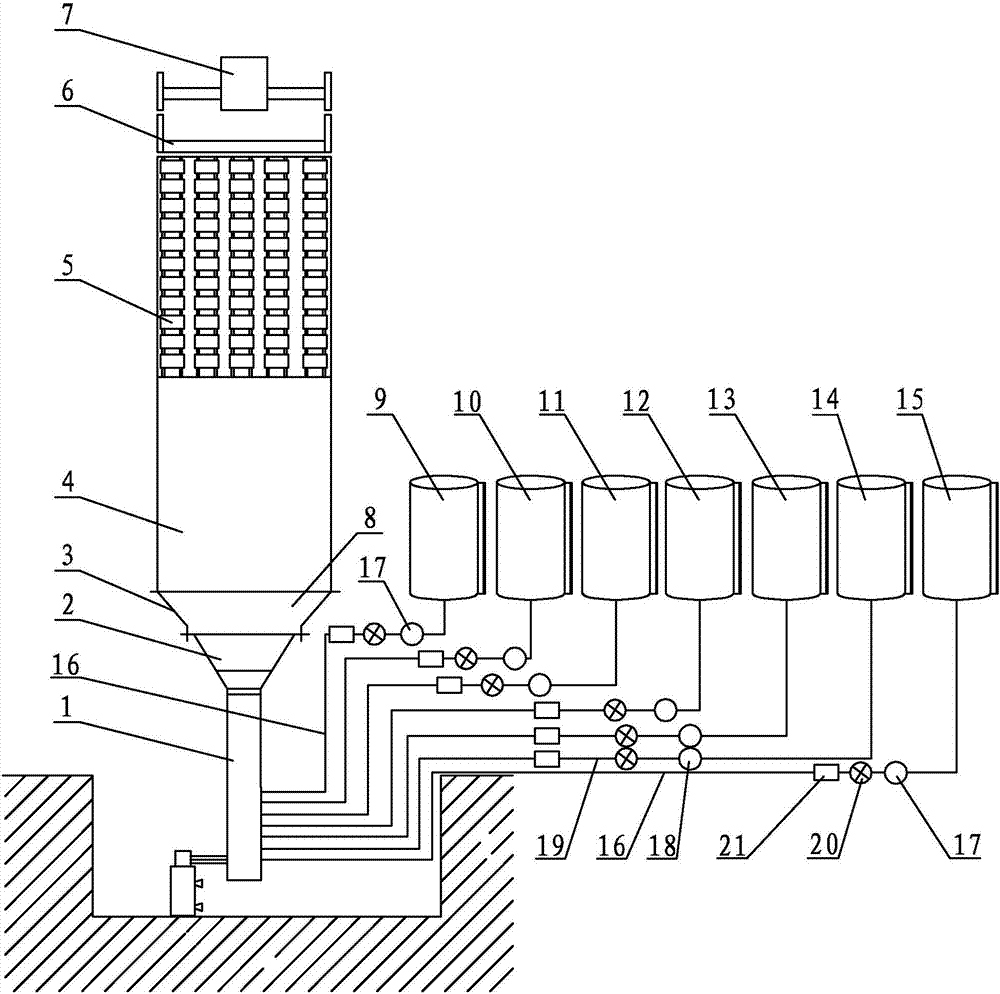

[0019] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this embodiment, this embodiment comprises mixing head 1, conical shaft 2, circular shaft 4, chain plate drive cylinder 5, cutting mechanism 6, bubble-entrapping mechanism 7, cylindrical plastic film 8, the first raw material tank 9, The second raw material tank 10, the third raw material tank 11, the fourth raw material tank 12, the fifth raw material tank 13, the sixth raw material tank 14, the seventh raw material tank 15, two low-pressure feed pipes 16, two low-pressure pumps 17, Three connecting rods 3, five high-pressure pumps 18, five high-pressure feed pipes 19, seven flowmeters 20 and seven pressure gauges 21,

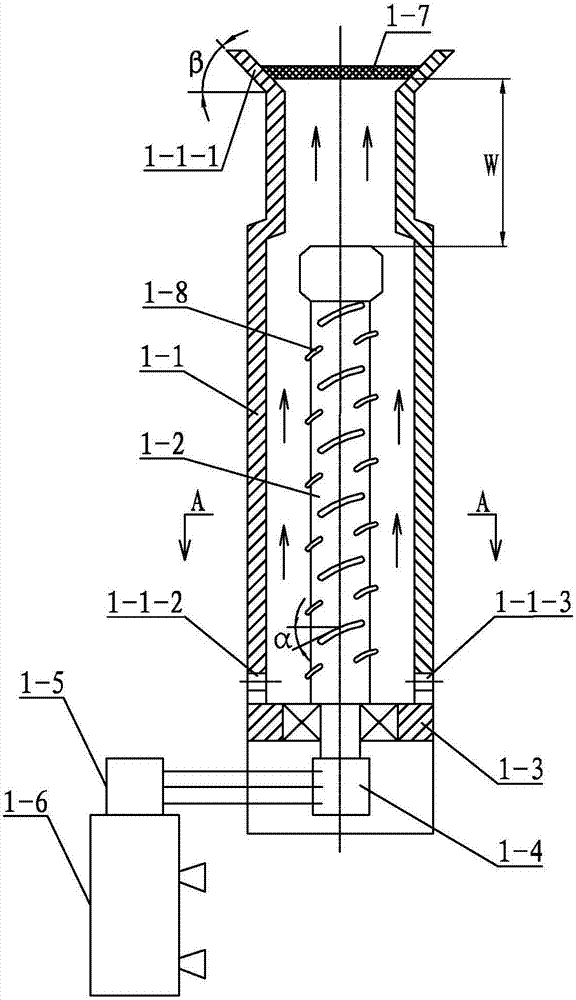

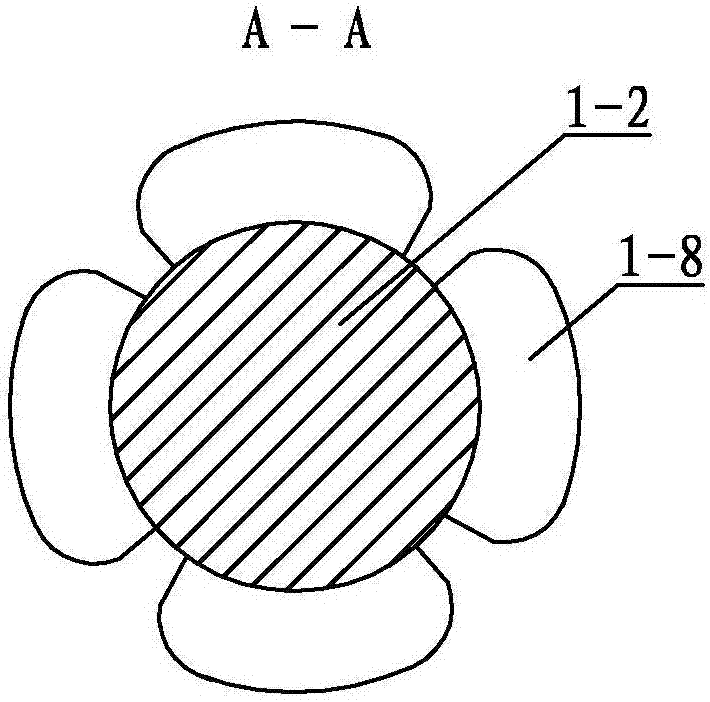

[0020] The mixing head 1 includes a housing 1-1, a stirring shaft 1-2, a base 1-3, a driven pulley 1-4, a driving pulley 1-5, a stirring motor 1-6, a balance grid 1-7 and several Blades 1-8,

[0021] The stirring shaft 1-2 is set in the housing 1-1, the lower end of the stirring s...

specific Embodiment approach 2

[0026] Specific implementation mode two: combination figure 2 The present embodiment will be described. The height of the pressure buffer zone W in the present embodiment is 150 mm to 300 mm. The pressure buffer W increases the space of the cavity, and the longer cavity makes the raw materials mix continuously while reducing the multi-directionality of the pressure and flow rate brought by the vortex speed. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0027] Specific implementation mode three: combination figure 2 The present embodiment will be described. The height of the pressure buffer zone W in the present embodiment is 250 mm. The pressure buffer W increases the space of the cavity, and the longer cavity makes the raw materials mix continuously while reducing the multi-directionality of the pressure and flow rate brought by the vortex speed. Other components and connections are the same as those in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com