Full-automatic production system for paper containers

A production system, fully automatic technology, applied in the direction of paper/cardboard containers, containers, container manufacturing machinery, etc., can solve the problems of unreasonable design and easy splashing of liquid in the cup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

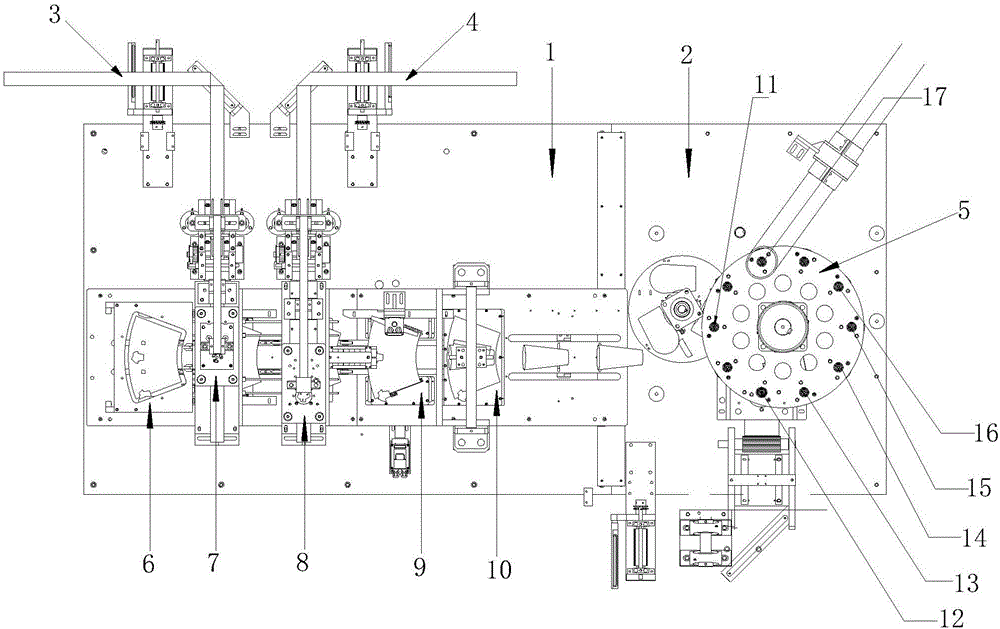

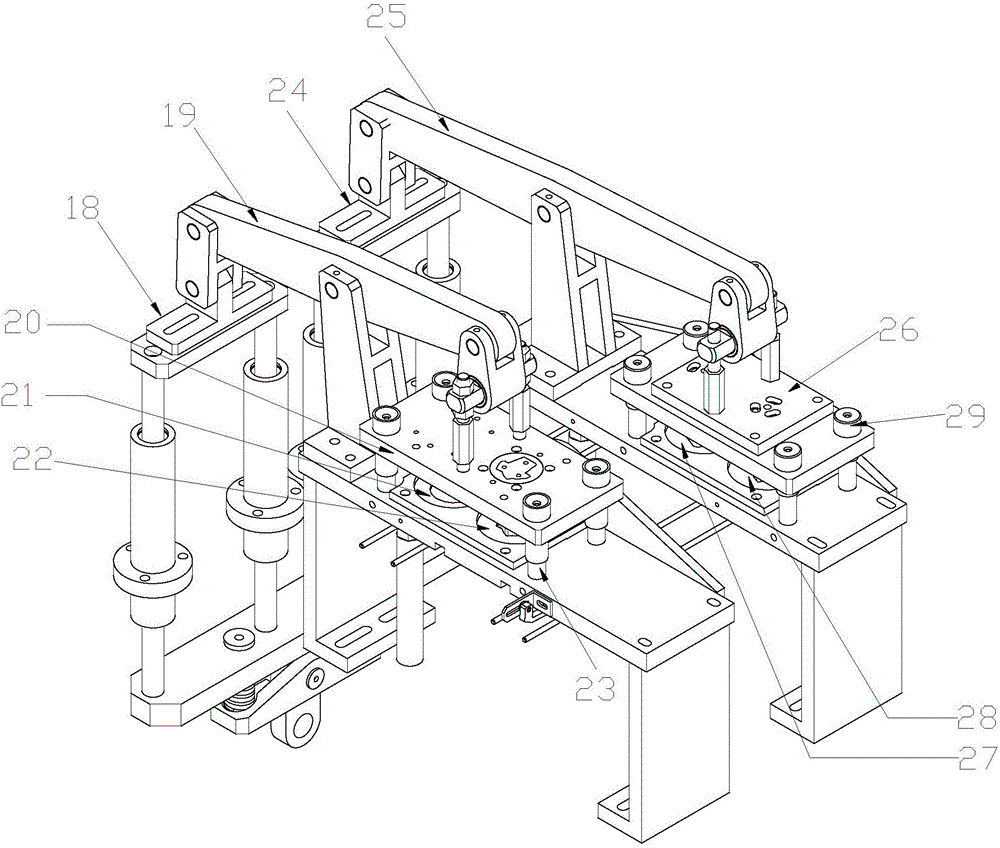

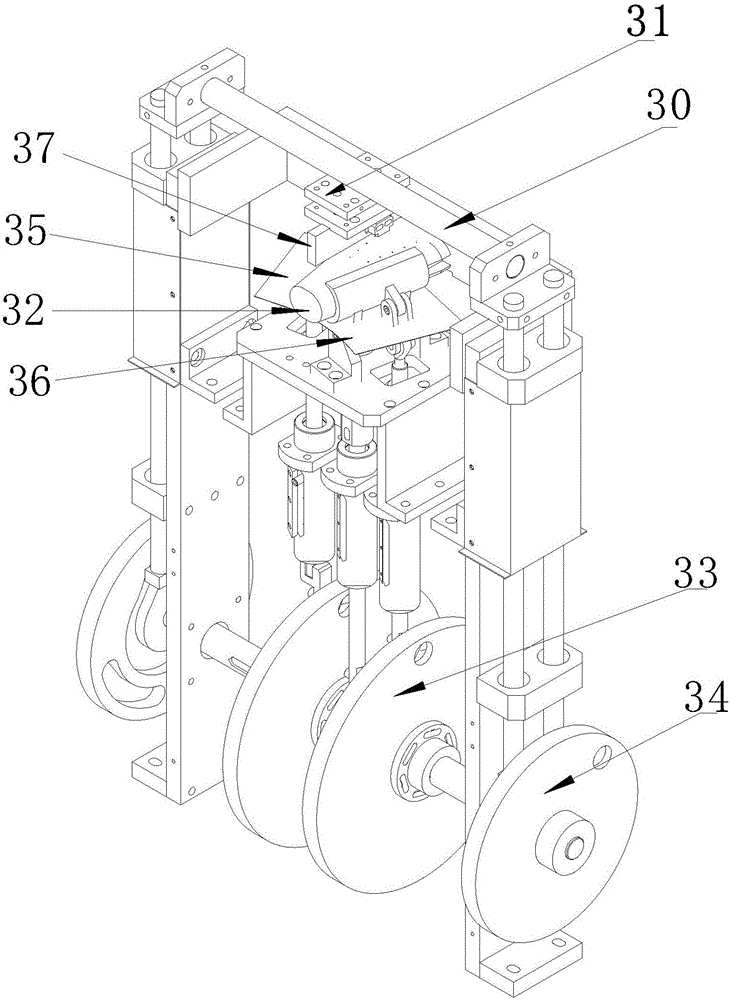

[0015] As shown in the figure, an embodiment of the fully automatic production system for paper containers of the present invention is provided, including a front frame 1 and a rear frame 2, and the front frame 1 is sequentially provided with a paper suction mechanism 6 and a left splash guard for cutting Fixing mechanism 7, right splash guard cutting and fixing mechanism 8, heating mechanism 9, page-holding welding mechanism 10, said rear frame 2 is provided with a multi-station indexing turntable 5, said multi-station indexing turntable 5 There are top cup cylinder station 11, cup bottom paper punching station 12, primary hot air station 13, secondary hot air station 14, rotating bottom rolling station 15, rotating bottom rolling station 16, and cup dropper. Position 17, the paper suction mechanism 6, the left splash-proof sheet cutting and fixing mechanism 7, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com