An automatic test tube coding device

A test tube coding and test tube technology, applied in the field of medical equipment, can solve the problems of high price, complex structure, and large space occupied by equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

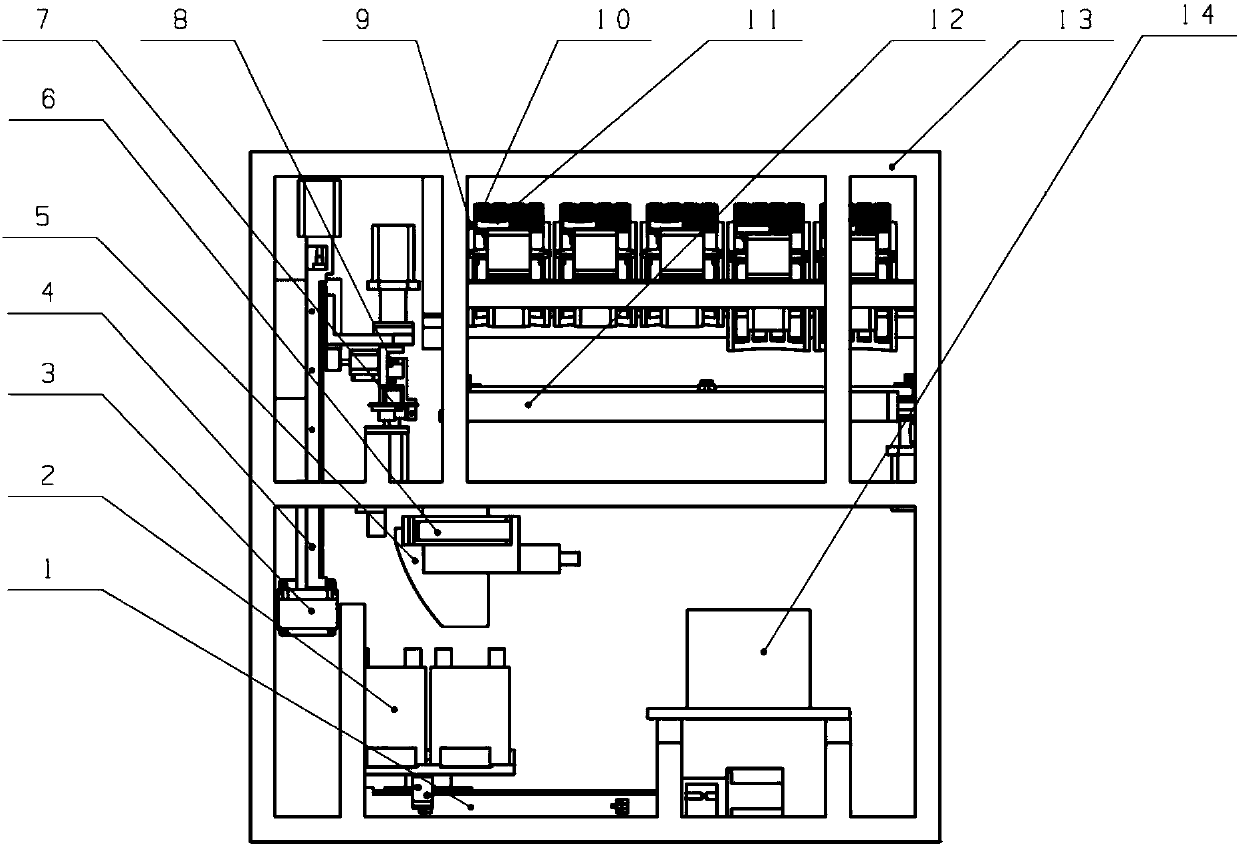

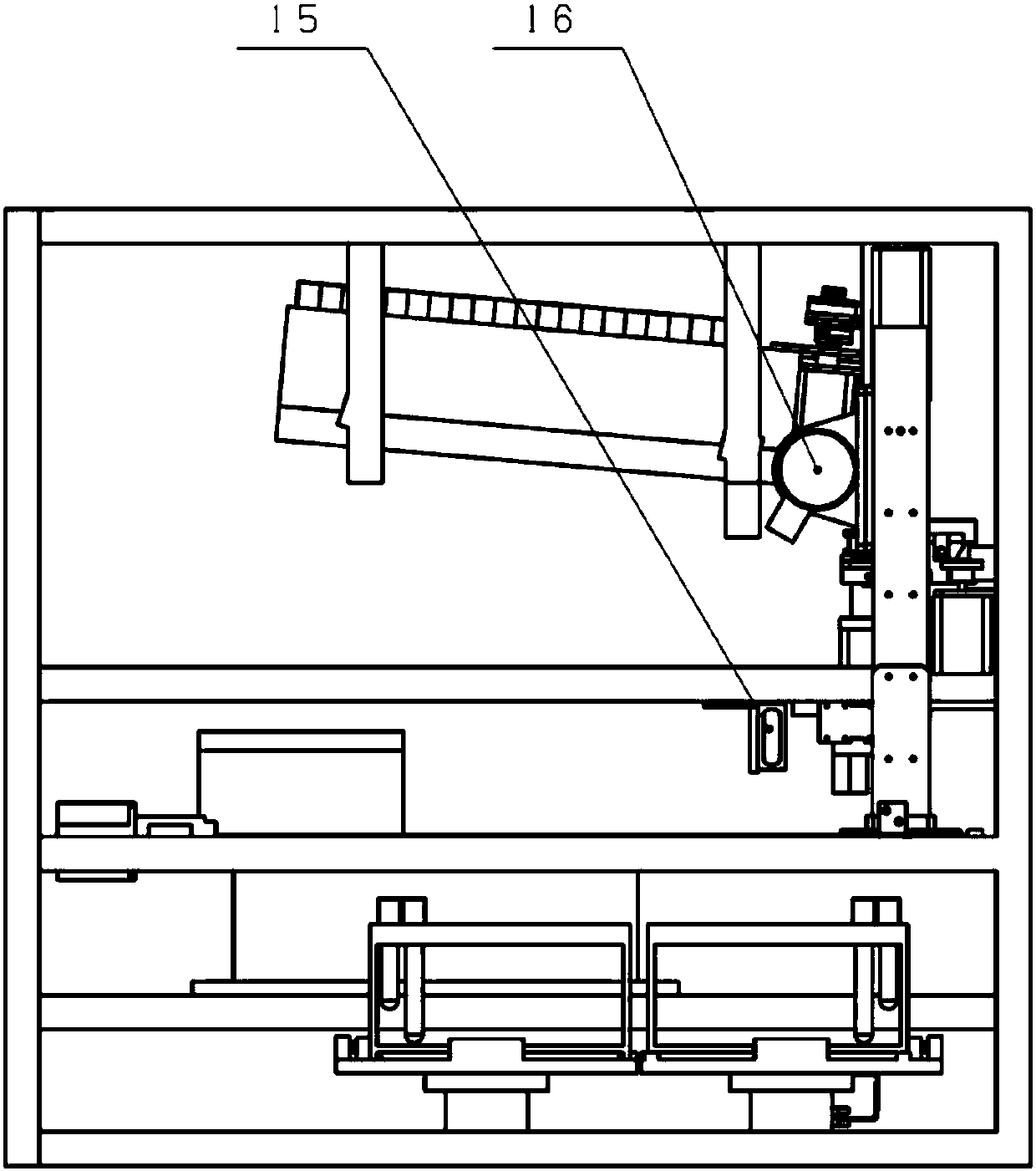

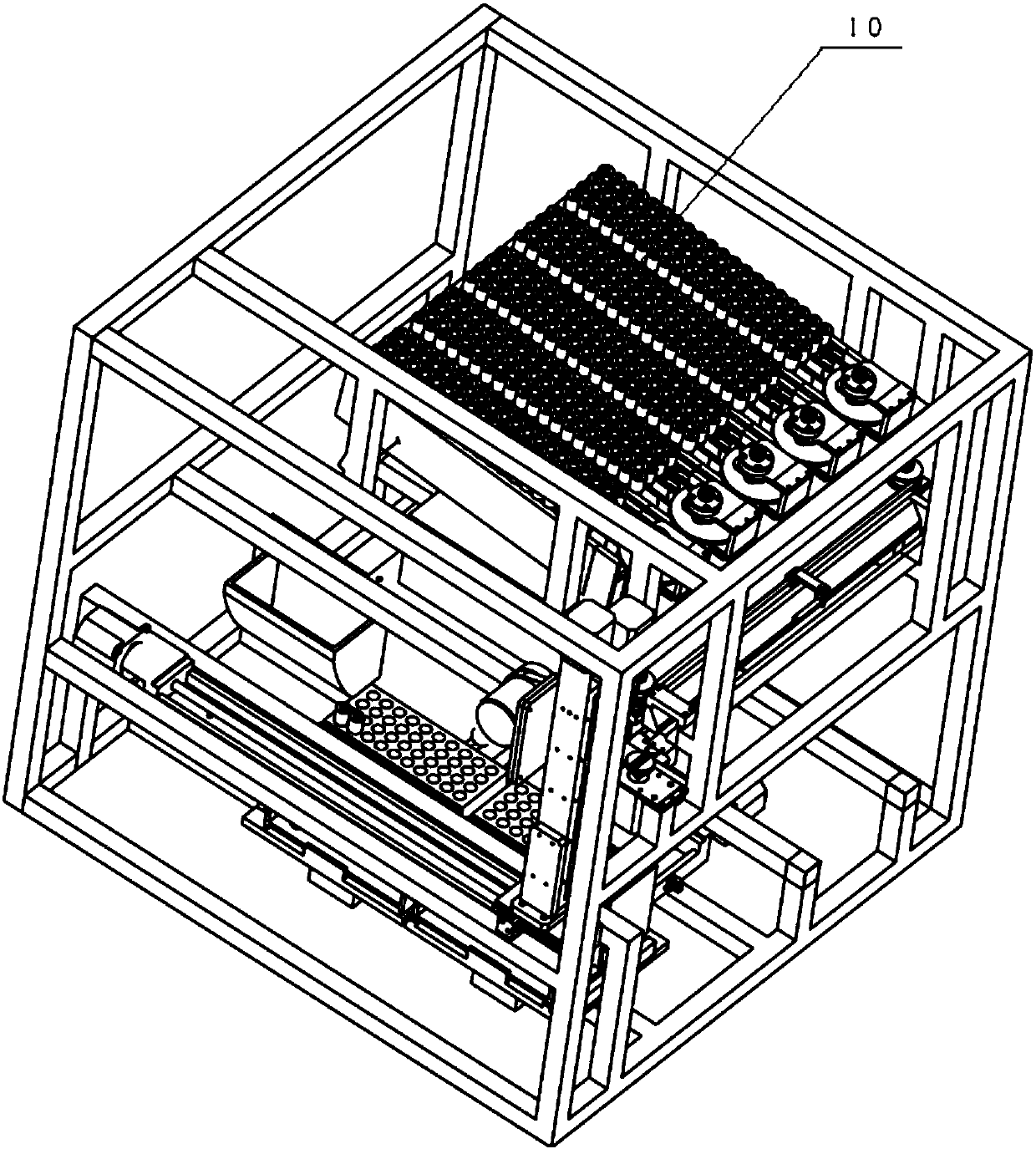

[0018] Such as Figure 1-3 As shown, the automatic test tube coding device according to the present invention includes: a main body, a test tube rack to be sprayed, a test tube positioning device, a test tube transport indexing device, a test tube grabbing device, a coding and verification device, and a test tube after spraying shelf.

[0019] Specifically, the automatic test tube coding device according to the present invention includes: an X-direction movement mechanism 1, a test tube rack 2 after spraying, a Y-direction movement mechanism 3, a Z-direction movement mechanism 4, a waste test tube collection box 5, and a jetting terminal 6 , test tube transport indexing device 7, test tube clamp 8, test tube rack to be sprayed 9, test tube to be sprayed 10, test tube selection indexing device 11, test tube transport device 12, frame structure 13, inkjet printer host 14, barcode inspection device 15, Coding synchronization device 16.

[0020] Such as figure 1 As shown, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com