Silk screen printer

A technology of screen printing machine and printing device, applied in screen printing machine, printing machine, rotary printing machine and other directions, can solve the problems of low adjustability, poor printing effect, unsatisfactory drying effect, etc., so as to improve the traction The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

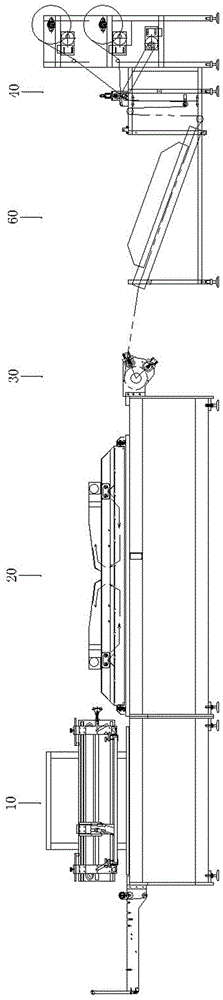

[0015] Refer to attached figure 1 , a screen printing machine, including a printing device 10, a drying device 20, a traction device 30 and a winding device 40 arranged in sequence. The printing device 10 is an existing technology, and the printing principle is as follows: through the extrusion of the scraper, the ink is transferred to the substrate through the mesh of the graphic part to form the same graphic as the original.

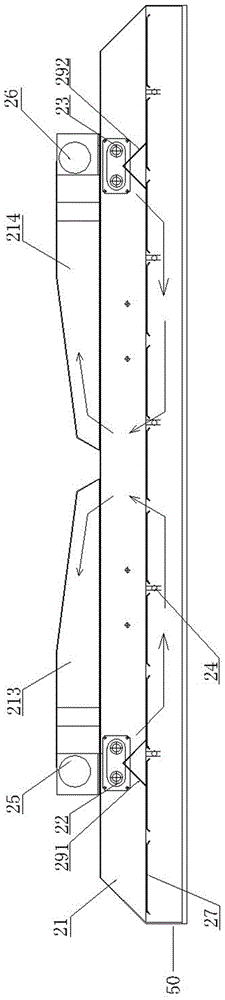

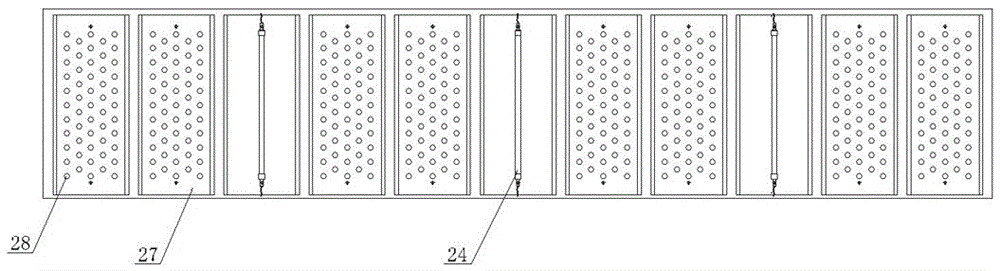

[0016] Refer to attached figure 2 And attached image 3 The drying device 20 includes a box body 21, a front heating pipe 22, a rear heating pipe 23, an infrared lamp 24, a front fan 25, a rear fan 26, several ventilation panels 27, and a front splitter 291 and a rear splitter 292. , the box body 21 is a cuboid, and the several pieces of ventilation panels 27 are spliced to form a ventilation device. It is arranged in the splicing gap of the ventilation plate 27, so that the hot air heated by the heating pipe passes through the ventilation plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com